- Home

-

Trailers

- Box Trailers >

-

Flat Top/Flat Bed Trailers

>

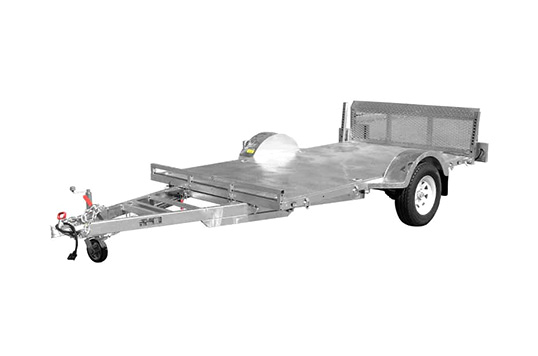

- Single Axle Flatbed Trailers >

-

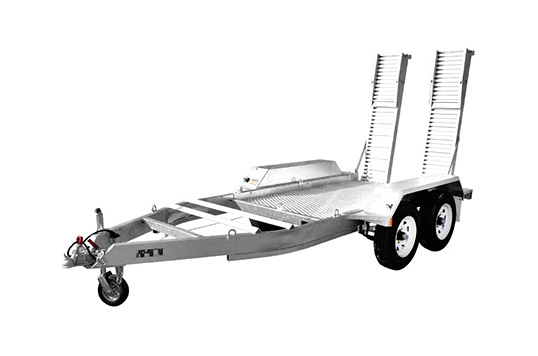

Tandem Axle Flatbed Trailers

>

-

8×5ft ATM 1990KG Flat Top /Flat Bed TrailerTrail...

8×5ft ATM 1990KG Flat Top /Flat Bed TrailerTrail... -

10×6.3ft ATM 2800KG Flat Top /Flat Bed Tandem TrailerTrail...

10×6.3ft ATM 2800KG Flat Top /Flat Bed Tandem TrailerTrail... -

10×6ft ATM 3500KG Flat Top /Flat Bed Hydraulic Tipper TrailerTrail...

10×6ft ATM 3500KG Flat Top /Flat Bed Hydraulic Tipper TrailerTrail... -

12×7ft ATM 3500KG Flat Top /Flat Bed Tandem TrailerTrail...

12×7ft ATM 3500KG Flat Top /Flat Bed Tandem TrailerTrail... -

14×7ft 3500KG ATM Flat Bed Tandem TrailerTrail...

14×7ft 3500KG ATM Flat Bed Tandem TrailerTrail... -

12×7ft ATM 3500KG Tandem Flatbed Hydraulic Tipper TrailerTrail...

12×7ft ATM 3500KG Tandem Flatbed Hydraulic Tipper TrailerTrail...

-

- Tri Axle Flatbed Trailers >

- Hydraulic Tippers >

- Cattle/ Livestock Trailers >

-

Boat, Kayak & Jet Ski Trailers

>

-

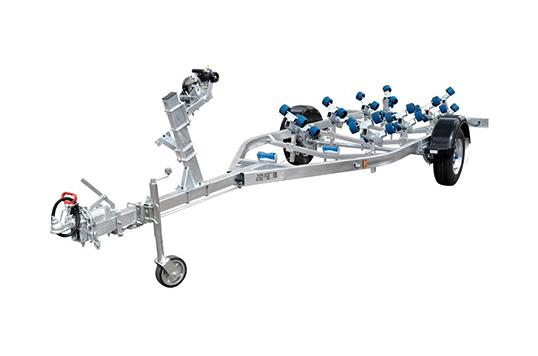

Single Axle Rollers Boat Trailer

>

-

4100 Series 750KG ATM Single Axle Rollers Boat TrailerTrail...

4100 Series 750KG ATM Single Axle Rollers Boat TrailerTrail... -

4500 Series 750KG ATM Single Axle Rollers Boat TrailerTrail...

4500 Series 750KG ATM Single Axle Rollers Boat TrailerTrail... -

4900 Series 1200KG ATM Single Axle Rollers Boat TrailerTrail...

4900 Series 1200KG ATM Single Axle Rollers Boat TrailerTrail... -

5700 Series 1500KG ATM Single Axle Rollers Boat TrailerTrail...

5700 Series 1500KG ATM Single Axle Rollers Boat TrailerTrail... -

6300 Series 1500KG ATM Single Axle Rollers Boat TrailerTrail...

6300 Series 1500KG ATM Single Axle Rollers Boat TrailerTrail...

-

- Single Axle Skid Boat Trailer >

- Tandem Axle Rollers Boat Trailer >

- Kayak & Canoe Trailer >

-

Single Axle Rollers Boat Trailer

>

- Motorcycles, ATV & Buggy Trailers >

- Car & Plant Trailers >

- Gardening & Mowing Trailers >

-

Builders/Tradesman Trailers

>

-

Single Axle Fully Enclosed & Luggage Trailer

>

-

6×4ft Small Tradesman/ Builders TrailerTrail...

6×4ft Small Tradesman/ Builders TrailerTrail... -

7×4ft Tradesman/ Builders TrailerTrail...

7×4ft Tradesman/ Builders TrailerTrail... -

7×5ft Tradesman/ Builders Trailer with Aluminium CanopyTrail...

7×5ft Tradesman/ Builders Trailer with Aluminium CanopyTrail... -

8×5ft Durable Tradesman/ Builders TrailerTrail...

8×5ft Durable Tradesman/ Builders TrailerTrail... -

8×6ft ATM 750KG Tradesman/ Builders TrailerTrail...

8×6ft ATM 750KG Tradesman/ Builders TrailerTrail... -

7×5ft Heavy Duty Tradesman/ Builders TrailerTrail...

7×5ft Heavy Duty Tradesman/ Builders TrailerTrail... -

8×5ft Heavy Duty ATM 1400KG Tradesman/ Builders TrailerTrail...

8×5ft Heavy Duty ATM 1400KG Tradesman/ Builders TrailerTrail... -

8×6ft Heavy Duty Enclosed Tradesman/ Builders TrailerTrail...

8×6ft Heavy Duty Enclosed Tradesman/ Builders TrailerTrail...

-

-

Tandem Axle Builders/Tradesman Trailer

>

-

8×5ft Dual Axle Builders/Tradesman TrailerTrail...

8×5ft Dual Axle Builders/Tradesman TrailerTrail... -

10×5ft Tandem Builders/Tradesman TrailerTrail...

10×5ft Tandem Builders/Tradesman TrailerTrail... -

10×6ft Tandem Builders/Tradesman TrailerTrail...

10×6ft Tandem Builders/Tradesman TrailerTrail... -

8×5ft Tandem Axle Tradesman/ Builders TrailerTrail...

8×5ft Tandem Axle Tradesman/ Builders TrailerTrail... -

10×5ft Tandem Tradesman/ Builders TrailerTrail...

10×5ft Tandem Tradesman/ Builders TrailerTrail... -

10×6ft Tandem Tradesman/ Builders Trailer with Aluminium CanopyTrail...

10×6ft Tandem Tradesman/ Builders Trailer with Aluminium CanopyTrail...

-

-

Single Axle Fully Enclosed & Luggage Trailer

>

- Enclosed/Luggage Trailers >

-

Toolboxes

-

Under Tray Toolboxes

>

-

Ute Under Tray Toolboxes

>

-

580 x 230 x 400mm Aluminium Checker Ute Toolbox Truck Storage Under Body Tray Storage Strap Tool BoxThickness:...

580 x 230 x 400mm Aluminium Checker Ute Toolbox Truck Storage Under Body Tray Storage Strap Tool BoxThickness:... -

600 x 200 x 400mm Aluminium 20L Ute Camping Under Tray Body Box Storage Water TankThickness:...

600 x 200 x 400mm Aluminium 20L Ute Camping Under Tray Body Box Storage Water TankThickness:... -

600 x 230 x 400mm Aluminium Pair Ute Toolbox Truck Storage Under Body Tray Storage Strap Tool Box Off Road TapperThickness:...

600 x 230 x 400mm Aluminium Pair Ute Toolbox Truck Storage Under Body Tray Storage Strap Tool Box Off Road TapperThickness:... -

600 x 230 x 400mm Aluminium Set Pair Ute Toolbox Truck Storage Under Body Tray Storage Strap Tool Box Off Road TapperThickness:...

600 x 230 x 400mm Aluminium Set Pair Ute Toolbox Truck Storage Under Body Tray Storage Strap Tool Box Off Road TapperThickness:... -

750 x 230 x 400mm Aluminium SET PAIR Ute Toolbox Truck Storage Under Body Tray Storage Strap Tool Box Off Road TapperThickness:...

750 x 230 x 400mm Aluminium SET PAIR Ute Toolbox Truck Storage Under Body Tray Storage Strap Tool Box Off Road TapperThickness:... -

750 x 230 x 400mm Aluminium SET PAIR Ute Toolbox Truck Storage Under Body Tray Storage Strap Tool Box Off Road TapperThickness:...

750 x 230 x 400mm Aluminium SET PAIR Ute Toolbox Truck Storage Under Body Tray Storage Strap Tool Box Off Road TapperThickness:... -

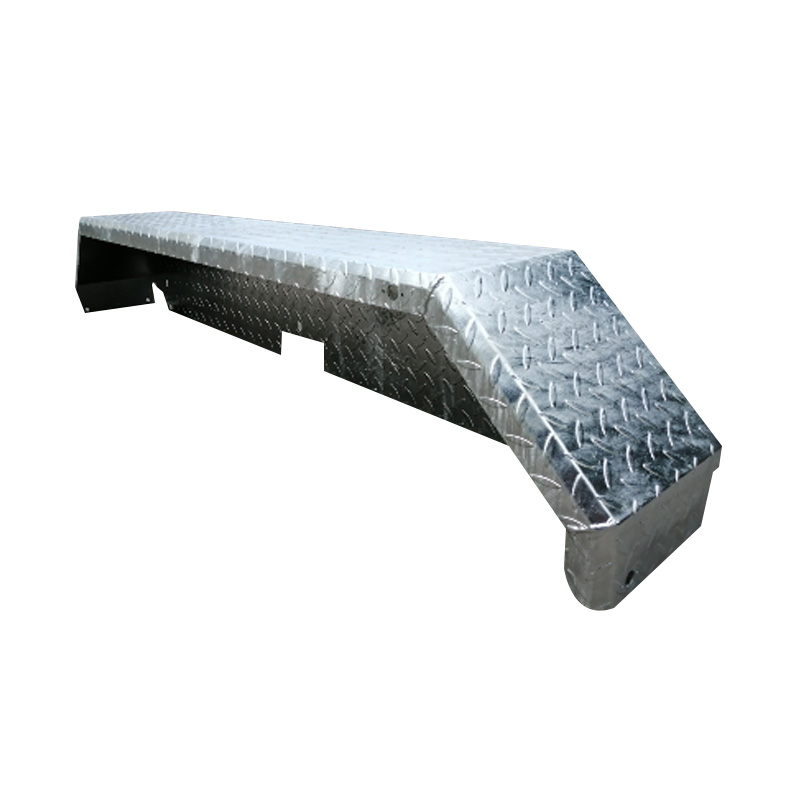

700 x 260 x 400mm (LIMITED EDITION) Under Tray Toolbox TapperedThickness:...

700 x 260 x 400mm (LIMITED EDITION) Under Tray Toolbox TapperedThickness:... -

940 x 230 x 400mm Aluminium SET PAIR Ute Toolbox Truck Storage Under Body Tray Storage Strap Tool Box Off Road TapperThickness:...

940 x 230 x 400mm Aluminium SET PAIR Ute Toolbox Truck Storage Under Body Tray Storage Strap Tool Box Off Road TapperThickness:... -

940 x 230 x 400mm Aluminium SET PAIR Ute Toolbox Truck Storage Under Body Tray Storage Strap Tool Box Off Road TapperThickness:...

940 x 230 x 400mm Aluminium SET PAIR Ute Toolbox Truck Storage Under Body Tray Storage Strap Tool Box Off Road TapperThickness:... -

900 x 260 x 400mm (LIMITED EDITION) Under Tray Toolbox TapperedThickness:...

900 x 260 x 400mm (LIMITED EDITION) Under Tray Toolbox TapperedThickness:...

-

-

Truck Under Tray Boxes

>

-

600 x 450 x 450mm Aluminium Checker Under Tray Body Tool box Truck Storage ToolboxThickness:...

600 x 450 x 450mm Aluminium Checker Under Tray Body Tool box Truck Storage ToolboxThickness:... -

600 x 450 x 450mm Flat Aluminium Under Tray Body Tool box Truck Storage ToolboxThickness:...

600 x 450 x 450mm Flat Aluminium Under Tray Body Tool box Truck Storage ToolboxThickness:... -

900 x 450 x 450mm Flat Aluminium Under Tray Body Tool box Truck Storage ToolboxThickness:...

900 x 450 x 450mm Flat Aluminium Under Tray Body Tool box Truck Storage ToolboxThickness:... -

1000 x 450 x 450mm Flat Aluminium Under Tray Body Tool box Truck Storage ToolboxThickness:...

1000 x 450 x 450mm Flat Aluminium Under Tray Body Tool box Truck Storage ToolboxThickness:... -

1200 x 450 x 450mm Flat Aluminium Under Tray Body Tool box Truck Storage ToolboxThickness:...

1200 x 450 x 450mm Flat Aluminium Under Tray Body Tool box Truck Storage ToolboxThickness:... -

600 x 500 x 500mm Black Aluminium Under Tray Slide Drawer Body Tool box Truck Storage ToolboxThickness:...

600 x 500 x 500mm Black Aluminium Under Tray Slide Drawer Body Tool box Truck Storage ToolboxThickness:... -

900 x 500 x 500mm Raw Flat Aluminium Under Tray Slide Drawer Body Tool box Truck Storage ToolboxThickness:...

900 x 500 x 500mm Raw Flat Aluminium Under Tray Slide Drawer Body Tool box Truck Storage ToolboxThickness:... -

1200 x 500 x 500mm Black Aluminium Under Tray Slide Drawer Body Tool box Truck Storage ToolboxThickness:...

1200 x 500 x 500mm Black Aluminium Under Tray Slide Drawer Body Tool box Truck Storage ToolboxThickness:...

-

-

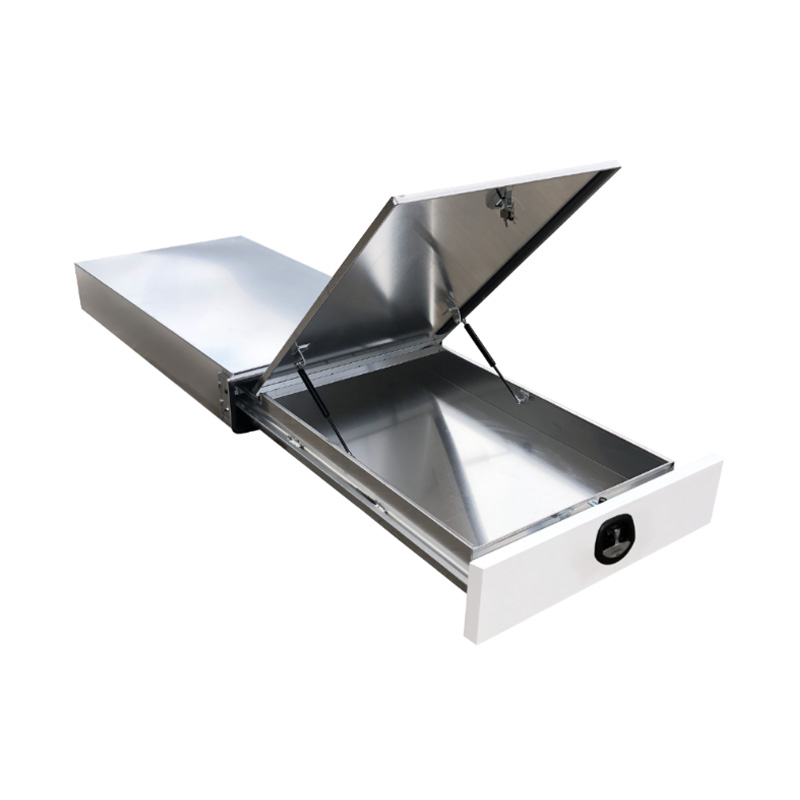

Trundle-Trays

>

-

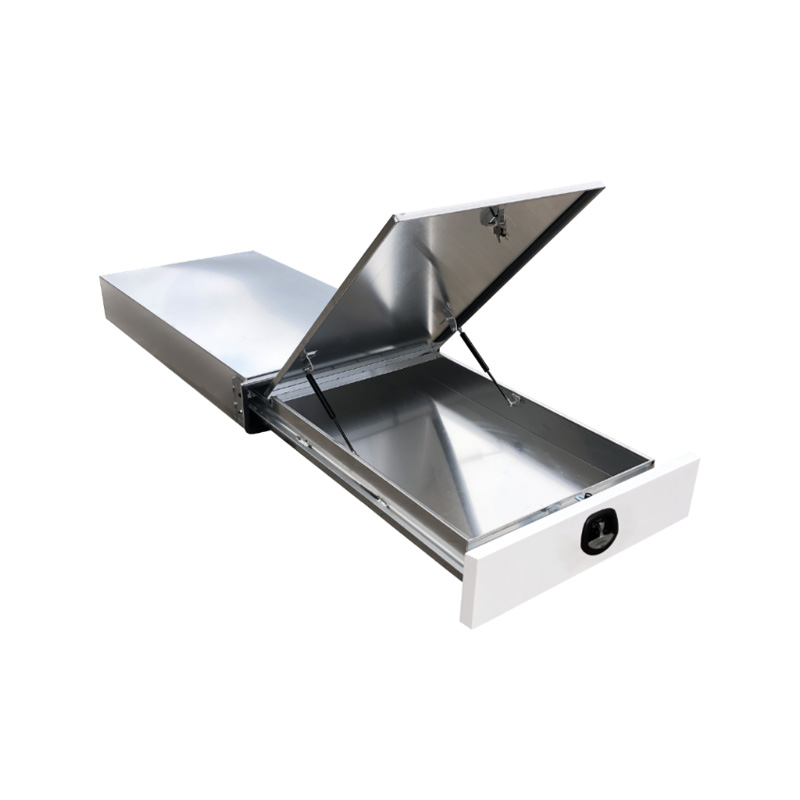

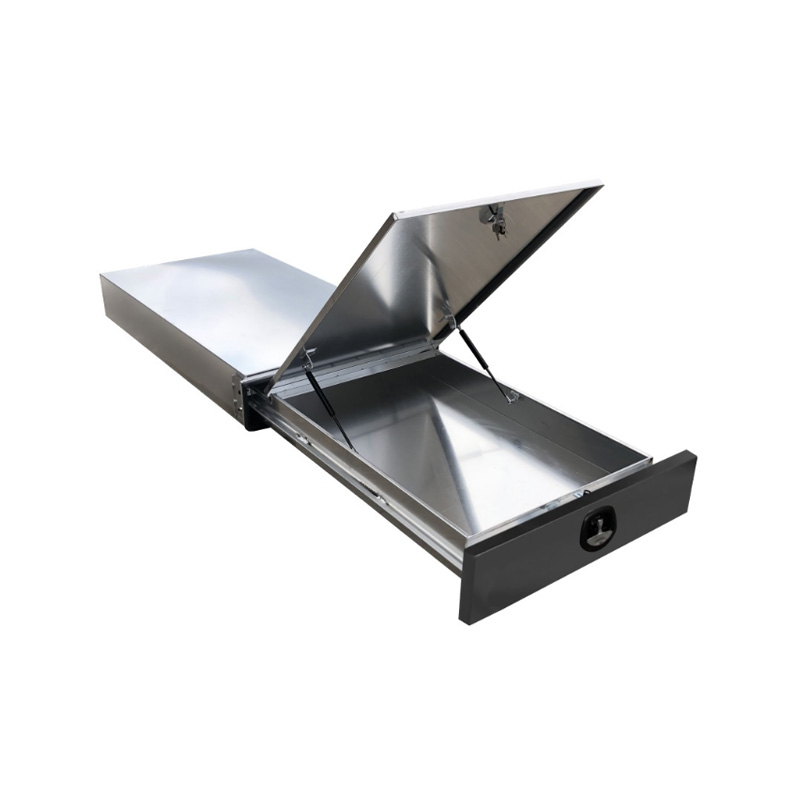

1.4m Aluminium Ute Tool box Under Tray Toolbox Trundle Roller Tray Slide Out Drawer Toolbox Benchtop LidThickness:...

1.4m Aluminium Ute Tool box Under Tray Toolbox Trundle Roller Tray Slide Out Drawer Toolbox Benchtop LidThickness:... -

1.6m Aluminium Ute Tool box Under Tray Toolbox Trundle Roller Tray Slide Out Drawer Toolbox Benchtop LidThickness:...

1.6m Aluminium Ute Tool box Under Tray Toolbox Trundle Roller Tray Slide Out Drawer Toolbox Benchtop LidThickness:... -

1.7m Aluminium Ute Tool box Under Tray Toolbox Trundle Roller Tray Slide Out Drawer Toolbox Benchtop LidThickness:...

1.7m Aluminium Ute Tool box Under Tray Toolbox Trundle Roller Tray Slide Out Drawer Toolbox Benchtop LidThickness:...

-

- Under Tray Water Tanks >

-

Ute Under Tray Toolboxes

>

-

Top Opening Toolboxes

>

-

Rectangle Ute Toolbox

>

-

900 x 400 x 400mm Aluminium Checker Top Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

900 x 400 x 400mm Aluminium Checker Top Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:... -

1220 x 400 x 350mm Aluminium Top Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

1220 x 400 x 350mm Aluminium Top Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:... -

1220 x 500 x 500mm Aluminium Top Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & Canopy 1255Thickness:...

1220 x 500 x 500mm Aluminium Top Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & Canopy 1255Thickness:... -

1500 x 500 x 450mm Aluminium Checker Top Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

1500 x 500 x 450mm Aluminium Checker Top Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:... -

1200 x 600 x 500mm Aluminium Top Chest Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & Canopy(Chest Style)Thickness:...

1200 x 600 x 500mm Aluminium Top Chest Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & Canopy(Chest Style)Thickness:... -

1400 x 600 x 500mm Aluminium Top Chest Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

1400 x 600 x 500mm Aluminium Top Chest Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:... -

1700 x 600 x 500mm Aluminium Top Chest Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

1700 x 600 x 500mm Aluminium Top Chest Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:... -

1200 x 600 x 700mm Aluminium Checker Tool Box Ute Truck Fridge Trailer 3/4 Angle Storage ToolboxThickness:...

1200 x 600 x 700mm Aluminium Checker Tool Box Ute Truck Fridge Trailer 3/4 Angle Storage ToolboxThickness:... -

1400 x 600 x 700mm Aluminium Checker Tool Box Ute Truck Fridge Trailer 3/4 Angle Storage ToolboxThickness:...

1400 x 600 x 700mm Aluminium Checker Tool Box Ute Truck Fridge Trailer 3/4 Angle Storage ToolboxThickness:... -

1500 x 400 x 400mm Aluminium Checker 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:...

1500 x 400 x 400mm Aluminium Checker 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:... -

1500 x 500 x 500mm Raw Flat Aluminium 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:...

1500 x 500 x 500mm Raw Flat Aluminium 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:... -

2000 x 500 x 500mm Aluminium 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:...

2000 x 500 x 500mm Aluminium 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:...

-

-

Chest Style Ute Toolbox

>

-

1500 x 500 x 450mm Aluminium Checker Top Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

1500 x 500 x 450mm Aluminium Checker Top Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:... -

1200 x 600 x 500mm Aluminium Top Chest Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & Canopy(Chest Style)Thickness:...

1200 x 600 x 500mm Aluminium Top Chest Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & Canopy(Chest Style)Thickness:... -

1400 x 600 x 500mm Aluminium Top Chest Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

1400 x 600 x 500mm Aluminium Top Chest Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

-

- Tub Liner Ute Toolbox >

- Job Site Toolbox >

-

Camper Ute Toolbox

>

-

1500 x 400 x 400mm Aluminium Checker 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:...

1500 x 400 x 400mm Aluminium Checker 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:... -

1500 x 500 x 500mm Raw Flat Aluminium 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:...

1500 x 500 x 500mm Raw Flat Aluminium 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:... -

2000 x 500 x 500mm Aluminium 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:...

2000 x 500 x 500mm Aluminium 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:... -

610 x 330 x 540mm Aluminium Checker Ute Toolbox Trailer Camper Caravan Generator Tool Box for Honda 2kvaThickness:...

610 x 330 x 540mm Aluminium Checker Ute Toolbox Trailer Camper Caravan Generator Tool Box for Honda 2kvaThickness:... -

700 x 450 x 650mm Aluminium Checker Ute Toolbox Trailer Camper Caravan Generator Tool BoxThickness:...

700 x 450 x 650mm Aluminium Checker Ute Toolbox Trailer Camper Caravan Generator Tool BoxThickness:... -

760 x 500 x 560mm Aluminium Checker Ute Toolbox Trailer Camper Caravan Generator Tool BoxThickness:...

760 x 500 x 560mm Aluminium Checker Ute Toolbox Trailer Camper Caravan Generator Tool BoxThickness:... -

1700 x 550 x 610mm Black Aluminium Checker Ute Truck Tool Box Fridge Slide & Webber BBQ Slide Camper ToolboxThickness:...

1700 x 550 x 610mm Black Aluminium Checker Ute Truck Tool Box Fridge Slide & Webber BBQ Slide Camper ToolboxThickness:... -

2200 x 550 x 550mm Aluminium 3 Lid Slides BBQ Generator Camper ToolboxThickness:...

2200 x 550 x 550mm Aluminium 3 Lid Slides BBQ Generator Camper ToolboxThickness:... -

1400 x 550 x 800mm Black Aluminium Checker Ute Toolbox Webber BBQ & Fridge Slide Camper Caravan Canopy Tool BoxThickness:...

1400 x 550 x 800mm Black Aluminium Checker Ute Toolbox Webber BBQ & Fridge Slide Camper Caravan Canopy Tool BoxThickness:... -

1700 x 550 x 800mm Black Aluminium Checker Ute Toolbox Webber BBQ & Fridge Slide Camper Caravan Canopy Tool BoxThickness:...

1700 x 550 x 800mm Black Aluminium Checker Ute Toolbox Webber BBQ & Fridge Slide Camper Caravan Canopy Tool BoxThickness:... -

2000 x 550 x 800mm Black Aluminium Checker Ute Toolbox Webber BBQ & Fridge Slide Camper Caravan Canopy Tool BoxThickness:...

2000 x 550 x 800mm Black Aluminium Checker Ute Toolbox Webber BBQ & Fridge Slide Camper Caravan Canopy Tool BoxThickness:...

-

-

Cross Deck Gullwing

>

-

1500 x 500 x 500mm Raw Flat Aluminium 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:...

1500 x 500 x 500mm Raw Flat Aluminium 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:... -

2000 x 500 x 500mm Aluminium 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:...

2000 x 500 x 500mm Aluminium 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:... -

1770 x 600 x 500mm Aluminium Checker Sloped Top Gullwing Cross Deck Dual 2 Lid Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

1770 x 600 x 500mm Aluminium Checker Sloped Top Gullwing Cross Deck Dual 2 Lid Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:... -

1770 x 600 x 500mm Aluminium Checker Flat Top Gullwing Cross Deck Dual 2 Lid Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

1770 x 600 x 500mm Aluminium Checker Flat Top Gullwing Cross Deck Dual 2 Lid Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

-

-

Rectangle Ute Toolbox

>

-

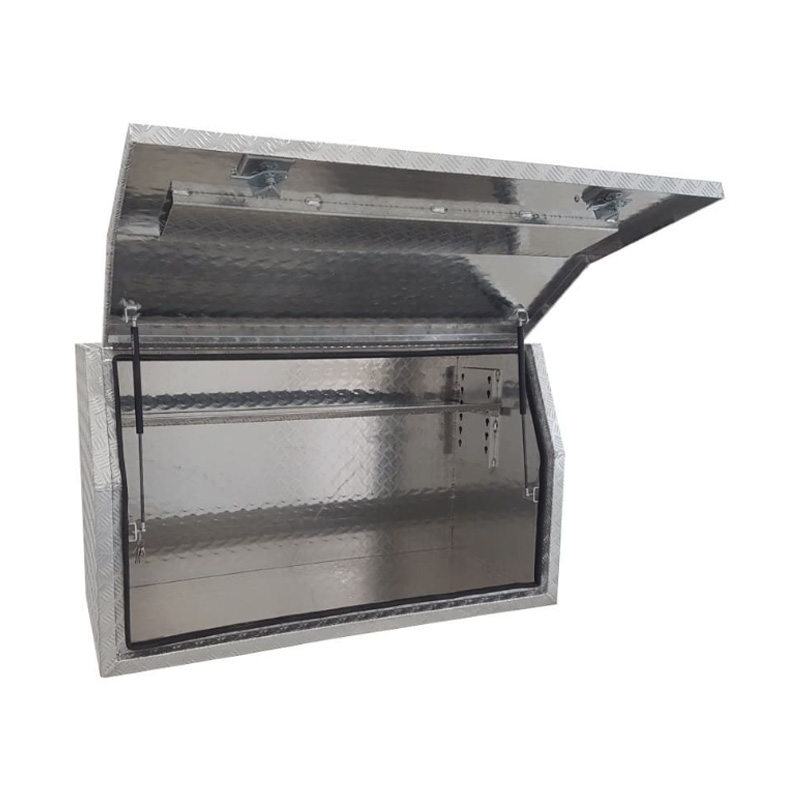

Side Opening Toolboxes

>

-

Half Lid Opening Ute Toolbox

>

-

1200 x 600 x 700mm Aluminium Checker Tool Box Ute Truck Fridge Trailer 3/4 Angle Storage ToolboxThickness:...

1200 x 600 x 700mm Aluminium Checker Tool Box Ute Truck Fridge Trailer 3/4 Angle Storage ToolboxThickness:... -

1400 x 600 x 700mm Aluminium Checker Tool Box Ute Truck Fridge Trailer 3/4 Angle Storage ToolboxThickness:...

1400 x 600 x 700mm Aluminium Checker Tool Box Ute Truck Fridge Trailer 3/4 Angle Storage ToolboxThickness:... -

1400 x 500 x 700mm Aluminium Checker 3/4 Half Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingxThickness:...

1400 x 500 x 700mm Aluminium Checker 3/4 Half Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingxThickness:... -

1700 x 500 x 700mm Aluminium Checker 3/4 Half Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1700 x 500 x 700mm Aluminium Checker 3/4 Half Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1400 x 600 x 820mm Aluminium Checker Full or Half Side Multi Lid Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1400 x 600 x 820mm Aluminium Checker Full or Half Side Multi Lid Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1700 x 600 x 820mm Aluminium Full or Half Side Multi Lid Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1700 x 600 x 820mm Aluminium Full or Half Side Multi Lid Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

900 x 600 x 820mm Aluminium Checker 3/4 Half Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

900 x 600 x 820mm Aluminium Checker 3/4 Half Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1200 x 600 x 820mm Aluminium Checker 3/4 Half Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1200 x 600 x 820mm Aluminium Checker 3/4 Half Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1400 x 600 x 820mm Aluminium 3/4 Half Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1400 x 600 x 820mm Aluminium 3/4 Half Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1700 x 600 x 820mm Aluminium 3/4 Half Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1700 x 600 x 820mm Aluminium 3/4 Half Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

2100 x 600 x 820mm Aluminium 3/4 Half Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

2100 x 600 x 820mm Aluminium 3/4 Half Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

-

-

Half Lid Ute Toolbox With Drawers

>

-

1500 x 600 x 820mm Aluminium Checker 3/4 Half Side Opening 2 Drawer Slide Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1500 x 600 x 820mm Aluminium Checker 3/4 Half Side Opening 2 Drawer Slide Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1400 x 600 x 820mm Aluminium 3/4 Half Side Opening 2 Drawer Slide Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1400 x 600 x 820mm Aluminium 3/4 Half Side Opening 2 Drawer Slide Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1700 x 600 x 820mm Aluminium 3/4 Half Side Opening 3 Drawer Slide Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1700 x 600 x 820mm Aluminium 3/4 Half Side Opening 3 Drawer Slide Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

2100 x 600 x 820mm Aluminium 3/4 Half Side Opening 3 Drawer Slide Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

2100 x 600 x 820mm Aluminium 3/4 Half Side Opening 3 Drawer Slide Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

-

-

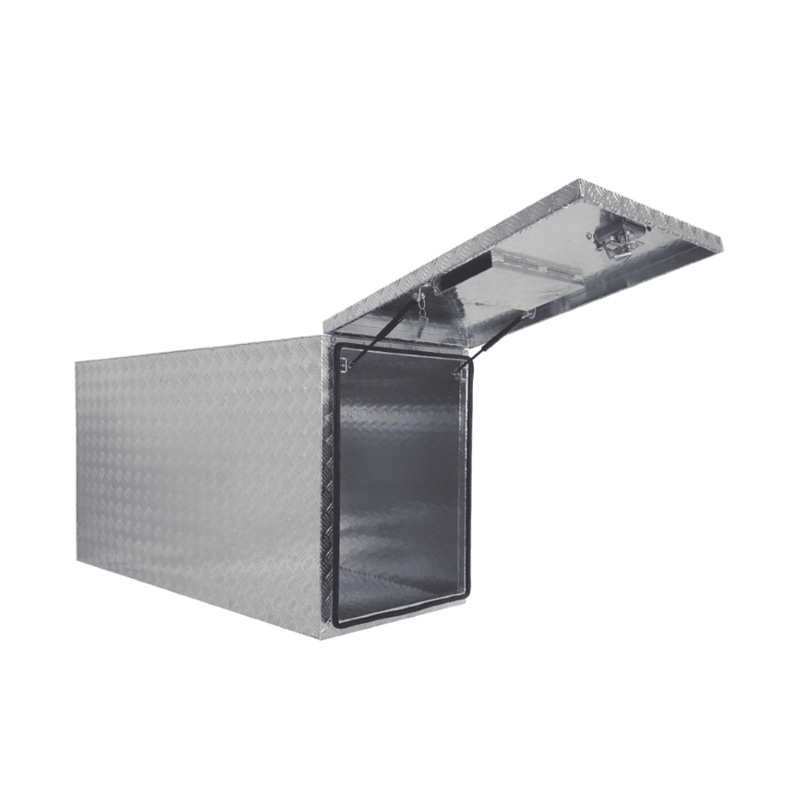

Full Lid Opening Ute Toolbox

>

-

1400 x 500 x 700mm Aluminium Checker Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1400 x 500 x 700mm Aluminium Checker Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1700 x 500 x 700mm Aluminium Checker Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1700 x 500 x 700mm Aluminium Checker Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1400 x 600 x 820mm Aluminium Checker Full or Half Side Multi Lid Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1400 x 600 x 820mm Aluminium Checker Full or Half Side Multi Lid Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1400 x 600 x 820mm Aluminium Checker Full Side Opening Square Edge Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1400 x 600 x 820mm Aluminium Checker Full Side Opening Square Edge Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1700 x 600 x 820mm Aluminium Full or Half Side Multi Lid Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1700 x 600 x 820mm Aluminium Full or Half Side Multi Lid Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1700 x 600 x 820mm Aluminium Checker Full Side Opening Square Edge Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1700 x 600 x 820mm Aluminium Checker Full Side Opening Square Edge Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

900 x 600 x 820mm Aluminium Checker Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

900 x 600 x 820mm Aluminium Checker Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1000 x 530 x 820mm Aluminium Checker Side Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

1000 x 530 x 820mm Aluminium Checker Side Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:... -

1200 x 600 x 820mm Aluminium Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1200 x 600 x 820mm Aluminium Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1400 x 530 x 820mm Aluminium Checker Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1400 x 530 x 820mm Aluminium Checker Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1400 x 600 x 820mm Aluminium Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1400 x 600 x 820mm Aluminium Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1500 x 530 x 820mm Aluminium Checker Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1500 x 530 x 820mm Aluminium Checker Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1600 x 530 x 820mm Aluminium Checker Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1600 x 530 x 820mm Aluminium Checker Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1600 x 600 x 820mm Aluminium Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1600 x 600 x 820mm Aluminium Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1700 x 530 x 820mm Aluminium Checker Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1700 x 530 x 820mm Aluminium Checker Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1700 x 600 x 820mm Aluminium Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1700 x 600 x 820mm Aluminium Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1800 x 530 x 820mm Aluminium Checker Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1800 x 530 x 820mm Aluminium Checker Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1900 x 530 x 820mm Aluminium Checker Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1900 x 530 x 820mm Aluminium Checker Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

2100 x 600 x 820mm Aluminium Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

2100 x 600 x 820mm Aluminium Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1900 x 600 x 820mm Aluminium Full Side Opening Truck Tool Box HIGH Side Trailer Toolbox ShelvingThickness:...

1900 x 600 x 820mm Aluminium Full Side Opening Truck Tool Box HIGH Side Trailer Toolbox ShelvingThickness:...

-

-

Full Lid Ute Toolbox With Drawers

>

-

1400 x 600 x 820mm Aluminium Full Side Opening 2 Drawer Slide Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1400 x 600 x 820mm Aluminium Full Side Opening 2 Drawer Slide Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1400 x 600 x 820mm Aluminium Full Side Opening 4 Drawer Slide Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1400 x 600 x 820mm Aluminium Full Side Opening 4 Drawer Slide Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1700 x 600 x 820mm Aluminium Full Side Opening 2 Drawer Slide Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1700 x 600 x 820mm Aluminium Full Side Opening 2 Drawer Slide Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1700 x 600 x 820mm Aluminium Full Side Opening 4 Drawer Slide Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1700 x 600 x 820mm Aluminium Full Side Opening 4 Drawer Slide Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

-

-

Multi-Lid Ute Toolbox

>

-

1770 x 600 x 500mm Aluminium Checker Sloped Top Gullwing Cross Deck Dual 2 Lid Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

1770 x 600 x 500mm Aluminium Checker Sloped Top Gullwing Cross Deck Dual 2 Lid Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:... -

1770 x 600 x 500mm Aluminium Checker Flat Top Gullwing Cross Deck Dual 2 Lid Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

1770 x 600 x 500mm Aluminium Checker Flat Top Gullwing Cross Deck Dual 2 Lid Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:... -

1400 x 600 x 820mm Aluminium Checker Full or Half Side Multi Lid Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1400 x 600 x 820mm Aluminium Checker Full or Half Side Multi Lid Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1700 x 600 x 820mm Aluminium Full or Half Side Multi Lid Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1700 x 600 x 820mm Aluminium Full or Half Side Multi Lid Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1400 x 600 x 820mm Aluminium Checker Full or Half Side Multi Lid Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1400 x 600 x 820mm Aluminium Checker Full or Half Side Multi Lid Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1700 x 600 x 820mm Aluminium Full or Half Side Multi Lid Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1700 x 600 x 820mm Aluminium Full or Half Side Multi Lid Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

-

-

Half Lid Opening Ute Toolbox

>

-

Truck Toolboxes

>

-

Under Truck Tool Boxes

>

-

600 x 450 x 450mm Aluminium Checker Under Tray Body Tool box Truck Storage ToolboxThickness:...

600 x 450 x 450mm Aluminium Checker Under Tray Body Tool box Truck Storage ToolboxThickness:... -

600 x 450 x 450mm Flat Aluminium Under Tray Body Tool box Truck Storage ToolboxThickness:...

600 x 450 x 450mm Flat Aluminium Under Tray Body Tool box Truck Storage ToolboxThickness:... -

900 x 450 x 450mm Flat Aluminium Under Tray Body Tool box Truck Storage ToolboxThickness:...

900 x 450 x 450mm Flat Aluminium Under Tray Body Tool box Truck Storage ToolboxThickness:... -

1000 x 450 x 450mm Flat Aluminium Under Tray Body Tool box Truck Storage ToolboxThickness:...

1000 x 450 x 450mm Flat Aluminium Under Tray Body Tool box Truck Storage ToolboxThickness:... -

1200 x 450 x 450mm Flat Aluminium Under Tray Body Tool box Truck Storage ToolboxThickness:...

1200 x 450 x 450mm Flat Aluminium Under Tray Body Tool box Truck Storage ToolboxThickness:... -

600 x 500 x 500mm Black Aluminium Under Tray Slide Drawer Body Tool box Truck Storage ToolboxThickness:...

600 x 500 x 500mm Black Aluminium Under Tray Slide Drawer Body Tool box Truck Storage ToolboxThickness:... -

900 x 500 x 500mm Raw Flat Aluminium Under Tray Slide Drawer Body Tool box Truck Storage ToolboxThickness:...

900 x 500 x 500mm Raw Flat Aluminium Under Tray Slide Drawer Body Tool box Truck Storage ToolboxThickness:...

-

- Half Lid Truck Toolbox With Drawers >

-

Full Lid Opening Truck Toolbox

>

-

1400 x 600 x 1200mm Aluminium Full Side Opening Truck Tool Box HIGH Side Trailer Toolbox ShelvingThickness:...

1400 x 600 x 1200mm Aluminium Full Side Opening Truck Tool Box HIGH Side Trailer Toolbox ShelvingThickness:... -

1900 x 600 x 820mm Aluminium Full Side Opening Truck Tool Box HIGH Side Trailer Toolbox Shelving 1968SFD-CPThickness:...

1900 x 600 x 820mm Aluminium Full Side Opening Truck Tool Box HIGH Side Trailer Toolbox Shelving 1968SFD-CPThickness:... -

1900 x 600 x 1200mm Aluminium Checker Full Side Opening Truck Tool Box HIGH Side Trailer Toolbox ShelvingThickness:...

1900 x 600 x 1200mm Aluminium Checker Full Side Opening Truck Tool Box HIGH Side Trailer Toolbox ShelvingThickness:... -

1900 x 600 x 1200mm Checker PRO Full Side Truck Tool Box HIGH Side Toolbox Shelving ReinforcedThickness:...

1900 x 600 x 1200mm Checker PRO Full Side Truck Tool Box HIGH Side Toolbox Shelving ReinforcedThickness:... -

1900 x 600 x 1200mm Aluminium Flat PRO Full Side Truck Tool Box HIGH Side Toolbox Shelving ReinforcedThickness:...

1900 x 600 x 1200mm Aluminium Flat PRO Full Side Truck Tool Box HIGH Side Toolbox Shelving ReinforcedThickness:... -

1900 x 600 x 1200mm Aluminium 4 Drawer Full Side Truck Tool Box HIGH Side Trailer Toolbox ShelvingThickness:...

1900 x 600 x 1200mm Aluminium 4 Drawer Full Side Truck Tool Box HIGH Side Trailer Toolbox ShelvingThickness:... -

1400 x 600 x 820mm Aluminium Checker Full Side Opening Square Edge Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1400 x 600 x 820mm Aluminium Checker Full Side Opening Square Edge Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1700 x 600 x 820mm Aluminium Checker Full Side Opening Square Edge Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1700 x 600 x 820mm Aluminium Checker Full Side Opening Square Edge Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

-

- Full Lid Truck Toolbox With Drawers >

-

Under Truck Tool Boxes

>

- Dog Boxes >

-

Toolbox Canopies

>

-

1770 x 600 x 500mm Aluminium Checker Sloped Top Gullwing Cross Deck Dual 2 Lid Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

1770 x 600 x 500mm Aluminium Checker Sloped Top Gullwing Cross Deck Dual 2 Lid Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:... -

1770 x 600 x 500mm Aluminium Checker Flat Top Gullwing Cross Deck Dual 2 Lid Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

1770 x 600 x 500mm Aluminium Checker Flat Top Gullwing Cross Deck Dual 2 Lid Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:... -

1600 x 700 x 820mm Aluminium Ute Truck Trailer Toolbox Canopy Gullwing 1678-CP-SLDThickness:...

1600 x 700 x 820mm Aluminium Ute Truck Trailer Toolbox Canopy Gullwing 1678-CP-SLDThickness:... -

1770 x 700 x 820mm Aluminium Ute Tool Box Truck Trailer Full Lid Part Canopy ToolboxThickness:...

1770 x 700 x 820mm Aluminium Ute Tool Box Truck Trailer Full Lid Part Canopy ToolboxThickness:... -

1770 x 800 x 820mm Flat Aluminium Ute Tool Box Truck Trailer Full Lid Part Canopy ToolboxThickness:...

1770 x 800 x 820mm Flat Aluminium Ute Tool Box Truck Trailer Full Lid Part Canopy ToolboxThickness:... -

1770 x 1200 x 820mm Aluminium Checker Full Side Part Canopy Tool Box Ute Truck Trailer Toolbox Storage Gullwing ShelvingThickness:...

1770 x 1200 x 820mm Aluminium Checker Full Side Part Canopy Tool Box Ute Truck Trailer Toolbox Storage Gullwing ShelvingThickness:...

-

-

Camper & Trailer Boxes

>

-

Trailer Boxes/Draw bar Boxes

>

-

900 x 400 x 400mm Aluminium Checker Top Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

900 x 400 x 400mm Aluminium Checker Top Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:... -

1220 x 400 x 350mm Aluminium Top Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

1220 x 400 x 350mm Aluminium Top Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:... -

1220 x 500 x 500mm Aluminium Top Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & Canopy 1255Thickness:...

1220 x 500 x 500mm Aluminium Top Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & Canopy 1255Thickness:... -

1500 x 500 x 450mm Aluminium Checker Top Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

1500 x 500 x 450mm Aluminium Checker Top Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:... -

1200 x 600 x 700mm Aluminium Checker Tool Box Ute Truck Fridge Trailer 3/4 Angle Storage ToolboxThickness:...

1200 x 600 x 700mm Aluminium Checker Tool Box Ute Truck Fridge Trailer 3/4 Angle Storage ToolboxThickness:... -

1400 x 600 x 700mm Aluminium Checker Tool Box Ute Truck Fridge Trailer 3/4 Angle Storage ToolboxThickness:...

1400 x 600 x 700mm Aluminium Checker Tool Box Ute Truck Fridge Trailer 3/4 Angle Storage ToolboxThickness:... -

1500 x 400 x 400mm Aluminium Checker 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:...

1500 x 400 x 400mm Aluminium Checker 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:... -

1500 x 500 x 500mm Raw Flat Aluminium 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:...

1500 x 500 x 500mm Raw Flat Aluminium 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:... -

2000 x 500 x 500mm Aluminium 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:...

2000 x 500 x 500mm Aluminium 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:... -

1700 x 550 x 610mm Black Aluminium Checker Ute Truck Tool Box Fridge Slide & Webber BBQ Slide Camper ToolboxThickness:...

1700 x 550 x 610mm Black Aluminium Checker Ute Truck Tool Box Fridge Slide & Webber BBQ Slide Camper ToolboxThickness:... -

2200 x 550 x 550mm Aluminium 3 Lid Slides BBQ Generator Camper ToolboxThickness:...

2200 x 550 x 550mm Aluminium 3 Lid Slides BBQ Generator Camper ToolboxThickness:... -

1400 x 550 x 800mm Black Aluminium Checker Ute Toolbox Webber BBQ & Fridge Slide Camper Caravan Canopy Tool BoxThickness:...

1400 x 550 x 800mm Black Aluminium Checker Ute Toolbox Webber BBQ & Fridge Slide Camper Caravan Canopy Tool BoxThickness:... -

1700 x 550 x 800mm Black Aluminium Checker Ute Toolbox Webber BBQ & Fridge Slide Camper Caravan Canopy Tool BoxThickness:...

1700 x 550 x 800mm Black Aluminium Checker Ute Toolbox Webber BBQ & Fridge Slide Camper Caravan Canopy Tool BoxThickness:... -

2000 x 550 x 800mm Black Aluminium Checker Ute Toolbox Webber BBQ & Fridge Slide Camper Caravan Canopy Tool BoxThickness:...

2000 x 550 x 800mm Black Aluminium Checker Ute Toolbox Webber BBQ & Fridge Slide Camper Caravan Canopy Tool BoxThickness:... -

1770 x 600 x 500mm Aluminium Checker Sloped Top Gullwing Cross Deck Dual 2 Lid Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

1770 x 600 x 500mm Aluminium Checker Sloped Top Gullwing Cross Deck Dual 2 Lid Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:... -

1770 x 600 x 500mm Aluminium Checker Flat Top Gullwing Cross Deck Dual 2 Lid Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

1770 x 600 x 500mm Aluminium Checker Flat Top Gullwing Cross Deck Dual 2 Lid Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:... -

860 x 460 x 460mm Aluminium Checker Toolbox Trailer Draw Bar Storage DrawBar Tool BoxThickness:...

860 x 460 x 460mm Aluminium Checker Toolbox Trailer Draw Bar Storage DrawBar Tool BoxThickness:... -

1200 x 500 x 500mm Aluminium Toolbox Trailer Draw Bar Storage DrawBar Tool BoxThickness:...

1200 x 500 x 500mm Aluminium Toolbox Trailer Draw Bar Storage DrawBar Tool BoxThickness:... -

1400 x 580 x 820mm Aluminium Checker Full Side Center Box Caravan Ute Tool Box Truck Cab Trailer ToolboxThickness:...

1400 x 580 x 820mm Aluminium Checker Full Side Center Box Caravan Ute Tool Box Truck Cab Trailer ToolboxThickness:... -

1700 x 580 x 820mm Aluminium Checker Full Side Center Box Caravan Ute Tool Box Truck Cab Trailer ToolboxThickness:...

1700 x 580 x 820mm Aluminium Checker Full Side Center Box Caravan Ute Tool Box Truck Cab Trailer ToolboxThickness:...

-

-

Caravan Boxes

>

-

1500 x 400 x 400mm Aluminium Checker 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:...

1500 x 400 x 400mm Aluminium Checker 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:... -

1500 x 500 x 500mm Raw Flat Aluminium 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:...

1500 x 500 x 500mm Raw Flat Aluminium 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:... -

2000 x 500 x 500mm Aluminium 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:...

2000 x 500 x 500mm Aluminium 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:... -

1700 x 550 x 610mm Black Aluminium Checker Ute Truck Tool Box Fridge Slide & Webber BBQ Slide Camper ToolboxThickness:...

1700 x 550 x 610mm Black Aluminium Checker Ute Truck Tool Box Fridge Slide & Webber BBQ Slide Camper ToolboxThickness:... -

2200 x 550 x 550mm Aluminium 3 Lid Slides BBQ Generator Camper ToolboxThickness:...

2200 x 550 x 550mm Aluminium 3 Lid Slides BBQ Generator Camper ToolboxThickness:... -

1400 x 550 x 800mm Black Aluminium Checker Ute Toolbox Webber BBQ & Fridge Slide Camper Caravan Canopy Tool BoxThickness:...

1400 x 550 x 800mm Black Aluminium Checker Ute Toolbox Webber BBQ & Fridge Slide Camper Caravan Canopy Tool BoxThickness:... -

1700 x 550 x 800mm Black Aluminium Checker Ute Toolbox Webber BBQ & Fridge Slide Camper Caravan Canopy Tool BoxThickness:...

1700 x 550 x 800mm Black Aluminium Checker Ute Toolbox Webber BBQ & Fridge Slide Camper Caravan Canopy Tool BoxThickness:... -

2000 x 550 x 800mm Black Aluminium Checker Ute Toolbox Webber BBQ & Fridge Slide Camper Caravan Canopy Tool BoxThickness:...

2000 x 550 x 800mm Black Aluminium Checker Ute Toolbox Webber BBQ & Fridge Slide Camper Caravan Canopy Tool BoxThickness:... -

1600 x 700 x 820mm Aluminium Ute Truck Trailer Toolbox Canopy Gullwing 1678-CP-SLDThickness:...

1600 x 700 x 820mm Aluminium Ute Truck Trailer Toolbox Canopy Gullwing 1678-CP-SLDThickness:...

-

-

Generator Boxes

>

-

610 x 330 x 540mm Aluminium Checker Ute Toolbox Trailer Camper Caravan Generator Tool Box for Honda 2kvaThickness:...

610 x 330 x 540mm Aluminium Checker Ute Toolbox Trailer Camper Caravan Generator Tool Box for Honda 2kvaThickness:... -

700 x 450 x 650mm Aluminium Checker Ute Toolbox Trailer Camper Caravan Generator Tool BoxThickness:...

700 x 450 x 650mm Aluminium Checker Ute Toolbox Trailer Camper Caravan Generator Tool BoxThickness:... -

760 x 500 x 560mm Aluminium Checker Ute Toolbox Trailer Camper Caravan Generator Tool BoxThickness:...

760 x 500 x 560mm Aluminium Checker Ute Toolbox Trailer Camper Caravan Generator Tool BoxThickness:...

-

-

Trailer Boxes/Draw bar Boxes

>

-

Under Tray Toolboxes

>

- Accessories

-

Trailers Accessories

>

- Trailer Jockey Wheel >

-

Trailer Coupler

>

-

AU 2/3 Hole Quick Release 50 mm Non Braked CouplerSuits 50mm...

AU 2/3 Hole Quick Release 50 mm Non Braked CouplerSuits 50mm... -

AU 50 mm Mechanical Brake CouplerSuits 50mm...

AU 50 mm Mechanical Brake CouplerSuits 50mm... -

AU Electric Coupling 50 mm Towball 3.5T RatedSuits 50mm...

AU Electric Coupling 50 mm Towball 3.5T RatedSuits 50mm... -

NZ 1-7/8 Non Braked CouplerSuits 45mm...

NZ 1-7/8 Non Braked CouplerSuits 45mm... -

NZ 1-7/8 Mechanical Brake CouplerSuits 45mm...

NZ 1-7/8 Mechanical Brake CouplerSuits 45mm... -

NZ Electric Coupling 50 mm Towball 3.5T RatedSuits 50mm...

NZ Electric Coupling 50 mm Towball 3.5T RatedSuits 50mm...

-

-

Trailer Spring

>

-

Slipper to Eye Spring, 6×45×5

Slipper to Eye Spring, 6×45×5 -

Slipper to Eye Spring, 6×45×6

Slipper to Eye Spring, 6×45×6 -

Slipper to Eye Spring, 6×45×7

Slipper to Eye Spring, 6×45×7 -

Eye to Eye Spring, 8×45×5

Eye to Eye Spring, 8×45×5 -

Eye to Eye Spring, 8×45×7

Eye to Eye Spring, 8×45×7 -

Eye to Eye Spring 6×45×5

Eye to Eye Spring 6×45×5 -

Leaf Rocker Roller Spring, 6×60×7

Leaf Rocker Roller Spring, 6×60×7 -

Leaf Rocker Roller Spring, 6×60×9

Leaf Rocker Roller Spring, 6×60×9 -

Boat trailer Slipper to Eye Spring 6×45×5

Boat trailer Slipper to Eye Spring 6×45×5 -

Boat trailer Slipper to Eye Spring 6×45×7

Boat trailer Slipper to Eye Spring 6×45×7

-

- Trailer Axle >

- Trailer Brake >

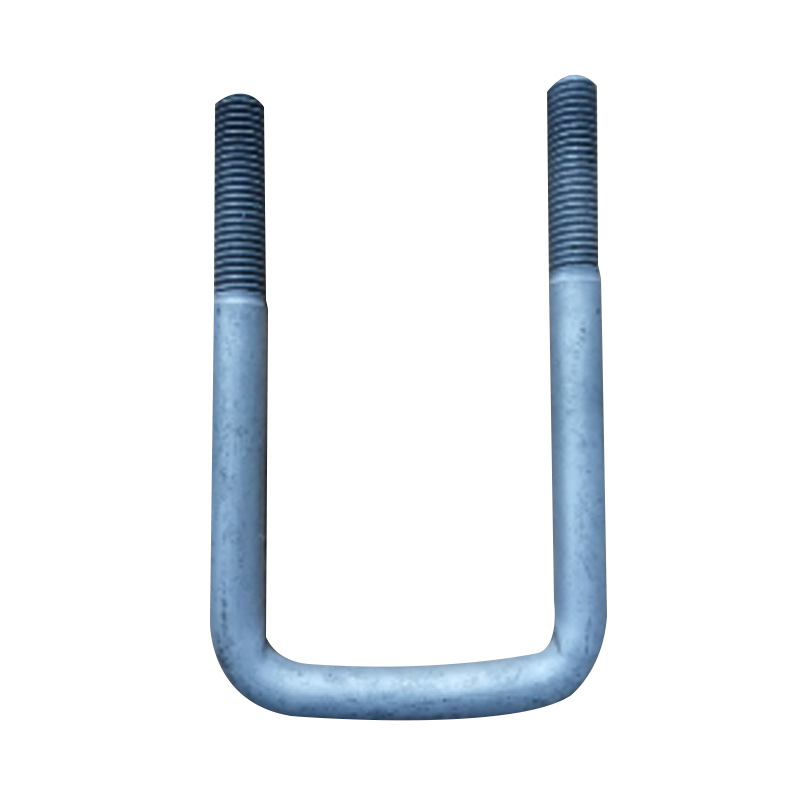

- Trailer U Bolt >

- Trailer Wheel >

-

Trailer Mudguard

>

-

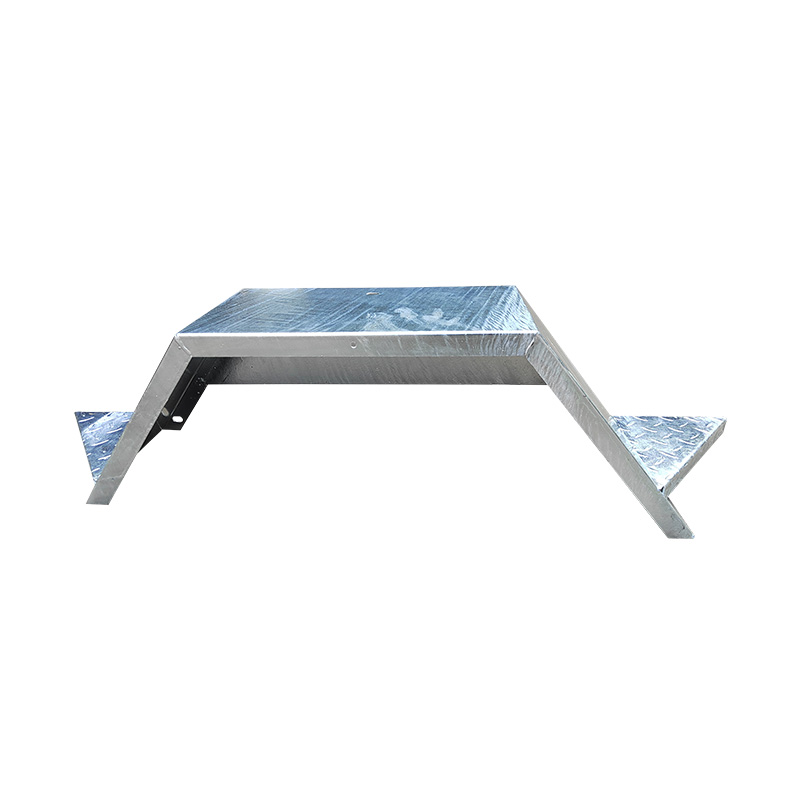

13" Single Axle Galvanized Trailer MudguardThis 13-in...

13" Single Axle Galvanized Trailer MudguardThis 13-in... -

14" Single Axle Galvanized Trailer MudguardBuilt for ...

14" Single Axle Galvanized Trailer MudguardBuilt for ... -

14" Single Axle Galvanized Trailer Mudguard with Side StepThis 14-in...

14" Single Axle Galvanized Trailer Mudguard with Side StepThis 14-in... -

14" Single Axle Round Galvanized Trailer MudguardCrafted wi...

14" Single Axle Round Galvanized Trailer MudguardCrafted wi... -

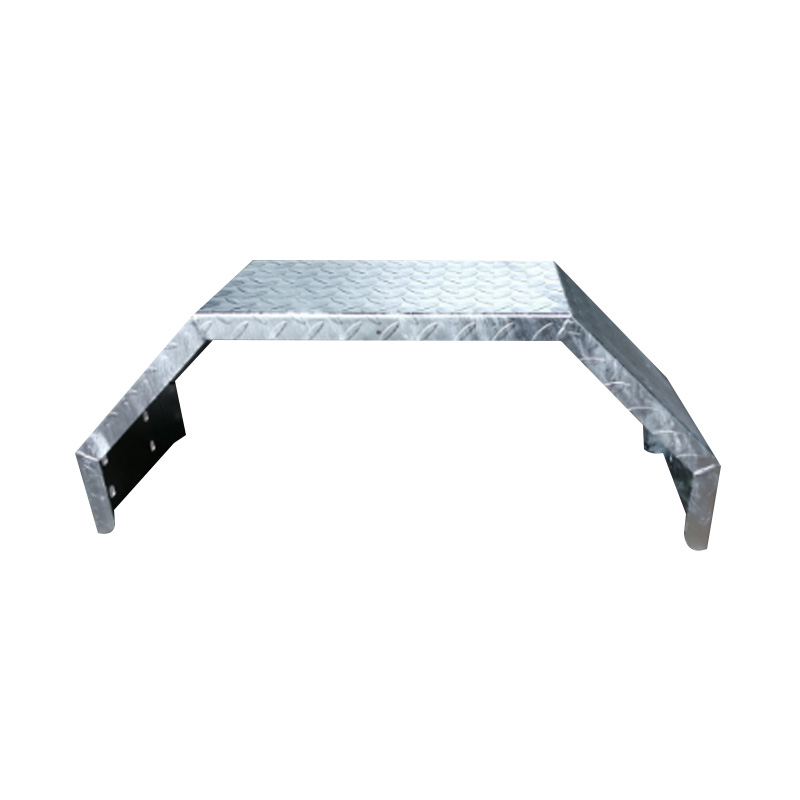

14" Tandem Galvanized Trailer MudguardEngineered...

14" Tandem Galvanized Trailer MudguardEngineered... -

14" Tandem Aluminum Trailer MudguardThis 14-in...

14" Tandem Aluminum Trailer MudguardThis 14-in...

-

-

Trailer Light

>

-

LED Tail light M/Volt 107 x 99 mm 12/24V without Number Plate LightTrailer li...

LED Tail light M/Volt 107 x 99 mm 12/24V without Number Plate LightTrailer li... -

LED Tail light M/Volt 107 x 99 mm 12/24V with Number Plate LightTrailer li...

LED Tail light M/Volt 107 x 99 mm 12/24V with Number Plate LightTrailer li... -

White- LED SIDE Marker 60×38 mm M/Volt ClearTrailer si...

White- LED SIDE Marker 60×38 mm M/Volt ClearTrailer si... -

Yellow-LED SIDE Marker 59×35 mm M/Volt ClearTrailer si...

Yellow-LED SIDE Marker 59×35 mm M/Volt ClearTrailer si... -

Yellow & Red-LED SIDE 59×35 mm Marker M/Volt ClearTrailer si...

Yellow & Red-LED SIDE 59×35 mm Marker M/Volt ClearTrailer si... -

80×35 mm LED Number Plate LightTrailer nu...

80×35 mm LED Number Plate LightTrailer nu... -

70×30 mm Reflector Stick On AmberReflectors...

70×30 mm Reflector Stick On AmberReflectors... -

70×30 mm Reflector Stick On RedReflectors...

70×30 mm Reflector Stick On RedReflectors... -

70×30 mm Reflector Stick On ClearReflectors...

70×30 mm Reflector Stick On ClearReflectors...

-

- Trailer Cage >

- Trailer Canvas Cover >

-

Trailer Drawbar Toolbox

>

-

Side Open Trailer Drawbar Aluminum Toolbox with Fridge Slideavaiable f...

Side Open Trailer Drawbar Aluminum Toolbox with Fridge Slideavaiable f... -

Top Opening Trailer Drawbar Aluminum Toolboxavaiable f...

Top Opening Trailer Drawbar Aluminum Toolboxavaiable f... -

Checker Top Opening Trailer Drawbar Aluminum Toolboxavaiable f...

Checker Top Opening Trailer Drawbar Aluminum Toolboxavaiable f... -

3/4 Angle Toolbox Trailer Drawbar Aluminum Toolboxavaiable f...

3/4 Angle Toolbox Trailer Drawbar Aluminum Toolboxavaiable f... -

Aluminum Trailer Tongue Storage Toolbox with Lockavaiable f...

Aluminum Trailer Tongue Storage Toolbox with Lockavaiable f... -

Checker 3 Lid Ute Toolbox Trailer Drawbar Aluminum Toolboxavaiable f...

Checker 3 Lid Ute Toolbox Trailer Drawbar Aluminum Toolboxavaiable f... -

Aluminium 3 Lid Slides Trailer Drawbar Toolbox with Fridge Slideavaiable f...

Aluminium 3 Lid Slides Trailer Drawbar Toolbox with Fridge Slideavaiable f... -

Black Aluminium Ute Toolbox Fridge Slide Trailer Drawbar Toolboxavaiable f...

Black Aluminium Ute Toolbox Fridge Slide Trailer Drawbar Toolboxavaiable f... -

Black Trailer Drawbar Aluminum Toolbox with Fridge Slideavaiable f...

Black Trailer Drawbar Aluminum Toolbox with Fridge Slideavaiable f... -

Gullwing 2 Lid Trailer Drawbar Aluminum Toolboxavaiable f...

Gullwing 2 Lid Trailer Drawbar Aluminum Toolboxavaiable f... -

Checker Flat Top Dual 2 Lid Trailer Drawbar Aluminum Toolboxavaiable f...

Checker Flat Top Dual 2 Lid Trailer Drawbar Aluminum Toolboxavaiable f... -

Full Side Opening Door Trailer Drawbar Aluminum Toolboxavaiable f...

Full Side Opening Door Trailer Drawbar Aluminum Toolboxavaiable f...

-

- Trailer Mower Box >

- Trailer H Bar >

- Trailer Spare Wheel Holder >

-

Toolbox Accessories

>

- Toolbox Mounting Kit >

-

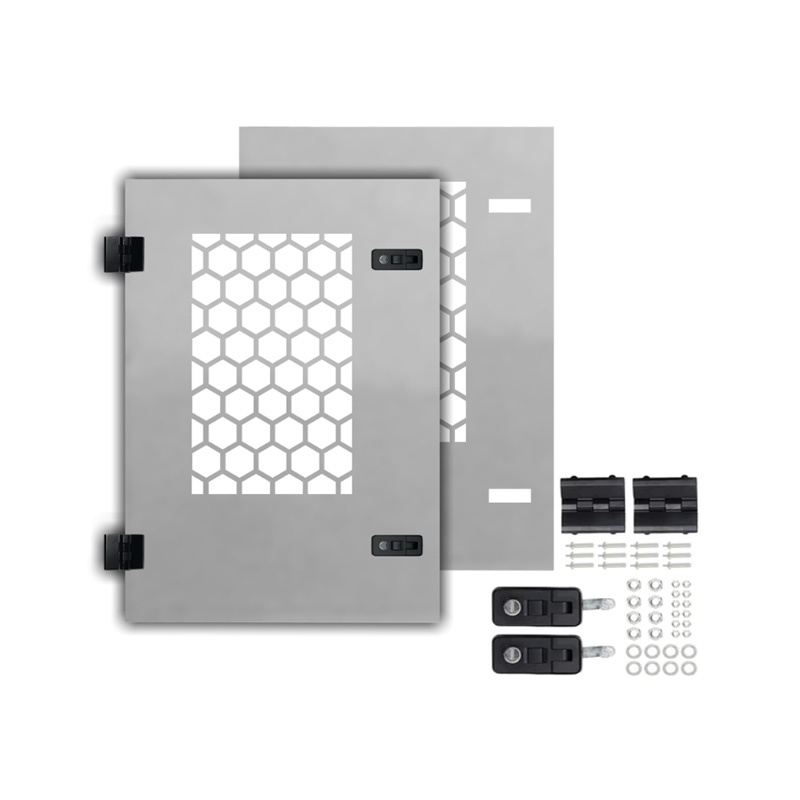

Toolbox Locks

>

-

Stainless Steel T-Lock STUD MountMaterial: ...

Stainless Steel T-Lock STUD MountMaterial: ... -

12V Recessed Folding Padlock Friendly Whale Tail Handle ACT-WTLOCKKey lockin...

12V Recessed Folding Padlock Friendly Whale Tail Handle ACT-WTLOCKKey lockin... -

Whale Tail T-Lock Padlockable Whale Tail HandleKey lockin...

Whale Tail T-Lock Padlockable Whale Tail HandleKey lockin... -

Black Whale Tail T-Lock Padlockable Whale Tail HandleKey lockin...

Black Whale Tail T-Lock Padlockable Whale Tail HandleKey lockin... -

Chome & Black Whale Tail T-Lock Padlockable Whale Tail HandleKey lockin...

Chome & Black Whale Tail T-Lock Padlockable Whale Tail HandleKey lockin... -

White Whale Tail T-Lock Padlockable Whale Tail HandleKey lockin...

White Whale Tail T-Lock Padlockable Whale Tail HandleKey lockin...

-

-

Toolbox Drawer Unites

>

-

600 x 430 x 450mm Black Aluminium 3 Drawer Unit for Ute Truck Tool box Canopy Caravan Tool BoxThickness:...

600 x 430 x 450mm Black Aluminium 3 Drawer Unit for Ute Truck Tool box Canopy Caravan Tool BoxThickness:... -

600 x 430 x 620mm Black Aluminium 4 Drawer Unit for Ute Truck Tool box Canopy Caravan Tool BoxThickness:...

600 x 430 x 620mm Black Aluminium 4 Drawer Unit for Ute Truck Tool box Canopy Caravan Tool BoxThickness:... -

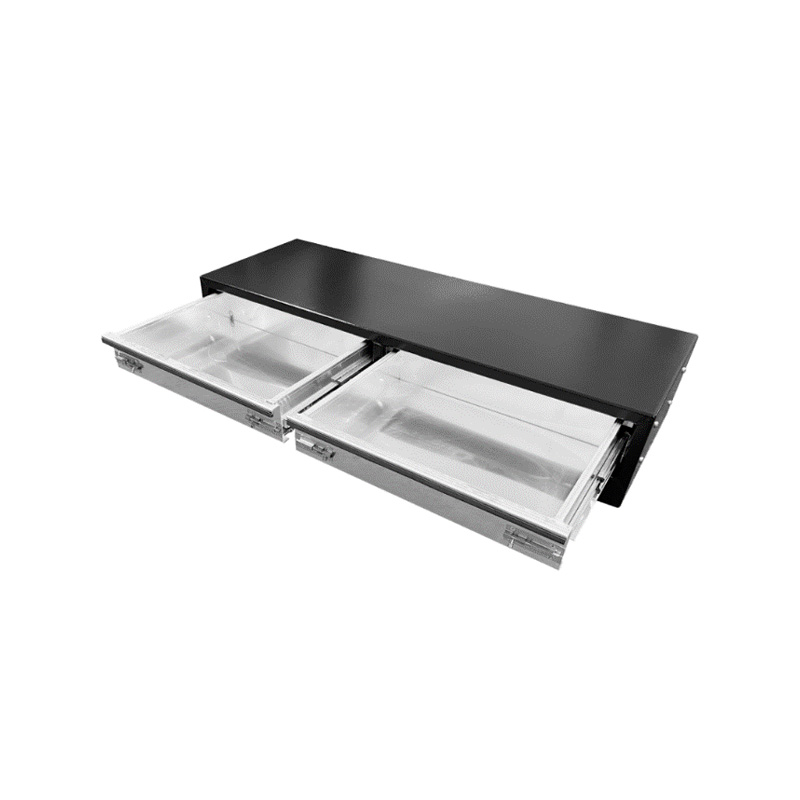

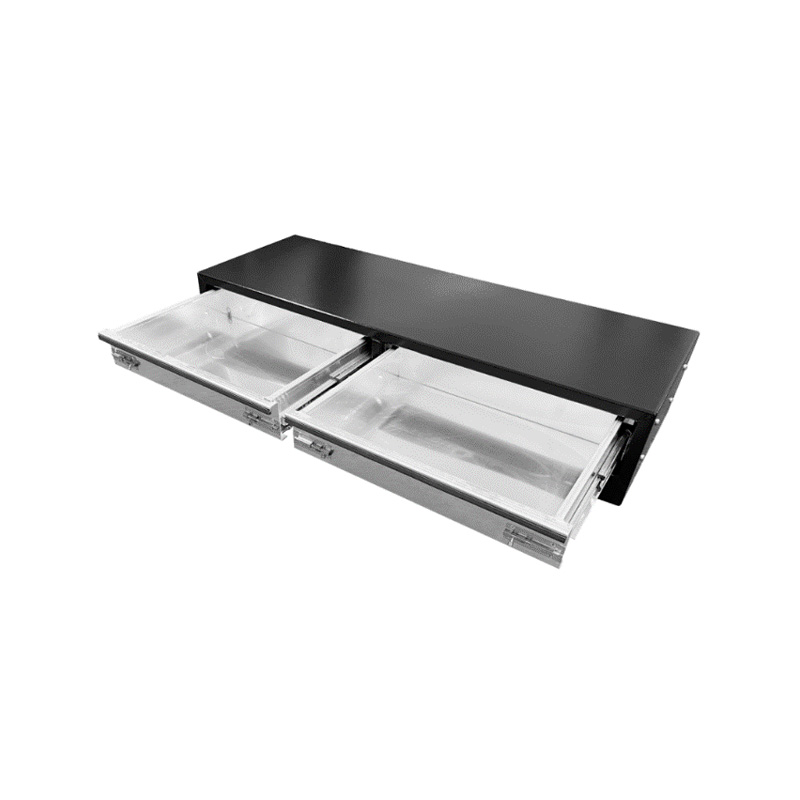

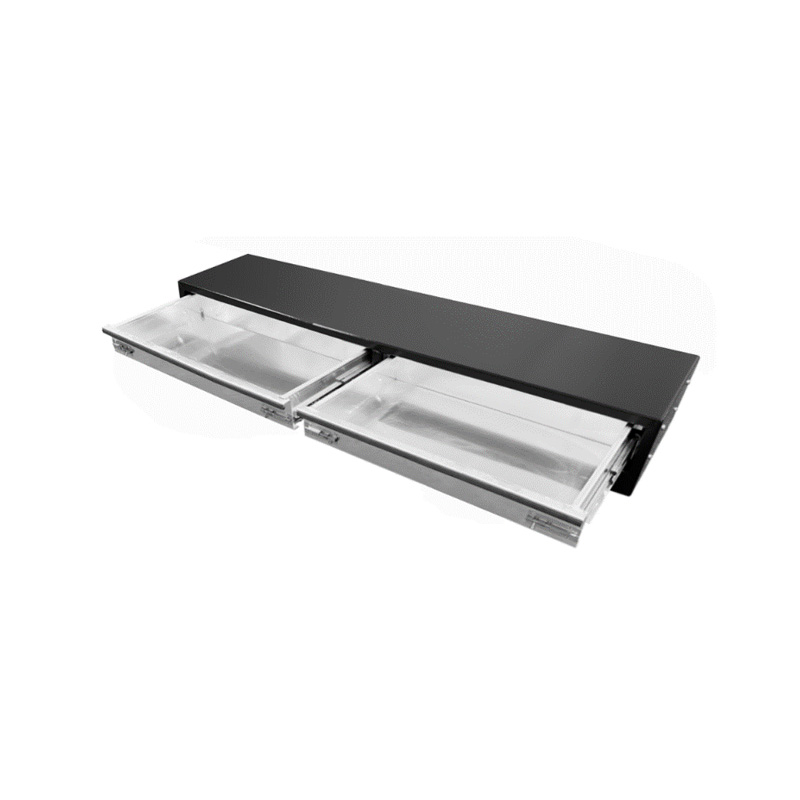

1020 x 440 x 230mm Black Aluminium 2 Drawer Unit for Ute Truck Tool box Canopy Caravan ToolboxThickness:...

1020 x 440 x 230mm Black Aluminium 2 Drawer Unit for Ute Truck Tool box Canopy Caravan ToolboxThickness:... -

1220 x 440 x 230mm Black Aluminium 2 Drawer Unit for Ute Truck Tool box Canopy Caravan ToolboxThickness:...

1220 x 440 x 230mm Black Aluminium 2 Drawer Unit for Ute Truck Tool box Canopy Caravan ToolboxThickness:... -

520 x 440 x 230mm Black Aluminium 2 Drawer Unit for Ute Truck Tool box Canopy Caravan ToolboxThickness:...

520 x 440 x 230mm Black Aluminium 2 Drawer Unit for Ute Truck Tool box Canopy Caravan ToolboxThickness:... -

1920 x 440 x 230mm Black Aluminium 2 Drawer Unit for Ute Truck Tool box Canopy Caravan Tool BoxThickness:...

1920 x 440 x 230mm Black Aluminium 2 Drawer Unit for Ute Truck Tool box Canopy Caravan Tool BoxThickness:... -

1400 x 600 x 380mm 1 Drawer Unit for Ute Truck Tool box Canopy Caravan ToolboxThickness:...

1400 x 600 x 380mm 1 Drawer Unit for Ute Truck Tool box Canopy Caravan ToolboxThickness:... -

1400 x 600 x 380mm 2 Drawer Unit for Ute Truck Tool box Canopy Caravan ToolboxThickness:...

1400 x 600 x 380mm 2 Drawer Unit for Ute Truck Tool box Canopy Caravan ToolboxThickness:... -

1700 x 600 x 380mm 3 Drawer Unit for Ute Truck Tool box Canopy Caravan ToolboxThickness:...

1700 x 600 x 380mm 3 Drawer Unit for Ute Truck Tool box Canopy Caravan ToolboxThickness:... -

1900 x 600 x 380mm 3 Drawer Unit for Ute Truck Tool box Canopy Caravan ToolboxThickness:...

1900 x 600 x 380mm 3 Drawer Unit for Ute Truck Tool box Canopy Caravan ToolboxThickness:... -

1.4m Aluminium Ute Tool box Under Tray Toolbox Trundle Roller Tray Slide Out Drawer Toolbox Benchtop LidThickness:...

1.4m Aluminium Ute Tool box Under Tray Toolbox Trundle Roller Tray Slide Out Drawer Toolbox Benchtop LidThickness:... -

1.6m Aluminium Ute Tool box Under Tray Toolbox Trundle Roller Tray Slide Out Drawer Toolbox Benchtop LidThickness:...

1.6m Aluminium Ute Tool box Under Tray Toolbox Trundle Roller Tray Slide Out Drawer Toolbox Benchtop LidThickness:... -

1.7m Aluminium Ute Tool box Under Tray Toolbox Trundle Roller Tray Slide Out Drawer Toolbox Benchtop LidThickness:...

1.7m Aluminium Ute Tool box Under Tray Toolbox Trundle Roller Tray Slide Out Drawer Toolbox Benchtop LidThickness:...

-

-

Toolbox Shelves

>

-

0.9m Shelf - For Aluminium Storage Toolbox Tool BoxThickness:...

0.9m Shelf - For Aluminium Storage Toolbox Tool BoxThickness:... -

1.2m Shelf - For Aluminium Storage Toolbox Tool BoxThickness:...

1.2m Shelf - For Aluminium Storage Toolbox Tool BoxThickness:... -

1.4m Shelf - For Aluminium Storage Toolbox Tool BoxThickness:...

1.4m Shelf - For Aluminium Storage Toolbox Tool BoxThickness:... -

1.5m Shelf - For Aluminium Storage Toolbox Tool BoxThickness:...

1.5m Shelf - For Aluminium Storage Toolbox Tool BoxThickness:... -

1.6m Shelf - For Aluminium Storage Toolbox Tool BoxThickness:...

1.6m Shelf - For Aluminium Storage Toolbox Tool BoxThickness:... -

1.7m Shelf - For Aluminium Storage Toolbox Tool BoxThickness:...

1.7m Shelf - For Aluminium Storage Toolbox Tool BoxThickness:... -

1.8m Shelf - For Aluminium Storage Toolbox Tool BoxThickness:...

1.8m Shelf - For Aluminium Storage Toolbox Tool BoxThickness:... -

1.9m Shelf - For Aluminium Storage Toolbox Tool BoxThickness:...

1.9m Shelf - For Aluminium Storage Toolbox Tool BoxThickness:... -

1.94m Shelf - For Aluminium Storage Toolbox Tool BoxThickness:...

1.94m Shelf - For Aluminium Storage Toolbox Tool BoxThickness:... -

2.1m Shelf - For Aluminium Storage Toolbox Tool BoxThickness:...

2.1m Shelf - For Aluminium Storage Toolbox Tool BoxThickness:...

-

-

Gas Strut

>

-

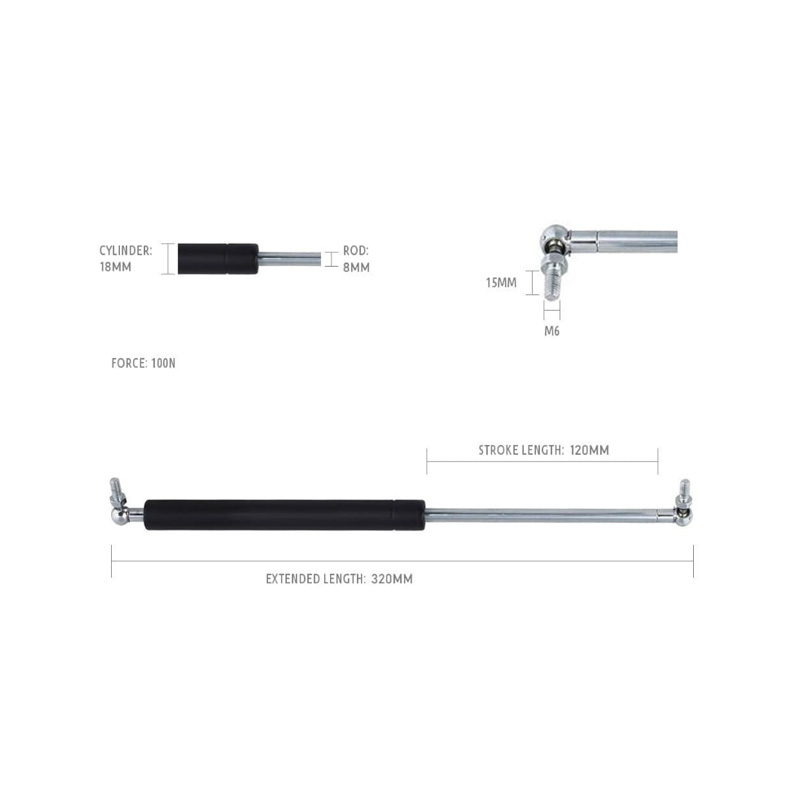

Gas Strut 120-320/100N GS120-320-100NExtended L...

Gas Strut 120-320/100N GS120-320-100NExtended L... -

Gas Strut 120-320/180N GS120-320-180NExtended L...

Gas Strut 120-320/180N GS120-320-180NExtended L... -

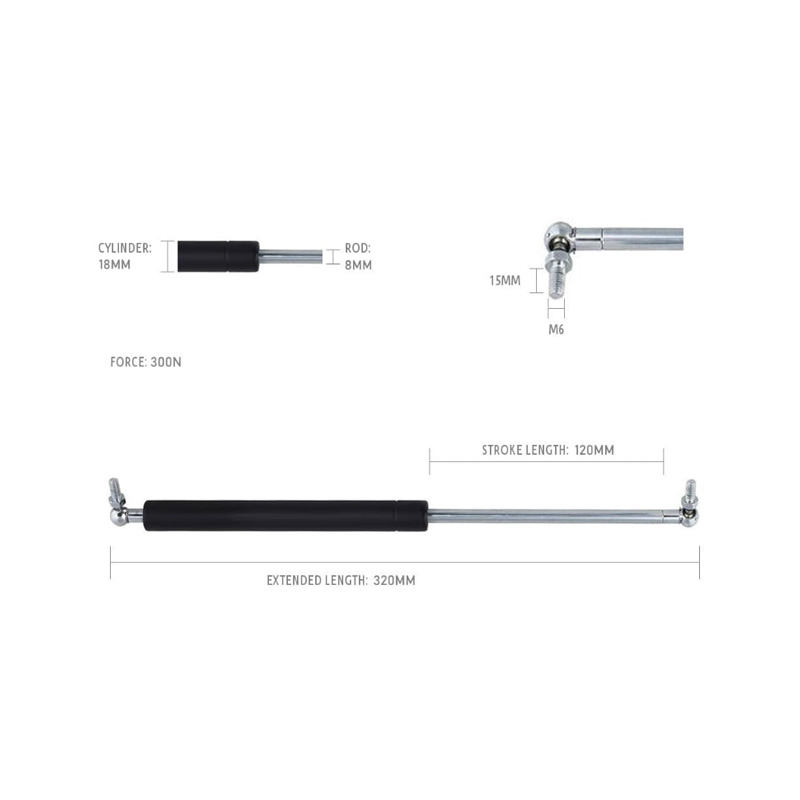

Gas Strut 120-320/300N GS120-320-300NExtended L...

Gas Strut 120-320/300N GS120-320-300NExtended L... -

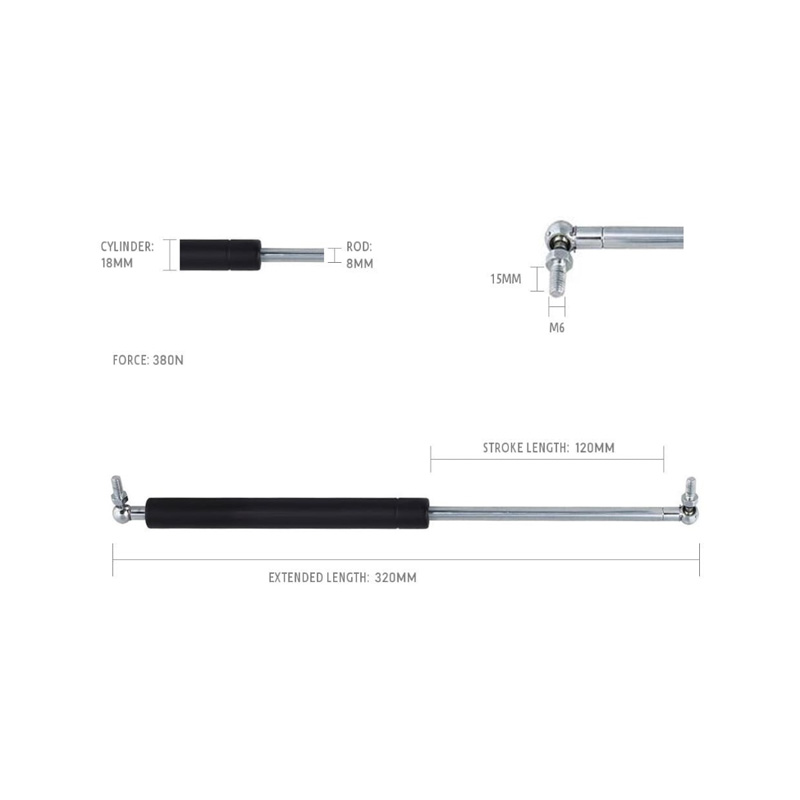

Gas Strut 120-320/380N GS120-320-380NExtended L...

Gas Strut 120-320/380N GS120-320-380NExtended L... -

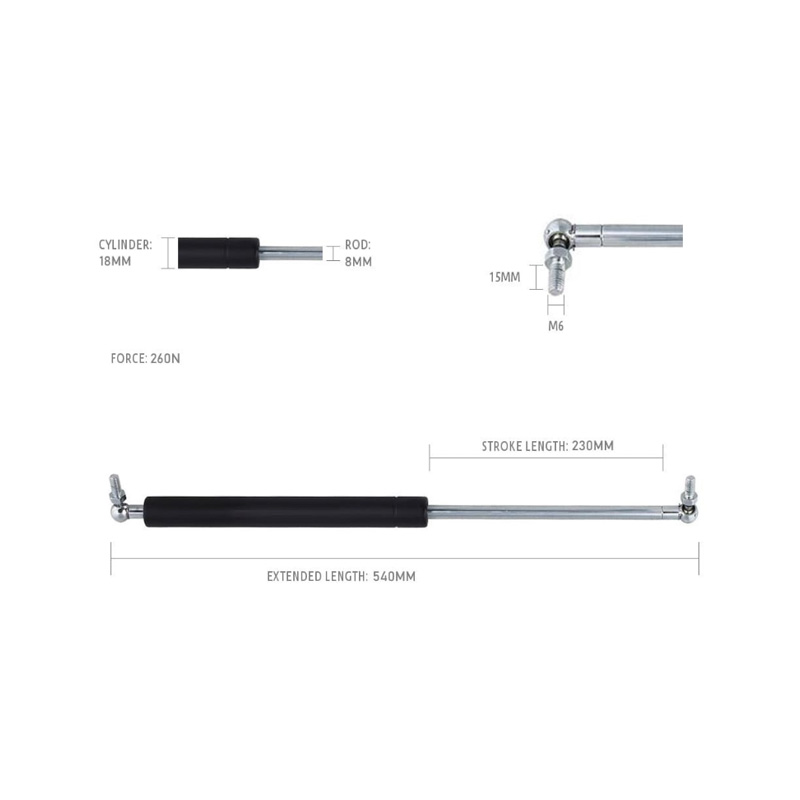

Gas Strut 230-540/260N GS230-540-260NExtended L...

Gas Strut 230-540/260N GS230-540-260NExtended L... -

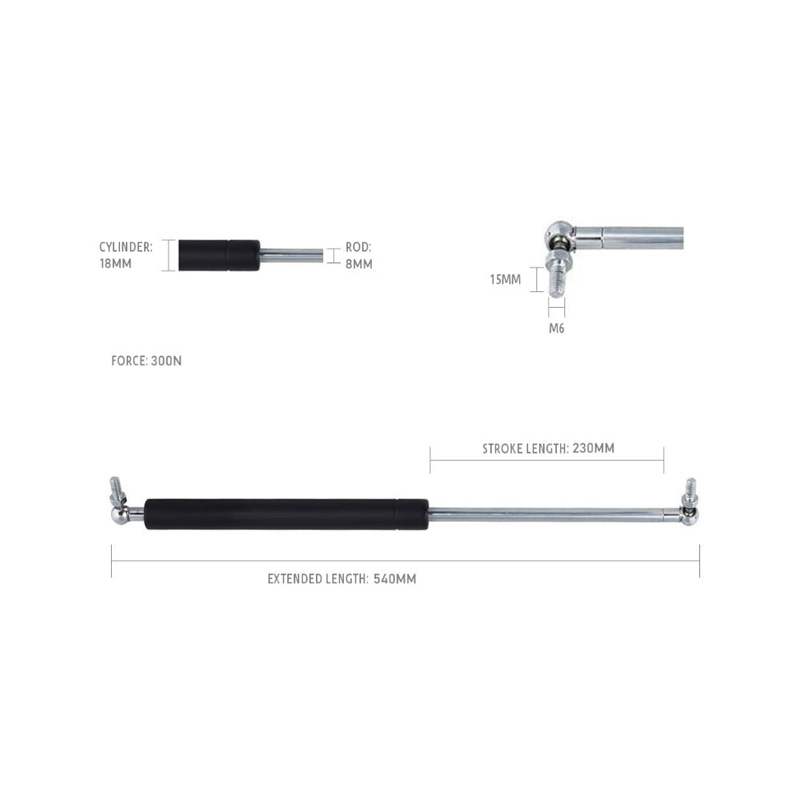

Gas Strut 230-540/300N GS230-540-300NExtended L...

Gas Strut 230-540/300N GS230-540-300NExtended L... -

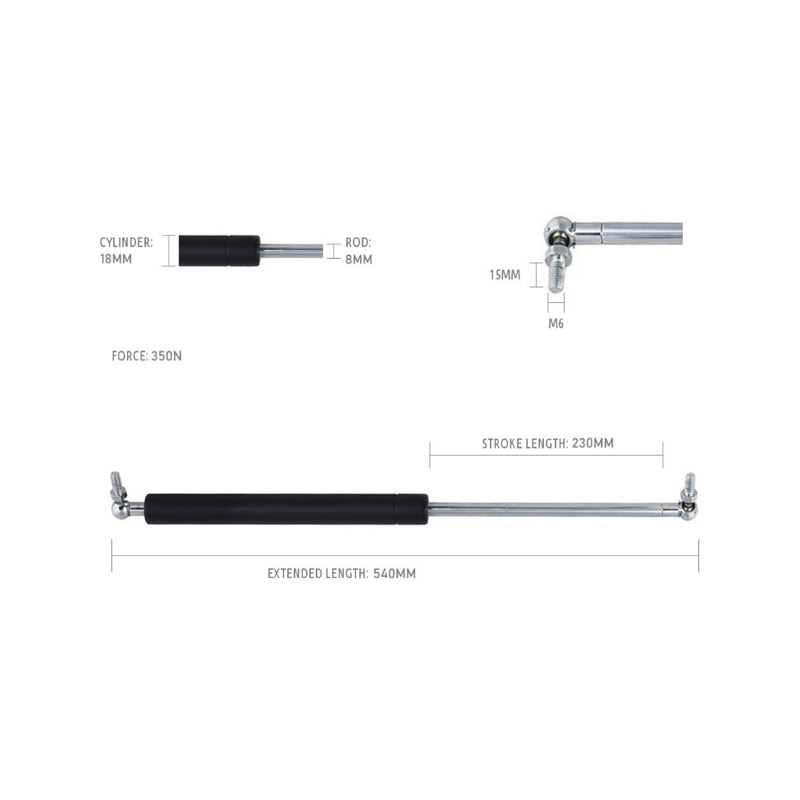

Gas Strut 230-540/350N GS230-540-350NExtended L...

Gas Strut 230-540/350N GS230-540-350NExtended L... -

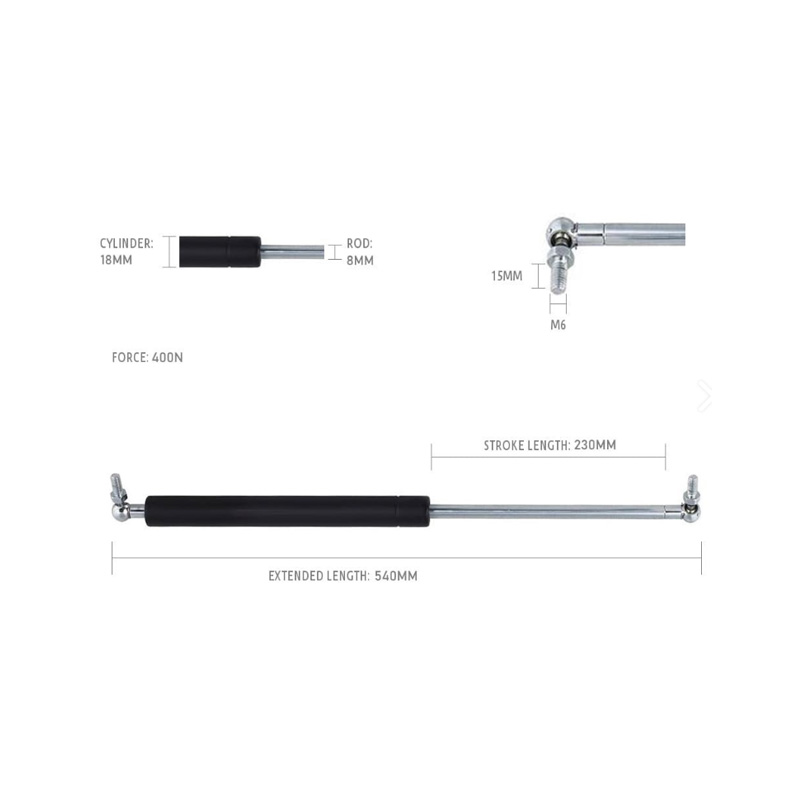

Gas Strut 230-540/400N GS230-540-400NExtended L...

Gas Strut 230-540/400N GS230-540-400NExtended L...

-

- Ladder Rack >

- Canopy Ladder >

- Toolbox Cargo Cage >

- Toolbox Rear Gate >

-

Fuel Gas Tool Holder

>

-

600 x 230 x 290mm Aluminium Tool Storage Handle Holder Heavy Duty ToteThickness:...

600 x 230 x 290mm Aluminium Tool Storage Handle Holder Heavy Duty ToteThickness:... -

320 x 320 x 320mm Aluminium Checker Camping Camper 4x4 Ute Truck Trailer Gas Bottle HolderSize Lengt...

320 x 320 x 320mm Aluminium Checker Camping Camper 4x4 Ute Truck Trailer Gas Bottle HolderSize Lengt... -

450 x 230 x 300mm Aluminium Checker Camping Camper 4x4 Ute Truck Acetylene Oxy Gas Bottle Holder with DividerThickness:...

450 x 230 x 300mm Aluminium Checker Camping Camper 4x4 Ute Truck Acetylene Oxy Gas Bottle Holder with DividerThickness:... -

450 x 230 x 380mm Aluminium Camping 4x4 Ute Truck Acetylene Oxy Gas Bottle Holder with DividerThickness:...

450 x 230 x 380mm Aluminium Camping 4x4 Ute Truck Acetylene Oxy Gas Bottle Holder with DividerThickness:... -

450 x 230 x 300mm Aluminium Checker Camping Camper 4x4 Ute Truck Acetylene Oxy Gas Bottle HolderThickness:...

450 x 230 x 300mm Aluminium Checker Camping Camper 4x4 Ute Truck Acetylene Oxy Gas Bottle HolderThickness:... -

450 x 230 x 380mm Aluminium Camping 4x4 Ute Truck Acetylene Oxy Gas Bottle HolderSize Lengt...

450 x 230 x 380mm Aluminium Camping 4x4 Ute Truck Acetylene Oxy Gas Bottle HolderSize Lengt... -

400 x 220 x 500mm Checker Aluminium Ute Camping Camper Jerry Can Bottle Holder Pad lockable Tool BoxThickness:...

400 x 220 x 500mm Checker Aluminium Ute Camping Camper Jerry Can Bottle Holder Pad lockable Tool BoxThickness:... -

335 x 285 x 400mm 4.5kg Aluminium Gas Bottle HolderThickness:...

335 x 285 x 400mm 4.5kg Aluminium Gas Bottle HolderThickness:... -

361 x 196 x 303mm Flat Aluminium Ute Camping Camper Jerry Can Bottle Holder Tool BoxThickness:...

361 x 196 x 303mm Flat Aluminium Ute Camping Camper Jerry Can Bottle Holder Tool BoxThickness:...

-

- Jack off Legs >

-

Trailers Accessories

>

- About

- News

- Contact

Web Menu

- Home

- TRAILERS

- TOOLBOXES

- ACCESSORIES

- About

- News

- Contact Us

Product Search

What Are the Disadvantages of Aluminum Toolboxes with Drawers?

Aluminum toolboxes with drawers have several drawbacks that can affect long-term performance and user satisfaction. One major disadvantage is cost. Aluminum toolboxes often cost more than comparable steel or plastic models due to material and manufacturing expenses. For users on a tight budget, this can be a significant consideration.

Although aluminum is strong, it is softer than steel. In heavy-duty environments or during transport, the toolbox may dent or bend if subjected to impact or heavy loads. While dents may not always affect functionality, they can reduce the overall durability and aesthetic appearance.

Aluminum toolboxes can scratch easily, especially on the surface finish. Frequent handling, tool movement, and exposure to rough materials can cause visible scratches. Over time, scratches can affect the toolbox's appearance and may bring about surface corrosion in harsh environments if the protective coating is damaged.

Another drawback is drawer mechanism wear. Drawers with ball-bearing slides require proper maintenance and alignment. In dusty or dirty environments, debris can affect smooth operation, causing drawers to stick or become misaligned.

Aluminum toolboxes may have lower security than heavier steel options. Although many models include locks, the lighter material can be easier to pry or deform, which may be a concern in high-risk settings.

Aluminum Toolboxes with Drawers: What Can We Know?

Understanding aluminum toolboxes with drawers requires awareness of their design, materials, and typical use scenarios. The following points summarize key knowledge:

Material characteristics

Aluminum is lightweight, corrosion-resistant, and relatively strong. These features make aluminum toolboxes ideal for mobile use, such as in vehicles or job sites.

Weight advantage

Compared to steel toolboxes, aluminum models are easier to move and install. This is especially useful for mobile mechanics or technicians who need to transport tools frequently.

Corrosion resistance

Aluminum naturally forms a protective oxide layer, which helps resist rust. This is beneficial in humid or marine environments, where steel may corrode more easily.

Drawer organization

Toolboxes with drawers allow for organized storage of wrenches, sockets, screwdrivers, and other tools. Drawers help improve workflow by making tools easier to find and access.

Customization and modularity

Many aluminum toolboxes support modular drawer layouts, allowing users to customize storage based on tool size and type. Some models include removable drawer liners or foam inserts.

Locking and security

Many models include lockable drawers or a central lock. However, security effectiveness depends on the locking mechanism and overall construction.

Maintenance needs

Regular cleaning and lubrication of drawer slides can prevent sticking. Avoid using harsh chemicals that may damage surface coatings.

Aluminum Toolboxes with Drawers: Selection and Maintenance

How to Choose the Right Aluminum Toolbox

Selecting the right aluminum toolbox with drawers depends on storage needs, mobility, and environment. For workshop use, larger toolboxes with multiple drawer levels provide ample storage and better organization. For mobile use, such as in service vehicles, a compact toolbox with secure locking and strong mounting points is often preferred.

Consider the drawer configuration and weight capacity. Deeper drawers are suitable for larger tools, while shallow drawers work well for smaller hand tools and accessories. Check the drawer slide type—ball-bearing slides provide smoother operation and better load support than basic roller slides. Additionally, consider the toolbox's finish and protective coatings, especially if used in harsh or outdoor environments. Powder-coated surfaces can resist scratches and corrosion better than plain aluminum.

Maintenance Practices for Long-Term Use

Maintaining an aluminum toolbox with drawers is essential to ensure smooth operation and longevity. Regularly clean the toolbox to remove dust, debris, and tool residue. For drawer slides, use a light lubricant to reduce friction and prevent sticking. In dusty environments, consider using drawer liners to protect the slides and tools.

Inspect the toolbox periodically for dents, loose screws, or damaged locks. If the surface is scratched, applying a protective coating or touch-up paint can help prevent corrosion in exposed areas. For mobile toolboxes, ensure mounting brackets and fasteners remain secure to prevent movement during transport.

If drawers become misaligned, adjust the slides or consult the manufacturer's instructions. Avoid overloading drawers beyond their weight capacity, as this can damage slides and affect stability. Proper organization and weight distribution also help maintain balance and reduce strain on the toolbox structure.

Post a comment

- GET A QUOTE

- PRODUCTS

- TRAILERS

- TOOLBOXES

- ACCESSORIES

- CONTACT US

-

-

+86-0579-82795522

+86-0579-82795522 -

+86-13362901332(Jack)

+86-13362901332(Jack)

-

-

No. 1533 Huaxi Road, Jinhua City, Zhejiang Province, China

No. 1533 Huaxi Road, Jinhua City, Zhejiang Province, China

-

- MOBILE SITE

English

English  Español

Español  русский

русский