- Home

-

Trailers

- Box Trailers >

-

Flat Top/Flat Bed Trailers

>

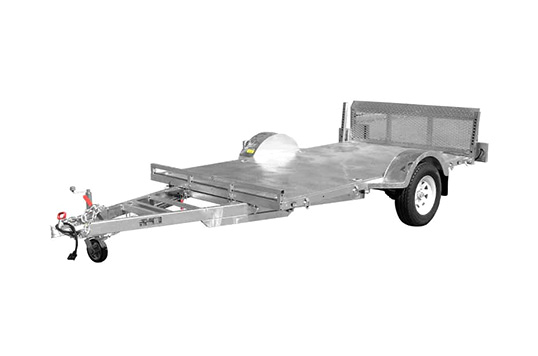

- Single Axle Flatbed Trailers >

-

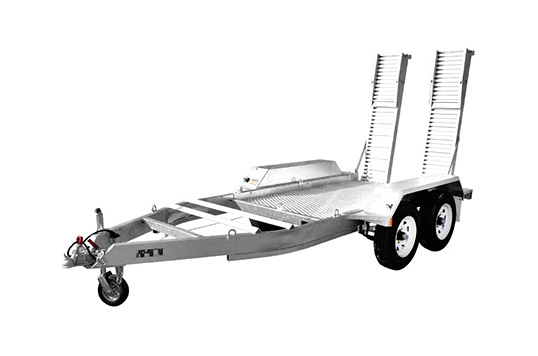

Tandem Axle Flatbed Trailers

>

-

8×5ft ATM 1990KG Flat Top /Flat Bed TrailerTrail...

8×5ft ATM 1990KG Flat Top /Flat Bed TrailerTrail... -

10×6.3ft ATM 2800KG Flat Top /Flat Bed Tandem TrailerTrail...

10×6.3ft ATM 2800KG Flat Top /Flat Bed Tandem TrailerTrail... -

10×6ft ATM 3500KG Flat Top /Flat Bed Hydraulic Tipper TrailerTrail...

10×6ft ATM 3500KG Flat Top /Flat Bed Hydraulic Tipper TrailerTrail... -

12×7ft ATM 3500KG Flat Top /Flat Bed Tandem TrailerTrail...

12×7ft ATM 3500KG Flat Top /Flat Bed Tandem TrailerTrail... -

14×7ft 3500KG ATM Flat Bed Tandem TrailerTrail...

14×7ft 3500KG ATM Flat Bed Tandem TrailerTrail... -

12×7ft ATM 3500KG Tandem Flatbed Hydraulic Tipper TrailerTrail...

12×7ft ATM 3500KG Tandem Flatbed Hydraulic Tipper TrailerTrail...

-

- Tri Axle Flatbed Trailers >

- Hydraulic Tippers >

- Cattle/ Livestock Trailers >

-

Boat, Kayak & Jet Ski Trailers

>

-

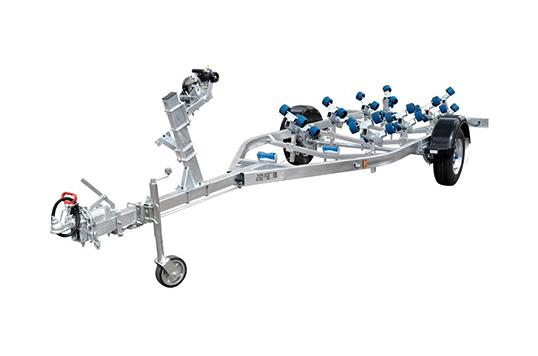

Single Axle Rollers Boat Trailer

>

-

4100 Series 750KG ATM Single Axle Rollers Boat TrailerTrail...

4100 Series 750KG ATM Single Axle Rollers Boat TrailerTrail... -

4500 Series 750KG ATM Single Axle Rollers Boat TrailerTrail...

4500 Series 750KG ATM Single Axle Rollers Boat TrailerTrail... -

4900 Series 1200KG ATM Single Axle Rollers Boat TrailerTrail...

4900 Series 1200KG ATM Single Axle Rollers Boat TrailerTrail... -

5700 Series 1500KG ATM Single Axle Rollers Boat TrailerTrail...

5700 Series 1500KG ATM Single Axle Rollers Boat TrailerTrail... -

6300 Series 1500KG ATM Single Axle Rollers Boat TrailerTrail...

6300 Series 1500KG ATM Single Axle Rollers Boat TrailerTrail...

-

- Single Axle Skid Boat Trailer >

- Tandem Axle Rollers Boat Trailer >

- Kayak & Canoe Trailer >

-

Single Axle Rollers Boat Trailer

>

- Motorcycles, ATV & Buggy Trailers >

- Car & Plant Trailers >

- Gardening & Mowing Trailers >

-

Builders/Tradesman Trailers

>

-

Single Axle Fully Enclosed & Luggage Trailer

>

-

6×4ft Small Tradesman/ Builders TrailerTrail...

6×4ft Small Tradesman/ Builders TrailerTrail... -

7×4ft Tradesman/ Builders TrailerTrail...

7×4ft Tradesman/ Builders TrailerTrail... -

7×5ft Tradesman/ Builders Trailer with Aluminium CanopyTrail...

7×5ft Tradesman/ Builders Trailer with Aluminium CanopyTrail... -

8×5ft Durable Tradesman/ Builders TrailerTrail...

8×5ft Durable Tradesman/ Builders TrailerTrail... -

8×6ft ATM 750KG Tradesman/ Builders TrailerTrail...

8×6ft ATM 750KG Tradesman/ Builders TrailerTrail... -

7×5ft Heavy Duty Tradesman/ Builders TrailerTrail...

7×5ft Heavy Duty Tradesman/ Builders TrailerTrail... -

8×5ft Heavy Duty ATM 1400KG Tradesman/ Builders TrailerTrail...

8×5ft Heavy Duty ATM 1400KG Tradesman/ Builders TrailerTrail... -

8×6ft Heavy Duty Enclosed Tradesman/ Builders TrailerTrail...

8×6ft Heavy Duty Enclosed Tradesman/ Builders TrailerTrail...

-

-

Tandem Axle Builders/Tradesman Trailer

>

-

8×5ft Dual Axle Builders/Tradesman TrailerTrail...

8×5ft Dual Axle Builders/Tradesman TrailerTrail... -

10×5ft Tandem Builders/Tradesman TrailerTrail...

10×5ft Tandem Builders/Tradesman TrailerTrail... -

10×6ft Tandem Builders/Tradesman TrailerTrail...

10×6ft Tandem Builders/Tradesman TrailerTrail... -

8×5ft Tandem Axle Tradesman/ Builders TrailerTrail...

8×5ft Tandem Axle Tradesman/ Builders TrailerTrail... -

10×5ft Tandem Tradesman/ Builders TrailerTrail...

10×5ft Tandem Tradesman/ Builders TrailerTrail... -

10×6ft Tandem Tradesman/ Builders Trailer with Aluminium CanopyTrail...

10×6ft Tandem Tradesman/ Builders Trailer with Aluminium CanopyTrail...

-

-

Single Axle Fully Enclosed & Luggage Trailer

>

- Enclosed/Luggage Trailers >

-

Toolboxes

-

Under Tray Toolboxes

>

-

Ute Under Tray Toolboxes

>

-

580 x 230 x 400mm Aluminium Checker Ute Toolbox Truck Storage Under Body Tray Storage Strap Tool BoxThickness:...

580 x 230 x 400mm Aluminium Checker Ute Toolbox Truck Storage Under Body Tray Storage Strap Tool BoxThickness:... -

600 x 200 x 400mm Aluminium 20L Ute Camping Under Tray Body Box Storage Water TankThickness:...

600 x 200 x 400mm Aluminium 20L Ute Camping Under Tray Body Box Storage Water TankThickness:... -

600 x 230 x 400mm Aluminium Pair Ute Toolbox Truck Storage Under Body Tray Storage Strap Tool Box Off Road TapperThickness:...

600 x 230 x 400mm Aluminium Pair Ute Toolbox Truck Storage Under Body Tray Storage Strap Tool Box Off Road TapperThickness:... -

600 x 230 x 400mm Aluminium Set Pair Ute Toolbox Truck Storage Under Body Tray Storage Strap Tool Box Off Road TapperThickness:...

600 x 230 x 400mm Aluminium Set Pair Ute Toolbox Truck Storage Under Body Tray Storage Strap Tool Box Off Road TapperThickness:... -

750 x 230 x 400mm Aluminium SET PAIR Ute Toolbox Truck Storage Under Body Tray Storage Strap Tool Box Off Road TapperThickness:...

750 x 230 x 400mm Aluminium SET PAIR Ute Toolbox Truck Storage Under Body Tray Storage Strap Tool Box Off Road TapperThickness:... -

750 x 230 x 400mm Aluminium SET PAIR Ute Toolbox Truck Storage Under Body Tray Storage Strap Tool Box Off Road TapperThickness:...

750 x 230 x 400mm Aluminium SET PAIR Ute Toolbox Truck Storage Under Body Tray Storage Strap Tool Box Off Road TapperThickness:... -

700 x 260 x 400mm (LIMITED EDITION) Under Tray Toolbox TapperedThickness:...

700 x 260 x 400mm (LIMITED EDITION) Under Tray Toolbox TapperedThickness:... -

940 x 230 x 400mm Aluminium SET PAIR Ute Toolbox Truck Storage Under Body Tray Storage Strap Tool Box Off Road TapperThickness:...

940 x 230 x 400mm Aluminium SET PAIR Ute Toolbox Truck Storage Under Body Tray Storage Strap Tool Box Off Road TapperThickness:... -

940 x 230 x 400mm Aluminium SET PAIR Ute Toolbox Truck Storage Under Body Tray Storage Strap Tool Box Off Road TapperThickness:...

940 x 230 x 400mm Aluminium SET PAIR Ute Toolbox Truck Storage Under Body Tray Storage Strap Tool Box Off Road TapperThickness:... -

900 x 260 x 400mm (LIMITED EDITION) Under Tray Toolbox TapperedThickness:...

900 x 260 x 400mm (LIMITED EDITION) Under Tray Toolbox TapperedThickness:...

-

-

Truck Under Tray Boxes

>

-

600 x 450 x 450mm Aluminium Checker Under Tray Body Tool box Truck Storage ToolboxThickness:...

600 x 450 x 450mm Aluminium Checker Under Tray Body Tool box Truck Storage ToolboxThickness:... -

600 x 450 x 450mm Flat Aluminium Under Tray Body Tool box Truck Storage ToolboxThickness:...

600 x 450 x 450mm Flat Aluminium Under Tray Body Tool box Truck Storage ToolboxThickness:... -

900 x 450 x 450mm Flat Aluminium Under Tray Body Tool box Truck Storage ToolboxThickness:...

900 x 450 x 450mm Flat Aluminium Under Tray Body Tool box Truck Storage ToolboxThickness:... -

1000 x 450 x 450mm Flat Aluminium Under Tray Body Tool box Truck Storage ToolboxThickness:...

1000 x 450 x 450mm Flat Aluminium Under Tray Body Tool box Truck Storage ToolboxThickness:... -

1200 x 450 x 450mm Flat Aluminium Under Tray Body Tool box Truck Storage ToolboxThickness:...

1200 x 450 x 450mm Flat Aluminium Under Tray Body Tool box Truck Storage ToolboxThickness:... -

600 x 500 x 500mm Black Aluminium Under Tray Slide Drawer Body Tool box Truck Storage ToolboxThickness:...

600 x 500 x 500mm Black Aluminium Under Tray Slide Drawer Body Tool box Truck Storage ToolboxThickness:... -

900 x 500 x 500mm Raw Flat Aluminium Under Tray Slide Drawer Body Tool box Truck Storage ToolboxThickness:...

900 x 500 x 500mm Raw Flat Aluminium Under Tray Slide Drawer Body Tool box Truck Storage ToolboxThickness:... -

1200 x 500 x 500mm Black Aluminium Under Tray Slide Drawer Body Tool box Truck Storage ToolboxThickness:...

1200 x 500 x 500mm Black Aluminium Under Tray Slide Drawer Body Tool box Truck Storage ToolboxThickness:...

-

-

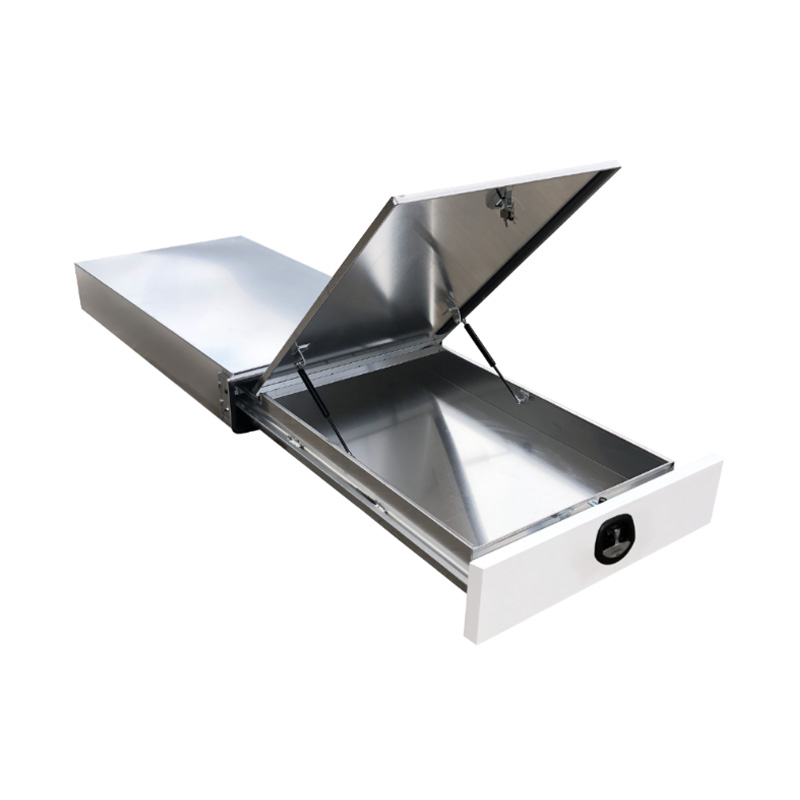

Trundle-Trays

>

-

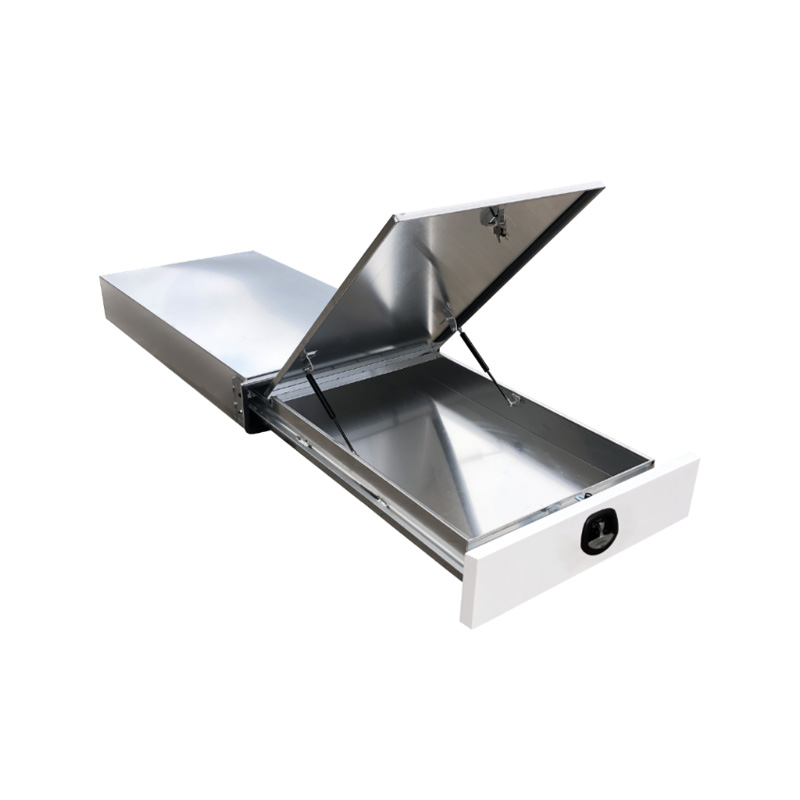

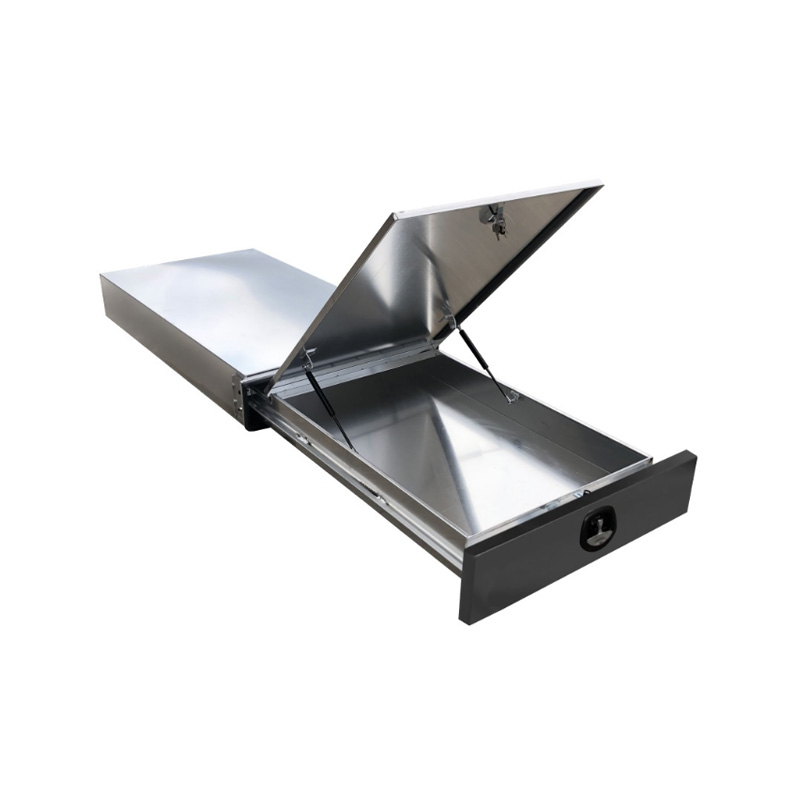

1.4m Aluminium Ute Tool box Under Tray Toolbox Trundle Roller Tray Slide Out Drawer Toolbox Benchtop LidThickness:...

1.4m Aluminium Ute Tool box Under Tray Toolbox Trundle Roller Tray Slide Out Drawer Toolbox Benchtop LidThickness:... -

1.6m Aluminium Ute Tool box Under Tray Toolbox Trundle Roller Tray Slide Out Drawer Toolbox Benchtop LidThickness:...

1.6m Aluminium Ute Tool box Under Tray Toolbox Trundle Roller Tray Slide Out Drawer Toolbox Benchtop LidThickness:... -

1.7m Aluminium Ute Tool box Under Tray Toolbox Trundle Roller Tray Slide Out Drawer Toolbox Benchtop LidThickness:...

1.7m Aluminium Ute Tool box Under Tray Toolbox Trundle Roller Tray Slide Out Drawer Toolbox Benchtop LidThickness:...

-

- Under Tray Water Tanks >

-

Ute Under Tray Toolboxes

>

-

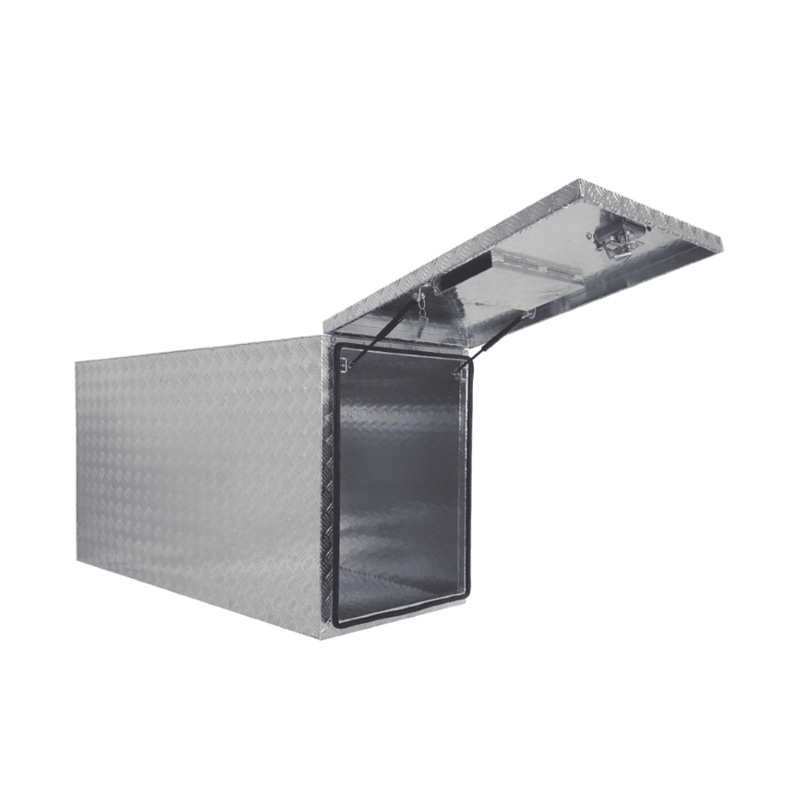

Top Opening Toolboxes

>

-

Rectangle Ute Toolbox

>

-

900 x 400 x 400mm Aluminium Checker Top Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

900 x 400 x 400mm Aluminium Checker Top Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:... -

1220 x 400 x 350mm Aluminium Top Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

1220 x 400 x 350mm Aluminium Top Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:... -

1220 x 500 x 500mm Aluminium Top Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & Canopy 1255Thickness:...

1220 x 500 x 500mm Aluminium Top Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & Canopy 1255Thickness:... -

1500 x 500 x 450mm Aluminium Checker Top Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

1500 x 500 x 450mm Aluminium Checker Top Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:... -

1200 x 600 x 500mm Aluminium Top Chest Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & Canopy(Chest Style)Thickness:...

1200 x 600 x 500mm Aluminium Top Chest Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & Canopy(Chest Style)Thickness:... -

1400 x 600 x 500mm Aluminium Top Chest Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

1400 x 600 x 500mm Aluminium Top Chest Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:... -

1700 x 600 x 500mm Aluminium Top Chest Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

1700 x 600 x 500mm Aluminium Top Chest Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:... -

1200 x 600 x 700mm Aluminium Checker Tool Box Ute Truck Fridge Trailer 3/4 Angle Storage ToolboxThickness:...

1200 x 600 x 700mm Aluminium Checker Tool Box Ute Truck Fridge Trailer 3/4 Angle Storage ToolboxThickness:... -

1400 x 600 x 700mm Aluminium Checker Tool Box Ute Truck Fridge Trailer 3/4 Angle Storage ToolboxThickness:...

1400 x 600 x 700mm Aluminium Checker Tool Box Ute Truck Fridge Trailer 3/4 Angle Storage ToolboxThickness:... -

1500 x 400 x 400mm Aluminium Checker 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:...

1500 x 400 x 400mm Aluminium Checker 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:... -

1500 x 500 x 500mm Raw Flat Aluminium 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:...

1500 x 500 x 500mm Raw Flat Aluminium 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:... -

2000 x 500 x 500mm Aluminium 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:...

2000 x 500 x 500mm Aluminium 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:...

-

-

Chest Style Ute Toolbox

>

-

1500 x 500 x 450mm Aluminium Checker Top Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

1500 x 500 x 450mm Aluminium Checker Top Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:... -

1200 x 600 x 500mm Aluminium Top Chest Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & Canopy(Chest Style)Thickness:...

1200 x 600 x 500mm Aluminium Top Chest Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & Canopy(Chest Style)Thickness:... -

1400 x 600 x 500mm Aluminium Top Chest Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

1400 x 600 x 500mm Aluminium Top Chest Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

-

- Tub Liner Ute Toolbox >

- Job Site Toolbox >

-

Camper Ute Toolbox

>

-

1500 x 400 x 400mm Aluminium Checker 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:...

1500 x 400 x 400mm Aluminium Checker 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:... -

1500 x 500 x 500mm Raw Flat Aluminium 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:...

1500 x 500 x 500mm Raw Flat Aluminium 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:... -

2000 x 500 x 500mm Aluminium 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:...

2000 x 500 x 500mm Aluminium 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:... -

610 x 330 x 540mm Aluminium Checker Ute Toolbox Trailer Camper Caravan Generator Tool Box for Honda 2kvaThickness:...

610 x 330 x 540mm Aluminium Checker Ute Toolbox Trailer Camper Caravan Generator Tool Box for Honda 2kvaThickness:... -

700 x 450 x 650mm Aluminium Checker Ute Toolbox Trailer Camper Caravan Generator Tool BoxThickness:...

700 x 450 x 650mm Aluminium Checker Ute Toolbox Trailer Camper Caravan Generator Tool BoxThickness:... -

760 x 500 x 560mm Aluminium Checker Ute Toolbox Trailer Camper Caravan Generator Tool BoxThickness:...

760 x 500 x 560mm Aluminium Checker Ute Toolbox Trailer Camper Caravan Generator Tool BoxThickness:... -

1700 x 550 x 610mm Black Aluminium Checker Ute Truck Tool Box Fridge Slide & Webber BBQ Slide Camper ToolboxThickness:...

1700 x 550 x 610mm Black Aluminium Checker Ute Truck Tool Box Fridge Slide & Webber BBQ Slide Camper ToolboxThickness:... -

2200 x 550 x 550mm Aluminium 3 Lid Slides BBQ Generator Camper ToolboxThickness:...

2200 x 550 x 550mm Aluminium 3 Lid Slides BBQ Generator Camper ToolboxThickness:... -

1400 x 550 x 800mm Black Aluminium Checker Ute Toolbox Webber BBQ & Fridge Slide Camper Caravan Canopy Tool BoxThickness:...

1400 x 550 x 800mm Black Aluminium Checker Ute Toolbox Webber BBQ & Fridge Slide Camper Caravan Canopy Tool BoxThickness:... -

1700 x 550 x 800mm Black Aluminium Checker Ute Toolbox Webber BBQ & Fridge Slide Camper Caravan Canopy Tool BoxThickness:...

1700 x 550 x 800mm Black Aluminium Checker Ute Toolbox Webber BBQ & Fridge Slide Camper Caravan Canopy Tool BoxThickness:... -

2000 x 550 x 800mm Black Aluminium Checker Ute Toolbox Webber BBQ & Fridge Slide Camper Caravan Canopy Tool BoxThickness:...

2000 x 550 x 800mm Black Aluminium Checker Ute Toolbox Webber BBQ & Fridge Slide Camper Caravan Canopy Tool BoxThickness:...

-

-

Cross Deck Gullwing

>

-

1500 x 500 x 500mm Raw Flat Aluminium 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:...

1500 x 500 x 500mm Raw Flat Aluminium 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:... -

2000 x 500 x 500mm Aluminium 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:...

2000 x 500 x 500mm Aluminium 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:... -

1770 x 600 x 500mm Aluminium Checker Sloped Top Gullwing Cross Deck Dual 2 Lid Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

1770 x 600 x 500mm Aluminium Checker Sloped Top Gullwing Cross Deck Dual 2 Lid Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:... -

1770 x 600 x 500mm Aluminium Checker Flat Top Gullwing Cross Deck Dual 2 Lid Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

1770 x 600 x 500mm Aluminium Checker Flat Top Gullwing Cross Deck Dual 2 Lid Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

-

-

Rectangle Ute Toolbox

>

-

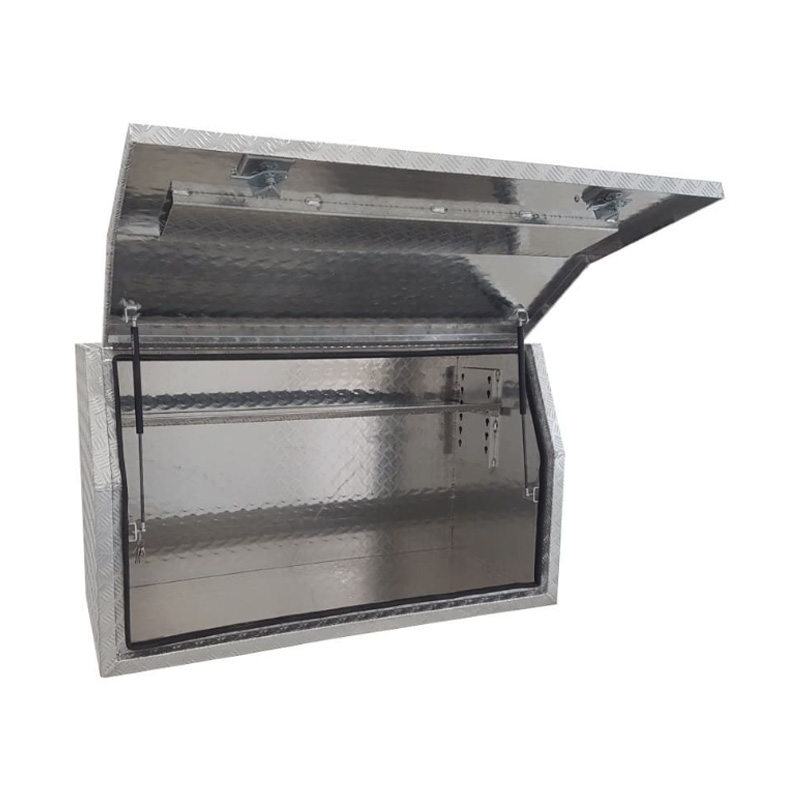

Side Opening Toolboxes

>

-

Half Lid Opening Ute Toolbox

>

-

1200 x 600 x 700mm Aluminium Checker Tool Box Ute Truck Fridge Trailer 3/4 Angle Storage ToolboxThickness:...

1200 x 600 x 700mm Aluminium Checker Tool Box Ute Truck Fridge Trailer 3/4 Angle Storage ToolboxThickness:... -

1400 x 600 x 700mm Aluminium Checker Tool Box Ute Truck Fridge Trailer 3/4 Angle Storage ToolboxThickness:...

1400 x 600 x 700mm Aluminium Checker Tool Box Ute Truck Fridge Trailer 3/4 Angle Storage ToolboxThickness:... -

1400 x 500 x 700mm Aluminium Checker 3/4 Half Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingxThickness:...

1400 x 500 x 700mm Aluminium Checker 3/4 Half Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingxThickness:... -

1700 x 500 x 700mm Aluminium Checker 3/4 Half Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1700 x 500 x 700mm Aluminium Checker 3/4 Half Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1400 x 600 x 820mm Aluminium Checker Full or Half Side Multi Lid Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1400 x 600 x 820mm Aluminium Checker Full or Half Side Multi Lid Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1700 x 600 x 820mm Aluminium Full or Half Side Multi Lid Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1700 x 600 x 820mm Aluminium Full or Half Side Multi Lid Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

900 x 600 x 820mm Aluminium Checker 3/4 Half Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

900 x 600 x 820mm Aluminium Checker 3/4 Half Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1200 x 600 x 820mm Aluminium Checker 3/4 Half Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1200 x 600 x 820mm Aluminium Checker 3/4 Half Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1400 x 600 x 820mm Aluminium 3/4 Half Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1400 x 600 x 820mm Aluminium 3/4 Half Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1700 x 600 x 820mm Aluminium 3/4 Half Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1700 x 600 x 820mm Aluminium 3/4 Half Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

2100 x 600 x 820mm Aluminium 3/4 Half Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

2100 x 600 x 820mm Aluminium 3/4 Half Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

-

-

Half Lid Ute Toolbox With Drawers

>

-

1500 x 600 x 820mm Aluminium Checker 3/4 Half Side Opening 2 Drawer Slide Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1500 x 600 x 820mm Aluminium Checker 3/4 Half Side Opening 2 Drawer Slide Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1400 x 600 x 820mm Aluminium 3/4 Half Side Opening 2 Drawer Slide Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1400 x 600 x 820mm Aluminium 3/4 Half Side Opening 2 Drawer Slide Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1700 x 600 x 820mm Aluminium 3/4 Half Side Opening 3 Drawer Slide Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1700 x 600 x 820mm Aluminium 3/4 Half Side Opening 3 Drawer Slide Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

2100 x 600 x 820mm Aluminium 3/4 Half Side Opening 3 Drawer Slide Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

2100 x 600 x 820mm Aluminium 3/4 Half Side Opening 3 Drawer Slide Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

-

-

Full Lid Opening Ute Toolbox

>

-

1400 x 500 x 700mm Aluminium Checker Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1400 x 500 x 700mm Aluminium Checker Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1700 x 500 x 700mm Aluminium Checker Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1700 x 500 x 700mm Aluminium Checker Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1400 x 600 x 820mm Aluminium Checker Full or Half Side Multi Lid Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1400 x 600 x 820mm Aluminium Checker Full or Half Side Multi Lid Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1400 x 600 x 820mm Aluminium Checker Full Side Opening Square Edge Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1400 x 600 x 820mm Aluminium Checker Full Side Opening Square Edge Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1700 x 600 x 820mm Aluminium Full or Half Side Multi Lid Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1700 x 600 x 820mm Aluminium Full or Half Side Multi Lid Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1700 x 600 x 820mm Aluminium Checker Full Side Opening Square Edge Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1700 x 600 x 820mm Aluminium Checker Full Side Opening Square Edge Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

900 x 600 x 820mm Aluminium Checker Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

900 x 600 x 820mm Aluminium Checker Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1000 x 530 x 820mm Aluminium Checker Side Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

1000 x 530 x 820mm Aluminium Checker Side Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:... -

1200 x 600 x 820mm Aluminium Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1200 x 600 x 820mm Aluminium Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1400 x 530 x 820mm Aluminium Checker Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1400 x 530 x 820mm Aluminium Checker Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1400 x 600 x 820mm Aluminium Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1400 x 600 x 820mm Aluminium Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1500 x 530 x 820mm Aluminium Checker Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1500 x 530 x 820mm Aluminium Checker Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1600 x 530 x 820mm Aluminium Checker Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1600 x 530 x 820mm Aluminium Checker Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1600 x 600 x 820mm Aluminium Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1600 x 600 x 820mm Aluminium Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1700 x 530 x 820mm Aluminium Checker Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1700 x 530 x 820mm Aluminium Checker Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1700 x 600 x 820mm Aluminium Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1700 x 600 x 820mm Aluminium Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1800 x 530 x 820mm Aluminium Checker Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1800 x 530 x 820mm Aluminium Checker Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1900 x 530 x 820mm Aluminium Checker Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1900 x 530 x 820mm Aluminium Checker Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

2100 x 600 x 820mm Aluminium Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

2100 x 600 x 820mm Aluminium Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1900 x 600 x 820mm Aluminium Full Side Opening Truck Tool Box HIGH Side Trailer Toolbox ShelvingThickness:...

1900 x 600 x 820mm Aluminium Full Side Opening Truck Tool Box HIGH Side Trailer Toolbox ShelvingThickness:...

-

-

Full Lid Ute Toolbox With Drawers

>

-

1400 x 600 x 820mm Aluminium Full Side Opening 2 Drawer Slide Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1400 x 600 x 820mm Aluminium Full Side Opening 2 Drawer Slide Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1400 x 600 x 820mm Aluminium Full Side Opening 4 Drawer Slide Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1400 x 600 x 820mm Aluminium Full Side Opening 4 Drawer Slide Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1700 x 600 x 820mm Aluminium Full Side Opening 2 Drawer Slide Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1700 x 600 x 820mm Aluminium Full Side Opening 2 Drawer Slide Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1700 x 600 x 820mm Aluminium Full Side Opening 4 Drawer Slide Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1700 x 600 x 820mm Aluminium Full Side Opening 4 Drawer Slide Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

-

-

Multi-Lid Ute Toolbox

>

-

1770 x 600 x 500mm Aluminium Checker Sloped Top Gullwing Cross Deck Dual 2 Lid Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

1770 x 600 x 500mm Aluminium Checker Sloped Top Gullwing Cross Deck Dual 2 Lid Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:... -

1770 x 600 x 500mm Aluminium Checker Flat Top Gullwing Cross Deck Dual 2 Lid Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

1770 x 600 x 500mm Aluminium Checker Flat Top Gullwing Cross Deck Dual 2 Lid Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:... -

1400 x 600 x 820mm Aluminium Checker Full or Half Side Multi Lid Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1400 x 600 x 820mm Aluminium Checker Full or Half Side Multi Lid Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1700 x 600 x 820mm Aluminium Full or Half Side Multi Lid Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1700 x 600 x 820mm Aluminium Full or Half Side Multi Lid Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1400 x 600 x 820mm Aluminium Checker Full or Half Side Multi Lid Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1400 x 600 x 820mm Aluminium Checker Full or Half Side Multi Lid Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1700 x 600 x 820mm Aluminium Full or Half Side Multi Lid Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1700 x 600 x 820mm Aluminium Full or Half Side Multi Lid Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

-

-

Half Lid Opening Ute Toolbox

>

-

Truck Toolboxes

>

-

Under Truck Tool Boxes

>

-

600 x 450 x 450mm Aluminium Checker Under Tray Body Tool box Truck Storage ToolboxThickness:...

600 x 450 x 450mm Aluminium Checker Under Tray Body Tool box Truck Storage ToolboxThickness:... -

600 x 450 x 450mm Flat Aluminium Under Tray Body Tool box Truck Storage ToolboxThickness:...

600 x 450 x 450mm Flat Aluminium Under Tray Body Tool box Truck Storage ToolboxThickness:... -

900 x 450 x 450mm Flat Aluminium Under Tray Body Tool box Truck Storage ToolboxThickness:...

900 x 450 x 450mm Flat Aluminium Under Tray Body Tool box Truck Storage ToolboxThickness:... -

1000 x 450 x 450mm Flat Aluminium Under Tray Body Tool box Truck Storage ToolboxThickness:...

1000 x 450 x 450mm Flat Aluminium Under Tray Body Tool box Truck Storage ToolboxThickness:... -

1200 x 450 x 450mm Flat Aluminium Under Tray Body Tool box Truck Storage ToolboxThickness:...

1200 x 450 x 450mm Flat Aluminium Under Tray Body Tool box Truck Storage ToolboxThickness:... -

600 x 500 x 500mm Black Aluminium Under Tray Slide Drawer Body Tool box Truck Storage ToolboxThickness:...

600 x 500 x 500mm Black Aluminium Under Tray Slide Drawer Body Tool box Truck Storage ToolboxThickness:... -

900 x 500 x 500mm Raw Flat Aluminium Under Tray Slide Drawer Body Tool box Truck Storage ToolboxThickness:...

900 x 500 x 500mm Raw Flat Aluminium Under Tray Slide Drawer Body Tool box Truck Storage ToolboxThickness:...

-

- Half Lid Truck Toolbox With Drawers >

-

Full Lid Opening Truck Toolbox

>

-

1400 x 600 x 1200mm Aluminium Full Side Opening Truck Tool Box HIGH Side Trailer Toolbox ShelvingThickness:...

1400 x 600 x 1200mm Aluminium Full Side Opening Truck Tool Box HIGH Side Trailer Toolbox ShelvingThickness:... -

1900 x 600 x 820mm Aluminium Full Side Opening Truck Tool Box HIGH Side Trailer Toolbox Shelving 1968SFD-CPThickness:...

1900 x 600 x 820mm Aluminium Full Side Opening Truck Tool Box HIGH Side Trailer Toolbox Shelving 1968SFD-CPThickness:... -

1900 x 600 x 1200mm Aluminium Checker Full Side Opening Truck Tool Box HIGH Side Trailer Toolbox ShelvingThickness:...

1900 x 600 x 1200mm Aluminium Checker Full Side Opening Truck Tool Box HIGH Side Trailer Toolbox ShelvingThickness:... -

1900 x 600 x 1200mm Checker PRO Full Side Truck Tool Box HIGH Side Toolbox Shelving ReinforcedThickness:...

1900 x 600 x 1200mm Checker PRO Full Side Truck Tool Box HIGH Side Toolbox Shelving ReinforcedThickness:... -

1900 x 600 x 1200mm Aluminium Flat PRO Full Side Truck Tool Box HIGH Side Toolbox Shelving ReinforcedThickness:...

1900 x 600 x 1200mm Aluminium Flat PRO Full Side Truck Tool Box HIGH Side Toolbox Shelving ReinforcedThickness:... -

1900 x 600 x 1200mm Aluminium 4 Drawer Full Side Truck Tool Box HIGH Side Trailer Toolbox ShelvingThickness:...

1900 x 600 x 1200mm Aluminium 4 Drawer Full Side Truck Tool Box HIGH Side Trailer Toolbox ShelvingThickness:... -

1400 x 600 x 820mm Aluminium Checker Full Side Opening Square Edge Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1400 x 600 x 820mm Aluminium Checker Full Side Opening Square Edge Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1700 x 600 x 820mm Aluminium Checker Full Side Opening Square Edge Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1700 x 600 x 820mm Aluminium Checker Full Side Opening Square Edge Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

-

- Full Lid Truck Toolbox With Drawers >

-

Under Truck Tool Boxes

>

- Dog Boxes >

-

Toolbox Canopies

>

-

1770 x 600 x 500mm Aluminium Checker Sloped Top Gullwing Cross Deck Dual 2 Lid Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

1770 x 600 x 500mm Aluminium Checker Sloped Top Gullwing Cross Deck Dual 2 Lid Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:... -

1770 x 600 x 500mm Aluminium Checker Flat Top Gullwing Cross Deck Dual 2 Lid Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

1770 x 600 x 500mm Aluminium Checker Flat Top Gullwing Cross Deck Dual 2 Lid Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:... -

1600 x 700 x 820mm Aluminium Ute Truck Trailer Toolbox Canopy Gullwing 1678-CP-SLDThickness:...

1600 x 700 x 820mm Aluminium Ute Truck Trailer Toolbox Canopy Gullwing 1678-CP-SLDThickness:... -

1770 x 700 x 820mm Aluminium Ute Tool Box Truck Trailer Full Lid Part Canopy ToolboxThickness:...

1770 x 700 x 820mm Aluminium Ute Tool Box Truck Trailer Full Lid Part Canopy ToolboxThickness:... -

1770 x 800 x 820mm Flat Aluminium Ute Tool Box Truck Trailer Full Lid Part Canopy ToolboxThickness:...

1770 x 800 x 820mm Flat Aluminium Ute Tool Box Truck Trailer Full Lid Part Canopy ToolboxThickness:... -

1770 x 1200 x 820mm Aluminium Checker Full Side Part Canopy Tool Box Ute Truck Trailer Toolbox Storage Gullwing ShelvingThickness:...

1770 x 1200 x 820mm Aluminium Checker Full Side Part Canopy Tool Box Ute Truck Trailer Toolbox Storage Gullwing ShelvingThickness:...

-

-

Camper & Trailer Boxes

>

-

Trailer Boxes/Draw bar Boxes

>

-

900 x 400 x 400mm Aluminium Checker Top Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

900 x 400 x 400mm Aluminium Checker Top Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:... -

1220 x 400 x 350mm Aluminium Top Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

1220 x 400 x 350mm Aluminium Top Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:... -

1220 x 500 x 500mm Aluminium Top Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & Canopy 1255Thickness:...

1220 x 500 x 500mm Aluminium Top Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & Canopy 1255Thickness:... -

1500 x 500 x 450mm Aluminium Checker Top Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

1500 x 500 x 450mm Aluminium Checker Top Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:... -

1200 x 600 x 700mm Aluminium Checker Tool Box Ute Truck Fridge Trailer 3/4 Angle Storage ToolboxThickness:...

1200 x 600 x 700mm Aluminium Checker Tool Box Ute Truck Fridge Trailer 3/4 Angle Storage ToolboxThickness:... -

1400 x 600 x 700mm Aluminium Checker Tool Box Ute Truck Fridge Trailer 3/4 Angle Storage ToolboxThickness:...

1400 x 600 x 700mm Aluminium Checker Tool Box Ute Truck Fridge Trailer 3/4 Angle Storage ToolboxThickness:... -

1500 x 400 x 400mm Aluminium Checker 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:...

1500 x 400 x 400mm Aluminium Checker 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:... -

1500 x 500 x 500mm Raw Flat Aluminium 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:...

1500 x 500 x 500mm Raw Flat Aluminium 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:... -

2000 x 500 x 500mm Aluminium 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:...

2000 x 500 x 500mm Aluminium 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:... -

1700 x 550 x 610mm Black Aluminium Checker Ute Truck Tool Box Fridge Slide & Webber BBQ Slide Camper ToolboxThickness:...

1700 x 550 x 610mm Black Aluminium Checker Ute Truck Tool Box Fridge Slide & Webber BBQ Slide Camper ToolboxThickness:... -

2200 x 550 x 550mm Aluminium 3 Lid Slides BBQ Generator Camper ToolboxThickness:...

2200 x 550 x 550mm Aluminium 3 Lid Slides BBQ Generator Camper ToolboxThickness:... -

1400 x 550 x 800mm Black Aluminium Checker Ute Toolbox Webber BBQ & Fridge Slide Camper Caravan Canopy Tool BoxThickness:...

1400 x 550 x 800mm Black Aluminium Checker Ute Toolbox Webber BBQ & Fridge Slide Camper Caravan Canopy Tool BoxThickness:... -

1700 x 550 x 800mm Black Aluminium Checker Ute Toolbox Webber BBQ & Fridge Slide Camper Caravan Canopy Tool BoxThickness:...

1700 x 550 x 800mm Black Aluminium Checker Ute Toolbox Webber BBQ & Fridge Slide Camper Caravan Canopy Tool BoxThickness:... -

2000 x 550 x 800mm Black Aluminium Checker Ute Toolbox Webber BBQ & Fridge Slide Camper Caravan Canopy Tool BoxThickness:...

2000 x 550 x 800mm Black Aluminium Checker Ute Toolbox Webber BBQ & Fridge Slide Camper Caravan Canopy Tool BoxThickness:... -

1770 x 600 x 500mm Aluminium Checker Sloped Top Gullwing Cross Deck Dual 2 Lid Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

1770 x 600 x 500mm Aluminium Checker Sloped Top Gullwing Cross Deck Dual 2 Lid Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:... -

1770 x 600 x 500mm Aluminium Checker Flat Top Gullwing Cross Deck Dual 2 Lid Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

1770 x 600 x 500mm Aluminium Checker Flat Top Gullwing Cross Deck Dual 2 Lid Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:... -

860 x 460 x 460mm Aluminium Checker Toolbox Trailer Draw Bar Storage DrawBar Tool BoxThickness:...

860 x 460 x 460mm Aluminium Checker Toolbox Trailer Draw Bar Storage DrawBar Tool BoxThickness:... -

1200 x 500 x 500mm Aluminium Toolbox Trailer Draw Bar Storage DrawBar Tool BoxThickness:...

1200 x 500 x 500mm Aluminium Toolbox Trailer Draw Bar Storage DrawBar Tool BoxThickness:... -

1400 x 580 x 820mm Aluminium Checker Full Side Center Box Caravan Ute Tool Box Truck Cab Trailer ToolboxThickness:...

1400 x 580 x 820mm Aluminium Checker Full Side Center Box Caravan Ute Tool Box Truck Cab Trailer ToolboxThickness:... -

1700 x 580 x 820mm Aluminium Checker Full Side Center Box Caravan Ute Tool Box Truck Cab Trailer ToolboxThickness:...

1700 x 580 x 820mm Aluminium Checker Full Side Center Box Caravan Ute Tool Box Truck Cab Trailer ToolboxThickness:...

-

-

Caravan Boxes

>

-

1500 x 400 x 400mm Aluminium Checker 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:...

1500 x 400 x 400mm Aluminium Checker 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:... -

1500 x 500 x 500mm Raw Flat Aluminium 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:...

1500 x 500 x 500mm Raw Flat Aluminium 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:... -

2000 x 500 x 500mm Aluminium 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:...

2000 x 500 x 500mm Aluminium 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:... -

1700 x 550 x 610mm Black Aluminium Checker Ute Truck Tool Box Fridge Slide & Webber BBQ Slide Camper ToolboxThickness:...

1700 x 550 x 610mm Black Aluminium Checker Ute Truck Tool Box Fridge Slide & Webber BBQ Slide Camper ToolboxThickness:... -

2200 x 550 x 550mm Aluminium 3 Lid Slides BBQ Generator Camper ToolboxThickness:...

2200 x 550 x 550mm Aluminium 3 Lid Slides BBQ Generator Camper ToolboxThickness:... -

1400 x 550 x 800mm Black Aluminium Checker Ute Toolbox Webber BBQ & Fridge Slide Camper Caravan Canopy Tool BoxThickness:...

1400 x 550 x 800mm Black Aluminium Checker Ute Toolbox Webber BBQ & Fridge Slide Camper Caravan Canopy Tool BoxThickness:... -

1700 x 550 x 800mm Black Aluminium Checker Ute Toolbox Webber BBQ & Fridge Slide Camper Caravan Canopy Tool BoxThickness:...

1700 x 550 x 800mm Black Aluminium Checker Ute Toolbox Webber BBQ & Fridge Slide Camper Caravan Canopy Tool BoxThickness:... -

2000 x 550 x 800mm Black Aluminium Checker Ute Toolbox Webber BBQ & Fridge Slide Camper Caravan Canopy Tool BoxThickness:...

2000 x 550 x 800mm Black Aluminium Checker Ute Toolbox Webber BBQ & Fridge Slide Camper Caravan Canopy Tool BoxThickness:... -

1600 x 700 x 820mm Aluminium Ute Truck Trailer Toolbox Canopy Gullwing 1678-CP-SLDThickness:...

1600 x 700 x 820mm Aluminium Ute Truck Trailer Toolbox Canopy Gullwing 1678-CP-SLDThickness:...

-

-

Generator Boxes

>

-

610 x 330 x 540mm Aluminium Checker Ute Toolbox Trailer Camper Caravan Generator Tool Box for Honda 2kvaThickness:...

610 x 330 x 540mm Aluminium Checker Ute Toolbox Trailer Camper Caravan Generator Tool Box for Honda 2kvaThickness:... -

700 x 450 x 650mm Aluminium Checker Ute Toolbox Trailer Camper Caravan Generator Tool BoxThickness:...

700 x 450 x 650mm Aluminium Checker Ute Toolbox Trailer Camper Caravan Generator Tool BoxThickness:... -

760 x 500 x 560mm Aluminium Checker Ute Toolbox Trailer Camper Caravan Generator Tool BoxThickness:...

760 x 500 x 560mm Aluminium Checker Ute Toolbox Trailer Camper Caravan Generator Tool BoxThickness:...

-

-

Trailer Boxes/Draw bar Boxes

>

-

Under Tray Toolboxes

>

- Accessories

-

Trailers Accessories

>

- Trailer Jockey Wheel >

-

Trailer Coupler

>

-

AU 2/3 Hole Quick Release 50 mm Non Braked CouplerSuits 50mm...

AU 2/3 Hole Quick Release 50 mm Non Braked CouplerSuits 50mm... -

AU 50 mm Mechanical Brake CouplerSuits 50mm...

AU 50 mm Mechanical Brake CouplerSuits 50mm... -

AU Electric Coupling 50 mm Towball 3.5T RatedSuits 50mm...

AU Electric Coupling 50 mm Towball 3.5T RatedSuits 50mm... -

NZ 1-7/8 Non Braked CouplerSuits 45mm...

NZ 1-7/8 Non Braked CouplerSuits 45mm... -

NZ 1-7/8 Mechanical Brake CouplerSuits 45mm...

NZ 1-7/8 Mechanical Brake CouplerSuits 45mm... -

NZ Electric Coupling 50 mm Towball 3.5T RatedSuits 50mm...

NZ Electric Coupling 50 mm Towball 3.5T RatedSuits 50mm...

-

-

Trailer Spring

>

-

Slipper to Eye Spring, 6×45×5

Slipper to Eye Spring, 6×45×5 -

Slipper to Eye Spring, 6×45×6

Slipper to Eye Spring, 6×45×6 -

Slipper to Eye Spring, 6×45×7

Slipper to Eye Spring, 6×45×7 -

Eye to Eye Spring, 8×45×5

Eye to Eye Spring, 8×45×5 -

Eye to Eye Spring, 8×45×7

Eye to Eye Spring, 8×45×7 -

Eye to Eye Spring 6×45×5

Eye to Eye Spring 6×45×5 -

Leaf Rocker Roller Spring, 6×60×7

Leaf Rocker Roller Spring, 6×60×7 -

Leaf Rocker Roller Spring, 6×60×9

Leaf Rocker Roller Spring, 6×60×9 -

Boat trailer Slipper to Eye Spring 6×45×5

Boat trailer Slipper to Eye Spring 6×45×5 -

Boat trailer Slipper to Eye Spring 6×45×7

Boat trailer Slipper to Eye Spring 6×45×7

-

- Trailer Axle >

- Trailer Brake >

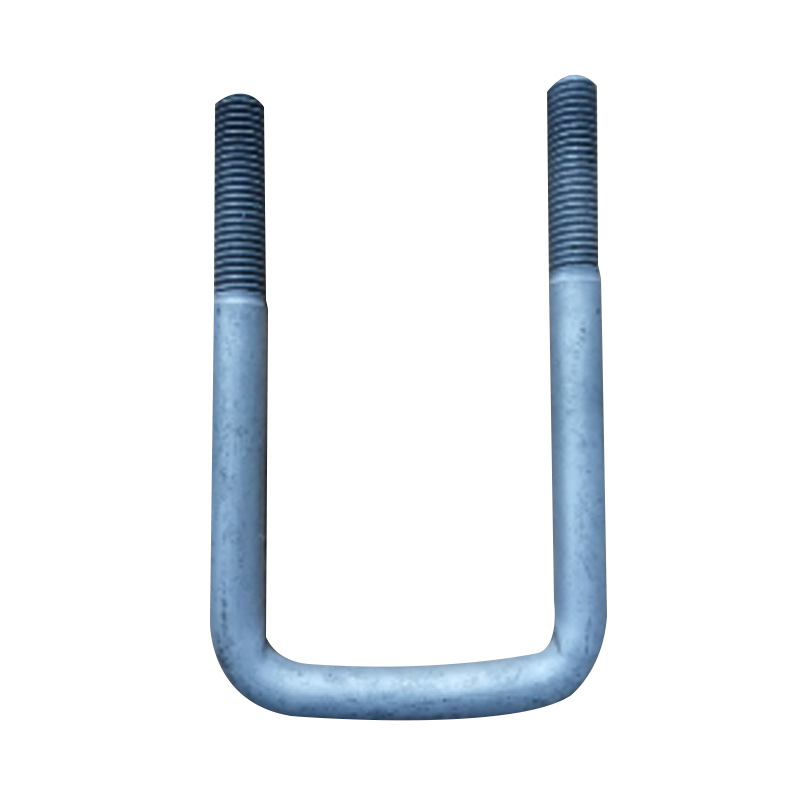

- Trailer U Bolt >

- Trailer Wheel >

-

Trailer Mudguard

>

-

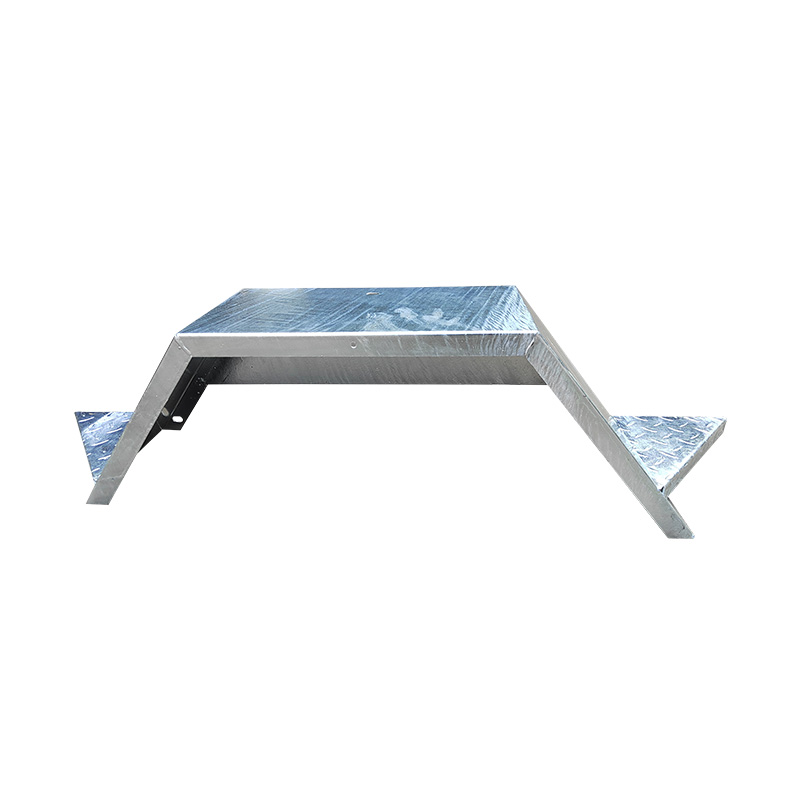

13" Single Axle Galvanized Trailer MudguardThis 13-in...

13" Single Axle Galvanized Trailer MudguardThis 13-in... -

14" Single Axle Galvanized Trailer MudguardBuilt for ...

14" Single Axle Galvanized Trailer MudguardBuilt for ... -

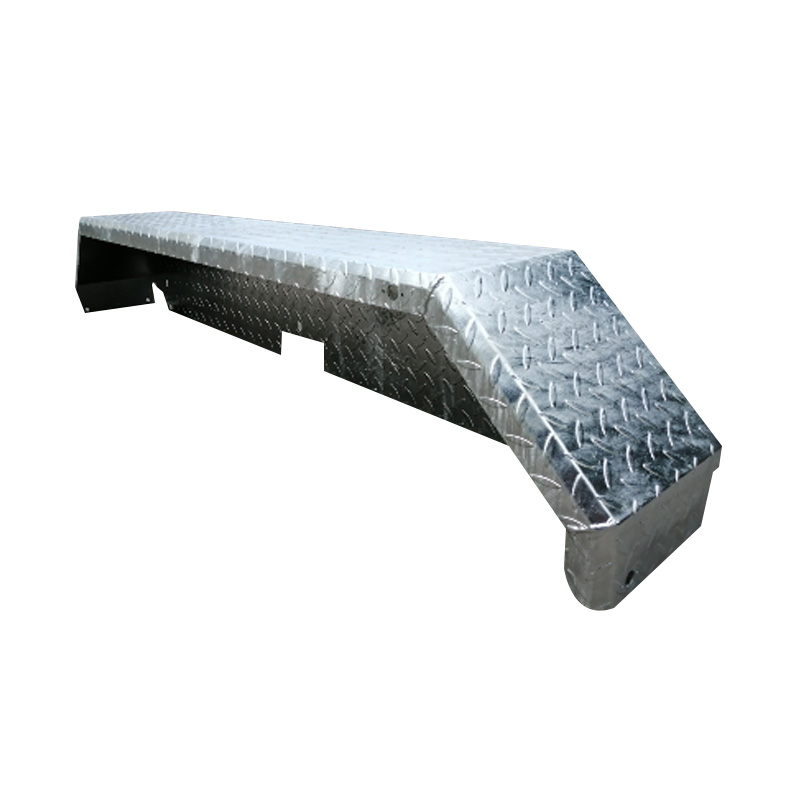

14" Single Axle Galvanized Trailer Mudguard with Side StepThis 14-in...

14" Single Axle Galvanized Trailer Mudguard with Side StepThis 14-in... -

14" Single Axle Round Galvanized Trailer MudguardCrafted wi...

14" Single Axle Round Galvanized Trailer MudguardCrafted wi... -

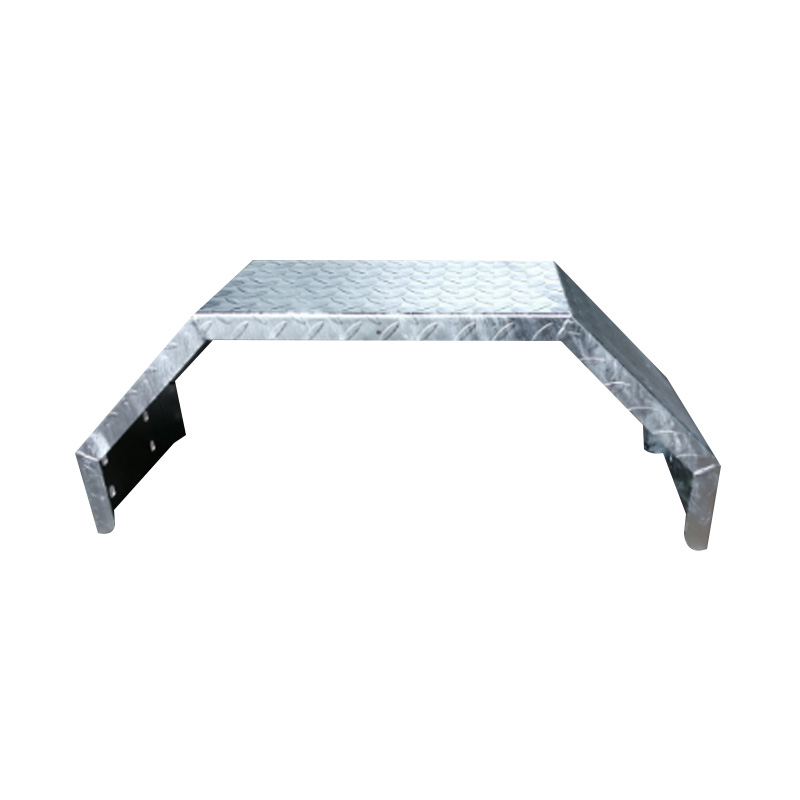

14" Tandem Galvanized Trailer MudguardEngineered...

14" Tandem Galvanized Trailer MudguardEngineered... -

14" Tandem Aluminum Trailer MudguardThis 14-in...

14" Tandem Aluminum Trailer MudguardThis 14-in...

-

-

Trailer Light

>

-

LED Tail light M/Volt 107 x 99 mm 12/24V without Number Plate LightTrailer li...

LED Tail light M/Volt 107 x 99 mm 12/24V without Number Plate LightTrailer li... -

LED Tail light M/Volt 107 x 99 mm 12/24V with Number Plate LightTrailer li...

LED Tail light M/Volt 107 x 99 mm 12/24V with Number Plate LightTrailer li... -

White- LED SIDE Marker 60×38 mm M/Volt ClearTrailer si...

White- LED SIDE Marker 60×38 mm M/Volt ClearTrailer si... -

Yellow-LED SIDE Marker 59×35 mm M/Volt ClearTrailer si...

Yellow-LED SIDE Marker 59×35 mm M/Volt ClearTrailer si... -

Yellow & Red-LED SIDE 59×35 mm Marker M/Volt ClearTrailer si...

Yellow & Red-LED SIDE 59×35 mm Marker M/Volt ClearTrailer si... -

80×35 mm LED Number Plate LightTrailer nu...

80×35 mm LED Number Plate LightTrailer nu... -

70×30 mm Reflector Stick On AmberReflectors...

70×30 mm Reflector Stick On AmberReflectors... -

70×30 mm Reflector Stick On RedReflectors...

70×30 mm Reflector Stick On RedReflectors... -

70×30 mm Reflector Stick On ClearReflectors...

70×30 mm Reflector Stick On ClearReflectors...

-

- Trailer Cage >

- Trailer Canvas Cover >

-

Trailer Drawbar Toolbox

>

-

Side Open Trailer Drawbar Aluminum Toolbox with Fridge Slideavaiable f...

Side Open Trailer Drawbar Aluminum Toolbox with Fridge Slideavaiable f... -

Top Opening Trailer Drawbar Aluminum Toolboxavaiable f...

Top Opening Trailer Drawbar Aluminum Toolboxavaiable f... -

Checker Top Opening Trailer Drawbar Aluminum Toolboxavaiable f...

Checker Top Opening Trailer Drawbar Aluminum Toolboxavaiable f... -

3/4 Angle Toolbox Trailer Drawbar Aluminum Toolboxavaiable f...

3/4 Angle Toolbox Trailer Drawbar Aluminum Toolboxavaiable f... -

Aluminum Trailer Tongue Storage Toolbox with Lockavaiable f...

Aluminum Trailer Tongue Storage Toolbox with Lockavaiable f... -

Checker 3 Lid Ute Toolbox Trailer Drawbar Aluminum Toolboxavaiable f...

Checker 3 Lid Ute Toolbox Trailer Drawbar Aluminum Toolboxavaiable f... -

Aluminium 3 Lid Slides Trailer Drawbar Toolbox with Fridge Slideavaiable f...

Aluminium 3 Lid Slides Trailer Drawbar Toolbox with Fridge Slideavaiable f... -

Black Aluminium Ute Toolbox Fridge Slide Trailer Drawbar Toolboxavaiable f...

Black Aluminium Ute Toolbox Fridge Slide Trailer Drawbar Toolboxavaiable f... -

Black Trailer Drawbar Aluminum Toolbox with Fridge Slideavaiable f...

Black Trailer Drawbar Aluminum Toolbox with Fridge Slideavaiable f... -

Gullwing 2 Lid Trailer Drawbar Aluminum Toolboxavaiable f...

Gullwing 2 Lid Trailer Drawbar Aluminum Toolboxavaiable f... -

Checker Flat Top Dual 2 Lid Trailer Drawbar Aluminum Toolboxavaiable f...

Checker Flat Top Dual 2 Lid Trailer Drawbar Aluminum Toolboxavaiable f... -

Full Side Opening Door Trailer Drawbar Aluminum Toolboxavaiable f...

Full Side Opening Door Trailer Drawbar Aluminum Toolboxavaiable f...

-

- Trailer Mower Box >

- Trailer H Bar >

- Trailer Spare Wheel Holder >

-

Toolbox Accessories

>

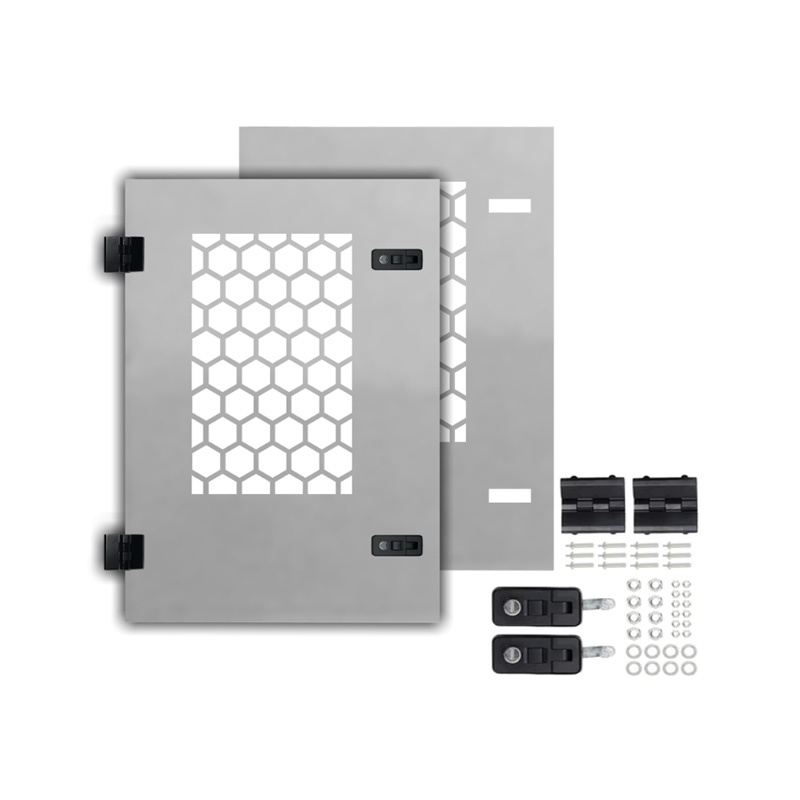

- Toolbox Mounting Kit >

-

Toolbox Locks

>

-

Stainless Steel T-Lock STUD MountMaterial: ...

Stainless Steel T-Lock STUD MountMaterial: ... -

12V Recessed Folding Padlock Friendly Whale Tail Handle ACT-WTLOCKKey lockin...

12V Recessed Folding Padlock Friendly Whale Tail Handle ACT-WTLOCKKey lockin... -

Whale Tail T-Lock Padlockable Whale Tail HandleKey lockin...

Whale Tail T-Lock Padlockable Whale Tail HandleKey lockin... -

Black Whale Tail T-Lock Padlockable Whale Tail HandleKey lockin...

Black Whale Tail T-Lock Padlockable Whale Tail HandleKey lockin... -

Chome & Black Whale Tail T-Lock Padlockable Whale Tail HandleKey lockin...

Chome & Black Whale Tail T-Lock Padlockable Whale Tail HandleKey lockin... -

White Whale Tail T-Lock Padlockable Whale Tail HandleKey lockin...

White Whale Tail T-Lock Padlockable Whale Tail HandleKey lockin...

-

-

Toolbox Drawer Unites

>

-

600 x 430 x 450mm Black Aluminium 3 Drawer Unit for Ute Truck Tool box Canopy Caravan Tool BoxThickness:...

600 x 430 x 450mm Black Aluminium 3 Drawer Unit for Ute Truck Tool box Canopy Caravan Tool BoxThickness:... -

600 x 430 x 620mm Black Aluminium 4 Drawer Unit for Ute Truck Tool box Canopy Caravan Tool BoxThickness:...

600 x 430 x 620mm Black Aluminium 4 Drawer Unit for Ute Truck Tool box Canopy Caravan Tool BoxThickness:... -

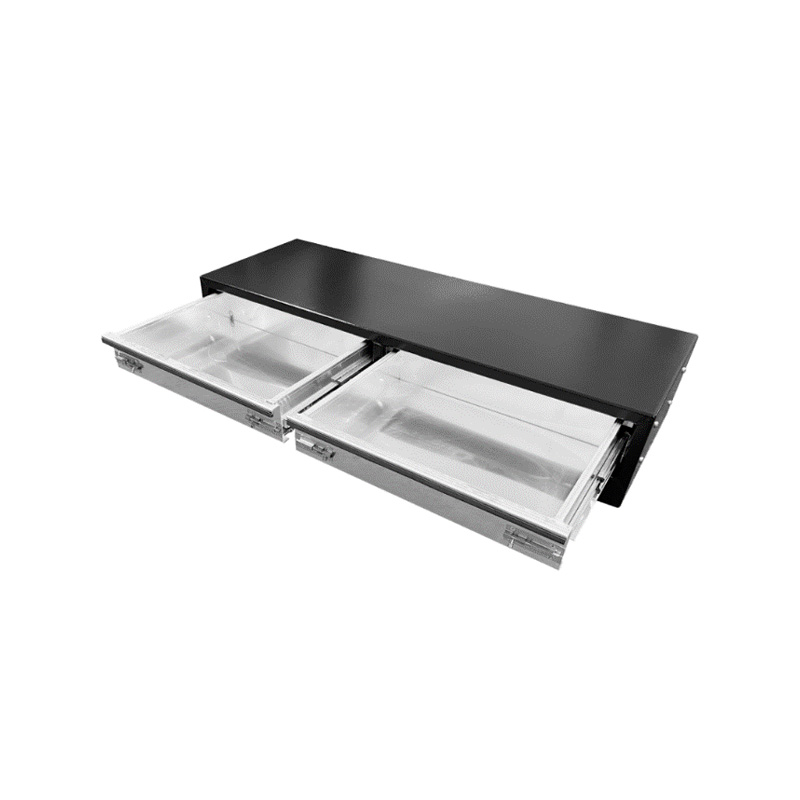

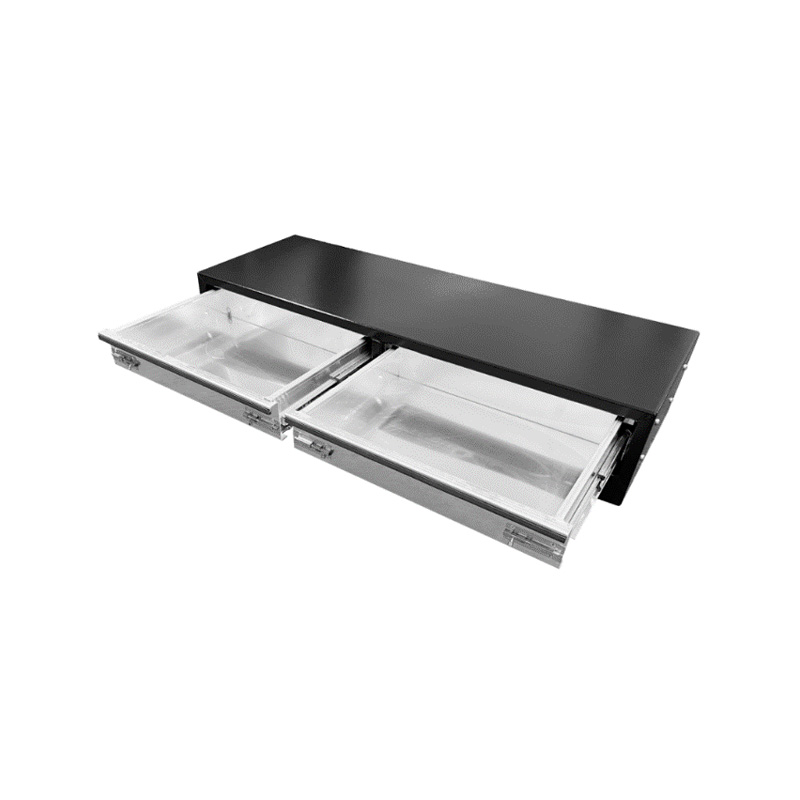

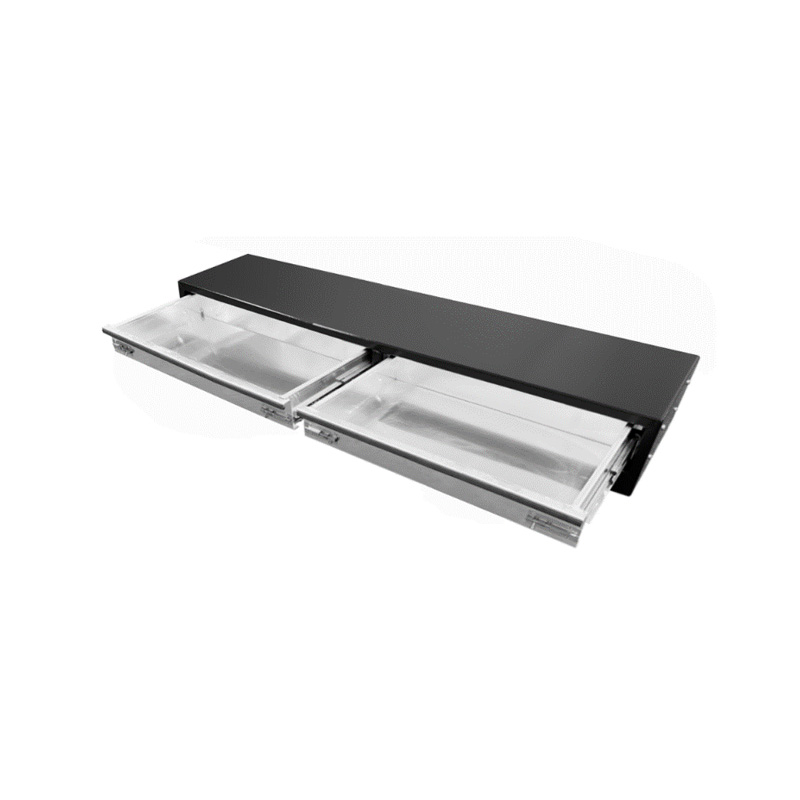

1020 x 440 x 230mm Black Aluminium 2 Drawer Unit for Ute Truck Tool box Canopy Caravan ToolboxThickness:...

1020 x 440 x 230mm Black Aluminium 2 Drawer Unit for Ute Truck Tool box Canopy Caravan ToolboxThickness:... -

1220 x 440 x 230mm Black Aluminium 2 Drawer Unit for Ute Truck Tool box Canopy Caravan ToolboxThickness:...

1220 x 440 x 230mm Black Aluminium 2 Drawer Unit for Ute Truck Tool box Canopy Caravan ToolboxThickness:... -

520 x 440 x 230mm Black Aluminium 2 Drawer Unit for Ute Truck Tool box Canopy Caravan ToolboxThickness:...

520 x 440 x 230mm Black Aluminium 2 Drawer Unit for Ute Truck Tool box Canopy Caravan ToolboxThickness:... -

1920 x 440 x 230mm Black Aluminium 2 Drawer Unit for Ute Truck Tool box Canopy Caravan Tool BoxThickness:...

1920 x 440 x 230mm Black Aluminium 2 Drawer Unit for Ute Truck Tool box Canopy Caravan Tool BoxThickness:... -

1400 x 600 x 380mm 1 Drawer Unit for Ute Truck Tool box Canopy Caravan ToolboxThickness:...

1400 x 600 x 380mm 1 Drawer Unit for Ute Truck Tool box Canopy Caravan ToolboxThickness:... -

1400 x 600 x 380mm 2 Drawer Unit for Ute Truck Tool box Canopy Caravan ToolboxThickness:...

1400 x 600 x 380mm 2 Drawer Unit for Ute Truck Tool box Canopy Caravan ToolboxThickness:... -

1700 x 600 x 380mm 3 Drawer Unit for Ute Truck Tool box Canopy Caravan ToolboxThickness:...

1700 x 600 x 380mm 3 Drawer Unit for Ute Truck Tool box Canopy Caravan ToolboxThickness:... -

1900 x 600 x 380mm 3 Drawer Unit for Ute Truck Tool box Canopy Caravan ToolboxThickness:...

1900 x 600 x 380mm 3 Drawer Unit for Ute Truck Tool box Canopy Caravan ToolboxThickness:... -

1.4m Aluminium Ute Tool box Under Tray Toolbox Trundle Roller Tray Slide Out Drawer Toolbox Benchtop LidThickness:...

1.4m Aluminium Ute Tool box Under Tray Toolbox Trundle Roller Tray Slide Out Drawer Toolbox Benchtop LidThickness:... -

1.6m Aluminium Ute Tool box Under Tray Toolbox Trundle Roller Tray Slide Out Drawer Toolbox Benchtop LidThickness:...

1.6m Aluminium Ute Tool box Under Tray Toolbox Trundle Roller Tray Slide Out Drawer Toolbox Benchtop LidThickness:... -

1.7m Aluminium Ute Tool box Under Tray Toolbox Trundle Roller Tray Slide Out Drawer Toolbox Benchtop LidThickness:...

1.7m Aluminium Ute Tool box Under Tray Toolbox Trundle Roller Tray Slide Out Drawer Toolbox Benchtop LidThickness:...

-

-

Toolbox Shelves

>

-

0.9m Shelf - For Aluminium Storage Toolbox Tool BoxThickness:...

0.9m Shelf - For Aluminium Storage Toolbox Tool BoxThickness:... -

1.2m Shelf - For Aluminium Storage Toolbox Tool BoxThickness:...

1.2m Shelf - For Aluminium Storage Toolbox Tool BoxThickness:... -

1.4m Shelf - For Aluminium Storage Toolbox Tool BoxThickness:...

1.4m Shelf - For Aluminium Storage Toolbox Tool BoxThickness:... -

1.5m Shelf - For Aluminium Storage Toolbox Tool BoxThickness:...

1.5m Shelf - For Aluminium Storage Toolbox Tool BoxThickness:... -

1.6m Shelf - For Aluminium Storage Toolbox Tool BoxThickness:...

1.6m Shelf - For Aluminium Storage Toolbox Tool BoxThickness:... -

1.7m Shelf - For Aluminium Storage Toolbox Tool BoxThickness:...

1.7m Shelf - For Aluminium Storage Toolbox Tool BoxThickness:... -

1.8m Shelf - For Aluminium Storage Toolbox Tool BoxThickness:...

1.8m Shelf - For Aluminium Storage Toolbox Tool BoxThickness:... -

1.9m Shelf - For Aluminium Storage Toolbox Tool BoxThickness:...

1.9m Shelf - For Aluminium Storage Toolbox Tool BoxThickness:... -

1.94m Shelf - For Aluminium Storage Toolbox Tool BoxThickness:...

1.94m Shelf - For Aluminium Storage Toolbox Tool BoxThickness:... -

2.1m Shelf - For Aluminium Storage Toolbox Tool BoxThickness:...

2.1m Shelf - For Aluminium Storage Toolbox Tool BoxThickness:...

-

-

Gas Strut

>

-

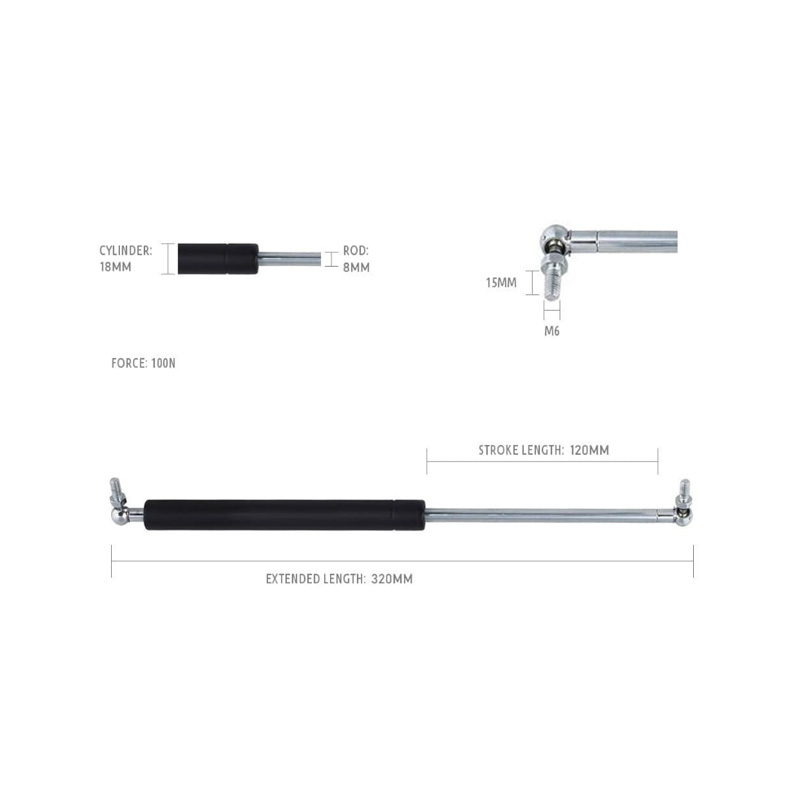

Gas Strut 120-320/100N GS120-320-100NExtended L...

Gas Strut 120-320/100N GS120-320-100NExtended L... -

Gas Strut 120-320/180N GS120-320-180NExtended L...

Gas Strut 120-320/180N GS120-320-180NExtended L... -

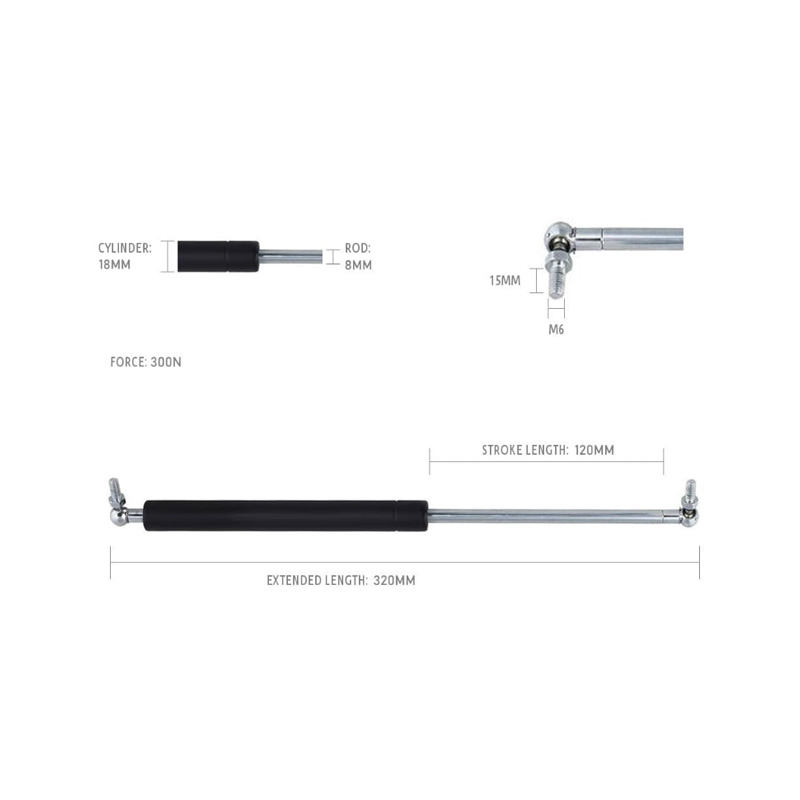

Gas Strut 120-320/300N GS120-320-300NExtended L...

Gas Strut 120-320/300N GS120-320-300NExtended L... -

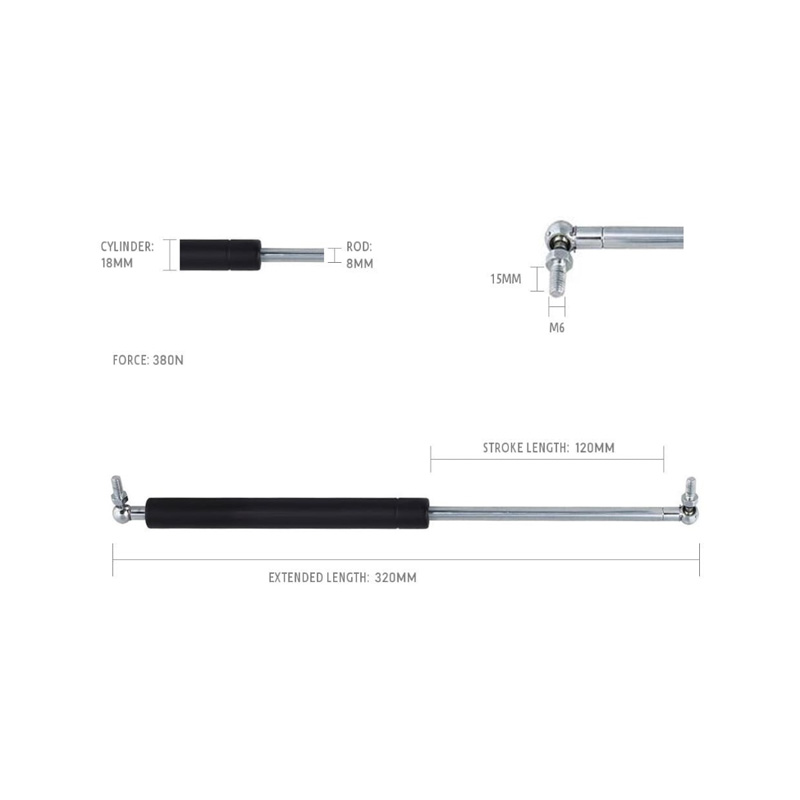

Gas Strut 120-320/380N GS120-320-380NExtended L...

Gas Strut 120-320/380N GS120-320-380NExtended L... -

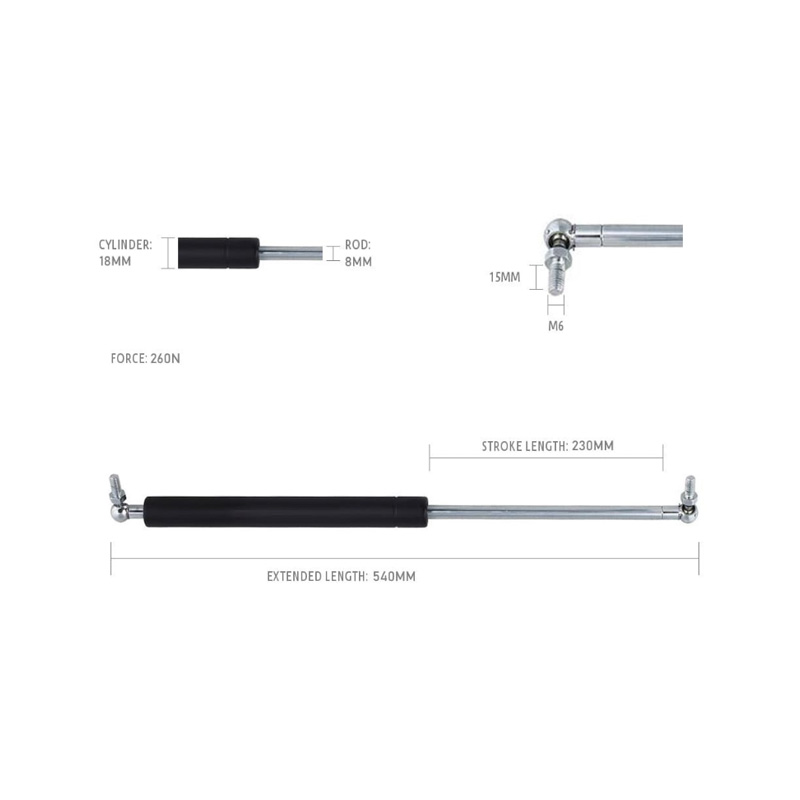

Gas Strut 230-540/260N GS230-540-260NExtended L...

Gas Strut 230-540/260N GS230-540-260NExtended L... -

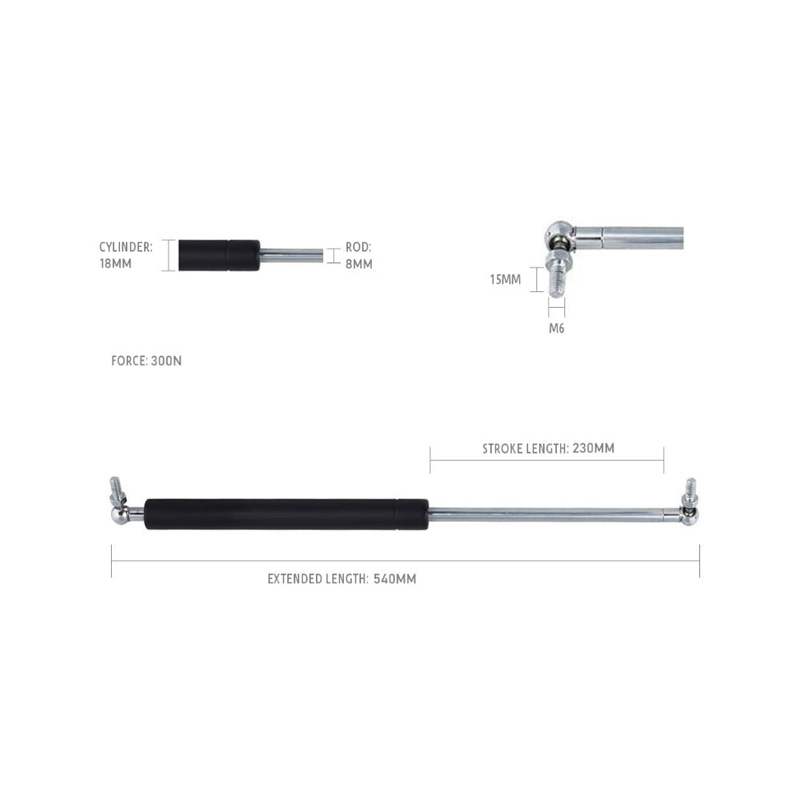

Gas Strut 230-540/300N GS230-540-300NExtended L...

Gas Strut 230-540/300N GS230-540-300NExtended L... -

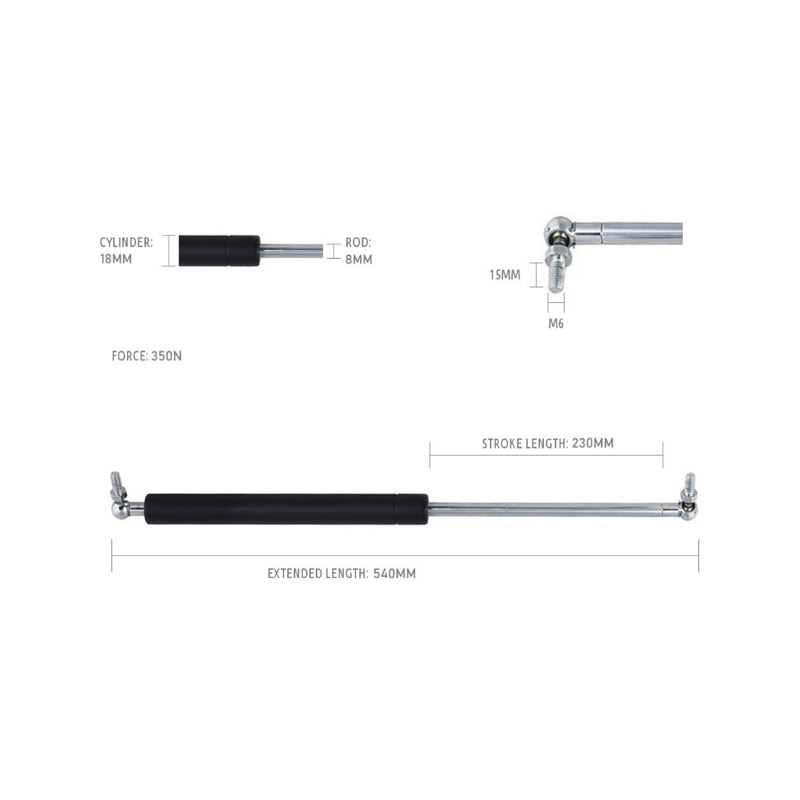

Gas Strut 230-540/350N GS230-540-350NExtended L...

Gas Strut 230-540/350N GS230-540-350NExtended L... -

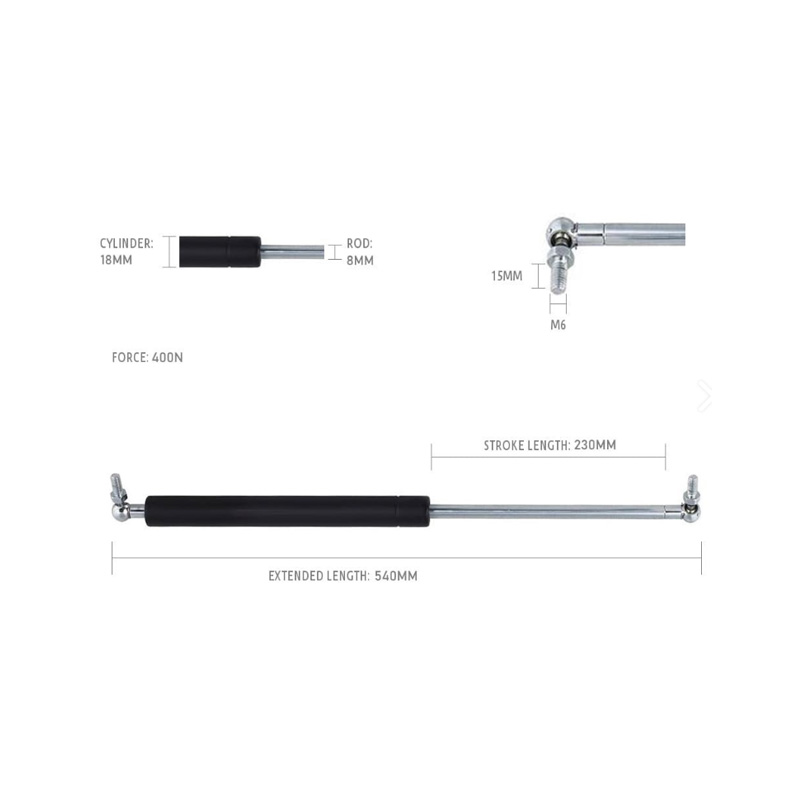

Gas Strut 230-540/400N GS230-540-400NExtended L...

Gas Strut 230-540/400N GS230-540-400NExtended L...

-

- Ladder Rack >

- Canopy Ladder >

- Toolbox Cargo Cage >

- Toolbox Rear Gate >

-

Fuel Gas Tool Holder

>

-

600 x 230 x 290mm Aluminium Tool Storage Handle Holder Heavy Duty ToteThickness:...

600 x 230 x 290mm Aluminium Tool Storage Handle Holder Heavy Duty ToteThickness:... -

320 x 320 x 320mm Aluminium Checker Camping Camper 4x4 Ute Truck Trailer Gas Bottle HolderSize Lengt...

320 x 320 x 320mm Aluminium Checker Camping Camper 4x4 Ute Truck Trailer Gas Bottle HolderSize Lengt... -

450 x 230 x 300mm Aluminium Checker Camping Camper 4x4 Ute Truck Acetylene Oxy Gas Bottle Holder with DividerThickness:...

450 x 230 x 300mm Aluminium Checker Camping Camper 4x4 Ute Truck Acetylene Oxy Gas Bottle Holder with DividerThickness:... -

450 x 230 x 380mm Aluminium Camping 4x4 Ute Truck Acetylene Oxy Gas Bottle Holder with DividerThickness:...

450 x 230 x 380mm Aluminium Camping 4x4 Ute Truck Acetylene Oxy Gas Bottle Holder with DividerThickness:... -

450 x 230 x 300mm Aluminium Checker Camping Camper 4x4 Ute Truck Acetylene Oxy Gas Bottle HolderThickness:...

450 x 230 x 300mm Aluminium Checker Camping Camper 4x4 Ute Truck Acetylene Oxy Gas Bottle HolderThickness:... -

450 x 230 x 380mm Aluminium Camping 4x4 Ute Truck Acetylene Oxy Gas Bottle HolderSize Lengt...

450 x 230 x 380mm Aluminium Camping 4x4 Ute Truck Acetylene Oxy Gas Bottle HolderSize Lengt... -

400 x 220 x 500mm Checker Aluminium Ute Camping Camper Jerry Can Bottle Holder Pad lockable Tool BoxThickness:...

400 x 220 x 500mm Checker Aluminium Ute Camping Camper Jerry Can Bottle Holder Pad lockable Tool BoxThickness:... -

335 x 285 x 400mm 4.5kg Aluminium Gas Bottle HolderThickness:...

335 x 285 x 400mm 4.5kg Aluminium Gas Bottle HolderThickness:... -

361 x 196 x 303mm Flat Aluminium Ute Camping Camper Jerry Can Bottle Holder Tool BoxThickness:...

361 x 196 x 303mm Flat Aluminium Ute Camping Camper Jerry Can Bottle Holder Tool BoxThickness:...

-

- Jack off Legs >

-

Trailers Accessories

>

- About

- News

- Contact

Web Menu

- Home

- TRAILERS

- TOOLBOXES

- ACCESSORIES

- About

- News

- Contact Us

Product Search

Classification and Advantages of Aluminum Toolboxes

Aluminum toolboxes factory are essential storage solutions widely used across industries like construction, automotive repair, and general household maintenance. Known for their durability, lightweight nature, and corrosion resistance, aluminum toolboxes offer many benefits compared to other materials like plastic or steel. These toolboxes come in various types and sizes, designed to meet the needs of different users, from professionals to DIY enthusiasts.

Durability and Strength

One of the notable advantages of aluminum toolboxes is their exceptional durability. Aluminum, being a lightweight yet strong metal, is resistant to impact, corrosion, and wear, making it an ideal material for tool storage. Aluminum toolboxes are often used in harsh environments where tools need to be protected from moisture, dust, and rough handling.

Unlike plastic toolboxes, which can crack or break under pressure, aluminum toolboxes are much more resilient. They can withstand drops, rough transport, and environmental factors such as temperatures and UV exposure. Moreover, aluminum does not rust, which is a major concern with steel toolboxes, especially when exposed to moisture. This resistance to rust and corrosion makes aluminum toolboxes highly suitable for outdoor use and in wet conditions, ensuring that the tools inside remain safe and dry.

Aluminum toolboxes are also capable of carrying heavier loads compared to plastic alternatives, which ensures that the tools and equipment stored inside are secure. This robust nature of aluminum helps prolong the lifespan of the toolbox itself, making it a cost-effective long-term investment.

Portability and Weight

Portability is another key benefit of aluminum toolboxes. Aluminum is a much lighter material than steel, which makes these toolboxes easier to transport without compromising on strength. Whether you're a tradesperson carrying tools to different job sites or a homeowner needing to move your toolbox from the garage to the workshop, aluminum toolboxes provide an efficient, lightweight storage solution.

The lighter weight of aluminum toolboxes does not sacrifice their structural integrity. While they are much easier to carry or load into a vehicle, they maintain enough sturdiness to carry a substantial amount of weight. Many aluminum toolboxes come with handles or even wheels, further enhancing their portability, especially when transporting heavy tools.

For professionals who are constantly on the move, such as mechanics or construction workers, the portability of aluminum toolboxes is invaluable. Being able to quickly move a toolbox from one location to another without exerting much physical effort can significantly improve work efficiency.

Design and Customization

Aluminum toolboxes are known for their sleek and functional design. They come in various sizes and configurations, including single, double, and multi-compartment boxes, to suit a wide range of needs. Whether you're storing a small set of hand tools or a more extensive collection of power tools, there is an aluminum toolbox that can accommodate your requirements.

The design of these toolboxes often includes features like removable trays, foam padding, and adjustable dividers, allowing users to organize their tools for accessibility and convenience. Some high-end models are even designed with integrated locks for added security, ensuring that the tools are protected from theft or unauthorized access.

Another significant advantage of aluminum toolboxes is their ability to be customized. For businesses, the external surface of an aluminum toolbox can be branded with logos or company names through engraving, printing, or adhesive decals. This customization option makes aluminum toolboxes popular in industries where professional appearance and brand identity matter, such as for service technicians or field engineers.

Safety and Protection

Aluminum toolboxes provide good protection for both the tools inside and the individuals using them. The sturdy construction of these toolboxes ensures that tools are securely stored, preventing damage from impacts or abrasions. Since aluminum toolboxes are typically equipped with durable latches or locking mechanisms, they help keep tools secure and organized, reducing the risk of accidents caused by disorganized or misplaced equipment.

In addition to protecting the tools themselves, aluminum toolboxes also help keep their contents safe from environmental hazards. With aluminum's resistance to corrosion, tools are protected from moisture and rust that could potentially damage their components. This is particularly important when storing tools for long periods or when they are used in environments where moisture is prevalent, such as marine or outdoor construction work.

Many aluminum toolboxes are designed with safety features like reinforced corners, non-slip feet, and weatherproof seals. These features enhance the toolbox's durability and provide added protection against accidental damage. For users working in high-risk areas, such as construction sites or industrial environments, having a toolbox that ensures the safety of both the tools and the worker is critical.

Post a comment

- GET A QUOTE

- PRODUCTS

- TRAILERS

- TOOLBOXES

- ACCESSORIES

- CONTACT US

-

-

+86-0579-82795522

+86-0579-82795522 -

+86-13362901332(Jack)

+86-13362901332(Jack)

-

-

No. 1533 Huaxi Road, Jinhua City, Zhejiang Province, China

No. 1533 Huaxi Road, Jinhua City, Zhejiang Province, China

-

- MOBILE SITE

English

English  Español

Español  русский

русский