- Home

-

Trailers

- Box Trailers >

-

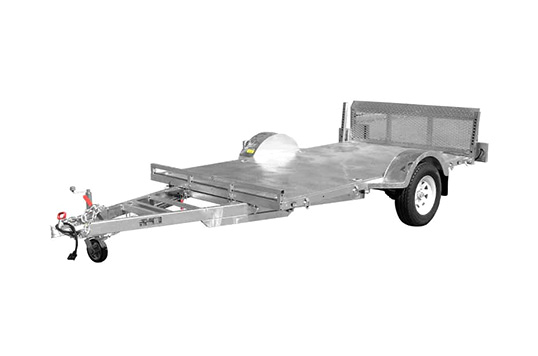

Flat Top/Flat Bed Trailers

>

- Single Axle Flatbed Trailers >

-

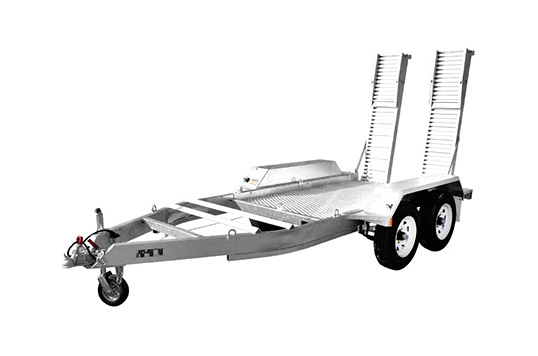

Tandem Axle Flatbed Trailers

>

-

8×5ft ATM 1990KG Flat Top /Flat Bed TrailerTrail...

8×5ft ATM 1990KG Flat Top /Flat Bed TrailerTrail... -

10×6.3ft ATM 2800KG Flat Top /Flat Bed Tandem TrailerTrail...

10×6.3ft ATM 2800KG Flat Top /Flat Bed Tandem TrailerTrail... -

10×6ft ATM 3500KG Flat Top /Flat Bed Hydraulic Tipper TrailerTrail...

10×6ft ATM 3500KG Flat Top /Flat Bed Hydraulic Tipper TrailerTrail... -

12×7ft ATM 3500KG Flat Top /Flat Bed Tandem TrailerTrail...

12×7ft ATM 3500KG Flat Top /Flat Bed Tandem TrailerTrail... -

14×7ft 3500KG ATM Flat Bed Tandem TrailerTrail...

14×7ft 3500KG ATM Flat Bed Tandem TrailerTrail... -

12×7ft ATM 3500KG Tandem Flatbed Hydraulic Tipper TrailerTrail...

12×7ft ATM 3500KG Tandem Flatbed Hydraulic Tipper TrailerTrail...

-

- Tri Axle Flatbed Trailers >

- Hydraulic Tippers >

- Cattle/ Livestock Trailers >

-

Boat, Kayak & Jet Ski Trailers

>

-

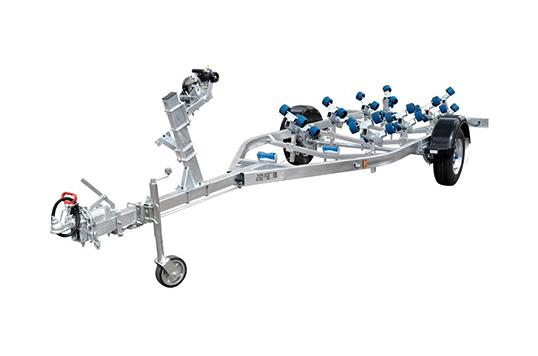

Single Axle Rollers Boat Trailer

>

-

4100 Series 750KG ATM Single Axle Rollers Boat TrailerTrail...

4100 Series 750KG ATM Single Axle Rollers Boat TrailerTrail... -

4500 Series 750KG ATM Single Axle Rollers Boat TrailerTrail...

4500 Series 750KG ATM Single Axle Rollers Boat TrailerTrail... -

4900 Series 1200KG ATM Single Axle Rollers Boat TrailerTrail...

4900 Series 1200KG ATM Single Axle Rollers Boat TrailerTrail... -

5700 Series 1500KG ATM Single Axle Rollers Boat TrailerTrail...

5700 Series 1500KG ATM Single Axle Rollers Boat TrailerTrail... -

6300 Series 1500KG ATM Single Axle Rollers Boat TrailerTrail...

6300 Series 1500KG ATM Single Axle Rollers Boat TrailerTrail...

-

- Single Axle Skid Boat Trailer >

- Tandem Axle Rollers Boat Trailer >

- Kayak & Canoe Trailer >

-

Single Axle Rollers Boat Trailer

>

- Motorcycles, ATV & Buggy Trailers >

- Car & Plant Trailers >

- Gardening & Mowing Trailers >

-

Builders/Tradesman Trailers

>

-

Single Axle Fully Enclosed & Luggage Trailer

>

-

6×4ft Small Tradesman/ Builders TrailerTrail...

6×4ft Small Tradesman/ Builders TrailerTrail... -

7×4ft Tradesman/ Builders TrailerTrail...

7×4ft Tradesman/ Builders TrailerTrail... -

7×5ft Tradesman/ Builders Trailer with Aluminium CanopyTrail...

7×5ft Tradesman/ Builders Trailer with Aluminium CanopyTrail... -

8×5ft Durable Tradesman/ Builders TrailerTrail...

8×5ft Durable Tradesman/ Builders TrailerTrail... -

8×6ft ATM 750KG Tradesman/ Builders TrailerTrail...

8×6ft ATM 750KG Tradesman/ Builders TrailerTrail... -

7×5ft Heavy Duty Tradesman/ Builders TrailerTrail...

7×5ft Heavy Duty Tradesman/ Builders TrailerTrail... -

8×5ft Heavy Duty ATM 1400KG Tradesman/ Builders TrailerTrail...

8×5ft Heavy Duty ATM 1400KG Tradesman/ Builders TrailerTrail... -

8×6ft Heavy Duty Enclosed Tradesman/ Builders TrailerTrail...

8×6ft Heavy Duty Enclosed Tradesman/ Builders TrailerTrail...

-

-

Tandem Axle Builders/Tradesman Trailer

>

-

8×5ft Dual Axle Builders/Tradesman TrailerTrail...

8×5ft Dual Axle Builders/Tradesman TrailerTrail... -

10×5ft Tandem Builders/Tradesman TrailerTrail...

10×5ft Tandem Builders/Tradesman TrailerTrail... -

10×6ft Tandem Builders/Tradesman TrailerTrail...

10×6ft Tandem Builders/Tradesman TrailerTrail... -

8×5ft Tandem Axle Tradesman/ Builders TrailerTrail...

8×5ft Tandem Axle Tradesman/ Builders TrailerTrail... -

10×5ft Tandem Tradesman/ Builders TrailerTrail...

10×5ft Tandem Tradesman/ Builders TrailerTrail... -

10×6ft Tandem Tradesman/ Builders Trailer with Aluminium CanopyTrail...

10×6ft Tandem Tradesman/ Builders Trailer with Aluminium CanopyTrail...

-

-

Single Axle Fully Enclosed & Luggage Trailer

>

- Enclosed/Luggage Trailers >

-

Toolboxes

-

Under Tray Toolboxes

>

-

Ute Under Tray Toolboxes

>

-

580 x 230 x 400mm Aluminium Checker Ute Toolbox Truck Storage Under Body Tray Storage Strap Tool BoxThickness:...

580 x 230 x 400mm Aluminium Checker Ute Toolbox Truck Storage Under Body Tray Storage Strap Tool BoxThickness:... -

600 x 200 x 400mm Aluminium 20L Ute Camping Under Tray Body Box Storage Water TankThickness:...

600 x 200 x 400mm Aluminium 20L Ute Camping Under Tray Body Box Storage Water TankThickness:... -

600 x 230 x 400mm Aluminium Pair Ute Toolbox Truck Storage Under Body Tray Storage Strap Tool Box Off Road TapperThickness:...

600 x 230 x 400mm Aluminium Pair Ute Toolbox Truck Storage Under Body Tray Storage Strap Tool Box Off Road TapperThickness:... -

600 x 230 x 400mm Aluminium Set Pair Ute Toolbox Truck Storage Under Body Tray Storage Strap Tool Box Off Road TapperThickness:...

600 x 230 x 400mm Aluminium Set Pair Ute Toolbox Truck Storage Under Body Tray Storage Strap Tool Box Off Road TapperThickness:... -

750 x 230 x 400mm Aluminium SET PAIR Ute Toolbox Truck Storage Under Body Tray Storage Strap Tool Box Off Road TapperThickness:...

750 x 230 x 400mm Aluminium SET PAIR Ute Toolbox Truck Storage Under Body Tray Storage Strap Tool Box Off Road TapperThickness:... -

750 x 230 x 400mm Aluminium SET PAIR Ute Toolbox Truck Storage Under Body Tray Storage Strap Tool Box Off Road TapperThickness:...

750 x 230 x 400mm Aluminium SET PAIR Ute Toolbox Truck Storage Under Body Tray Storage Strap Tool Box Off Road TapperThickness:... -

700 x 260 x 400mm (LIMITED EDITION) Under Tray Toolbox TapperedThickness:...

700 x 260 x 400mm (LIMITED EDITION) Under Tray Toolbox TapperedThickness:... -

940 x 230 x 400mm Aluminium SET PAIR Ute Toolbox Truck Storage Under Body Tray Storage Strap Tool Box Off Road TapperThickness:...

940 x 230 x 400mm Aluminium SET PAIR Ute Toolbox Truck Storage Under Body Tray Storage Strap Tool Box Off Road TapperThickness:... -

940 x 230 x 400mm Aluminium SET PAIR Ute Toolbox Truck Storage Under Body Tray Storage Strap Tool Box Off Road TapperThickness:...

940 x 230 x 400mm Aluminium SET PAIR Ute Toolbox Truck Storage Under Body Tray Storage Strap Tool Box Off Road TapperThickness:... -

900 x 260 x 400mm (LIMITED EDITION) Under Tray Toolbox TapperedThickness:...

900 x 260 x 400mm (LIMITED EDITION) Under Tray Toolbox TapperedThickness:...

-

-

Truck Under Tray Boxes

>

-

600 x 450 x 450mm Aluminium Checker Under Tray Body Tool box Truck Storage ToolboxThickness:...

600 x 450 x 450mm Aluminium Checker Under Tray Body Tool box Truck Storage ToolboxThickness:... -

600 x 450 x 450mm Flat Aluminium Under Tray Body Tool box Truck Storage ToolboxThickness:...

600 x 450 x 450mm Flat Aluminium Under Tray Body Tool box Truck Storage ToolboxThickness:... -

900 x 450 x 450mm Flat Aluminium Under Tray Body Tool box Truck Storage ToolboxThickness:...

900 x 450 x 450mm Flat Aluminium Under Tray Body Tool box Truck Storage ToolboxThickness:... -

1000 x 450 x 450mm Flat Aluminium Under Tray Body Tool box Truck Storage ToolboxThickness:...

1000 x 450 x 450mm Flat Aluminium Under Tray Body Tool box Truck Storage ToolboxThickness:... -

1200 x 450 x 450mm Flat Aluminium Under Tray Body Tool box Truck Storage ToolboxThickness:...

1200 x 450 x 450mm Flat Aluminium Under Tray Body Tool box Truck Storage ToolboxThickness:... -

600 x 500 x 500mm Black Aluminium Under Tray Slide Drawer Body Tool box Truck Storage ToolboxThickness:...

600 x 500 x 500mm Black Aluminium Under Tray Slide Drawer Body Tool box Truck Storage ToolboxThickness:... -

900 x 500 x 500mm Raw Flat Aluminium Under Tray Slide Drawer Body Tool box Truck Storage ToolboxThickness:...

900 x 500 x 500mm Raw Flat Aluminium Under Tray Slide Drawer Body Tool box Truck Storage ToolboxThickness:... -

1200 x 500 x 500mm Black Aluminium Under Tray Slide Drawer Body Tool box Truck Storage ToolboxThickness:...

1200 x 500 x 500mm Black Aluminium Under Tray Slide Drawer Body Tool box Truck Storage ToolboxThickness:...

-

-

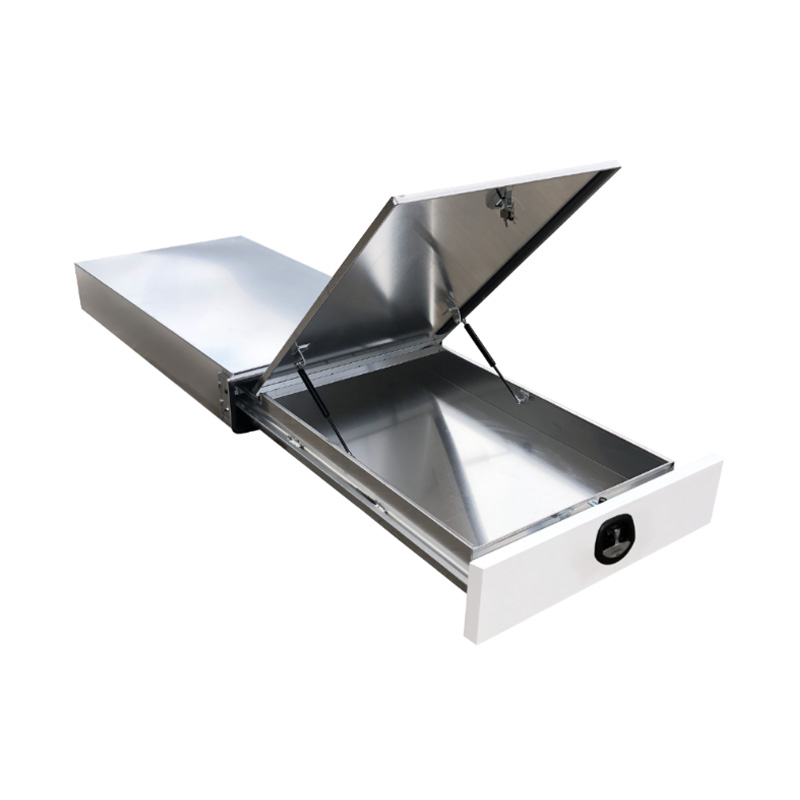

Trundle-Trays

>

-

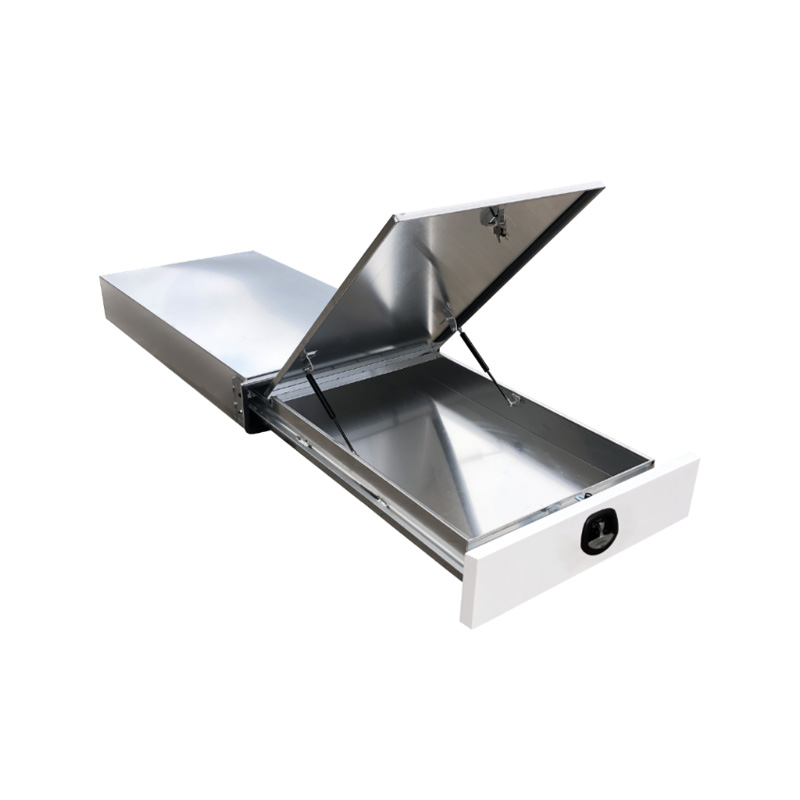

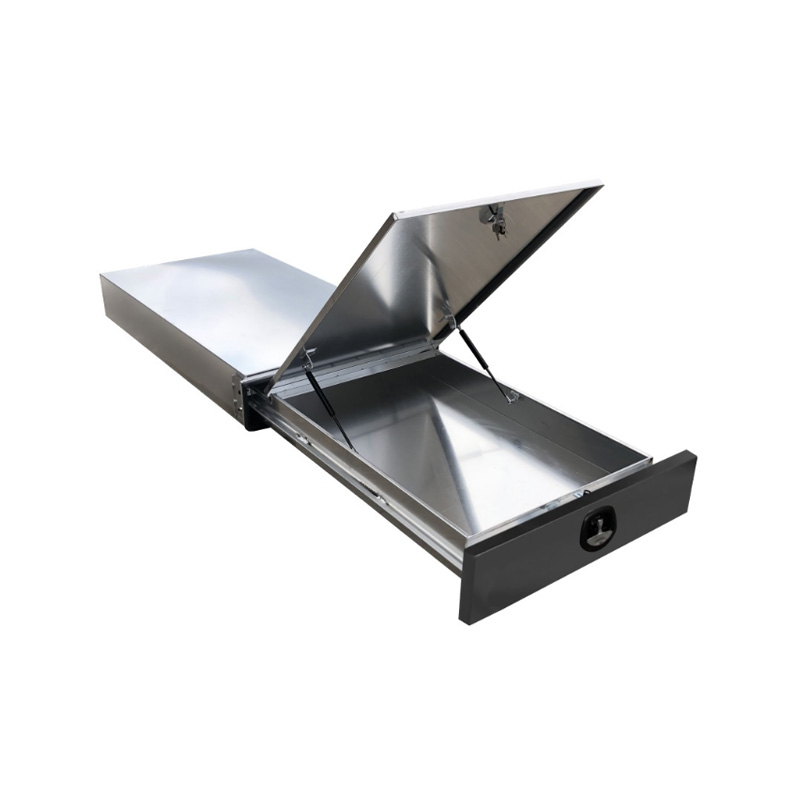

1.4m Aluminium Ute Tool box Under Tray Toolbox Trundle Roller Tray Slide Out Drawer Toolbox Benchtop LidThickness:...

1.4m Aluminium Ute Tool box Under Tray Toolbox Trundle Roller Tray Slide Out Drawer Toolbox Benchtop LidThickness:... -

1.6m Aluminium Ute Tool box Under Tray Toolbox Trundle Roller Tray Slide Out Drawer Toolbox Benchtop LidThickness:...

1.6m Aluminium Ute Tool box Under Tray Toolbox Trundle Roller Tray Slide Out Drawer Toolbox Benchtop LidThickness:... -

1.7m Aluminium Ute Tool box Under Tray Toolbox Trundle Roller Tray Slide Out Drawer Toolbox Benchtop LidThickness:...

1.7m Aluminium Ute Tool box Under Tray Toolbox Trundle Roller Tray Slide Out Drawer Toolbox Benchtop LidThickness:...

-

- Under Tray Water Tanks >

-

Ute Under Tray Toolboxes

>

-

Top Opening Toolboxes

>

-

Rectangle Ute Toolbox

>

-

900 x 400 x 400mm Aluminium Checker Top Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

900 x 400 x 400mm Aluminium Checker Top Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:... -

1220 x 400 x 350mm Aluminium Top Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

1220 x 400 x 350mm Aluminium Top Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:... -

1220 x 500 x 500mm Aluminium Top Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & Canopy 1255Thickness:...

1220 x 500 x 500mm Aluminium Top Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & Canopy 1255Thickness:... -

1500 x 500 x 450mm Aluminium Checker Top Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

1500 x 500 x 450mm Aluminium Checker Top Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:... -

1200 x 600 x 500mm Aluminium Top Chest Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & Canopy(Chest Style)Thickness:...

1200 x 600 x 500mm Aluminium Top Chest Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & Canopy(Chest Style)Thickness:... -

1400 x 600 x 500mm Aluminium Top Chest Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

1400 x 600 x 500mm Aluminium Top Chest Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:... -

1700 x 600 x 500mm Aluminium Top Chest Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

1700 x 600 x 500mm Aluminium Top Chest Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:... -

1200 x 600 x 700mm Aluminium Checker Tool Box Ute Truck Fridge Trailer 3/4 Angle Storage ToolboxThickness:...

1200 x 600 x 700mm Aluminium Checker Tool Box Ute Truck Fridge Trailer 3/4 Angle Storage ToolboxThickness:... -

1400 x 600 x 700mm Aluminium Checker Tool Box Ute Truck Fridge Trailer 3/4 Angle Storage ToolboxThickness:...

1400 x 600 x 700mm Aluminium Checker Tool Box Ute Truck Fridge Trailer 3/4 Angle Storage ToolboxThickness:... -

1500 x 400 x 400mm Aluminium Checker 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:...

1500 x 400 x 400mm Aluminium Checker 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:... -

1500 x 500 x 500mm Raw Flat Aluminium 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:...

1500 x 500 x 500mm Raw Flat Aluminium 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:... -

2000 x 500 x 500mm Aluminium 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:...

2000 x 500 x 500mm Aluminium 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:...

-

-

Chest Style Ute Toolbox

>

-

1500 x 500 x 450mm Aluminium Checker Top Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

1500 x 500 x 450mm Aluminium Checker Top Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:... -

1200 x 600 x 500mm Aluminium Top Chest Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & Canopy(Chest Style)Thickness:...

1200 x 600 x 500mm Aluminium Top Chest Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & Canopy(Chest Style)Thickness:... -

1400 x 600 x 500mm Aluminium Top Chest Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

1400 x 600 x 500mm Aluminium Top Chest Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

-

- Tub Liner Ute Toolbox >

- Job Site Toolbox >

-

Camper Ute Toolbox

>

-

1500 x 400 x 400mm Aluminium Checker 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:...

1500 x 400 x 400mm Aluminium Checker 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:... -

1500 x 500 x 500mm Raw Flat Aluminium 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:...

1500 x 500 x 500mm Raw Flat Aluminium 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:... -

2000 x 500 x 500mm Aluminium 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:...

2000 x 500 x 500mm Aluminium 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:... -

610 x 330 x 540mm Aluminium Checker Ute Toolbox Trailer Camper Caravan Generator Tool Box for Honda 2kvaThickness:...

610 x 330 x 540mm Aluminium Checker Ute Toolbox Trailer Camper Caravan Generator Tool Box for Honda 2kvaThickness:... -

700 x 450 x 650mm Aluminium Checker Ute Toolbox Trailer Camper Caravan Generator Tool BoxThickness:...

700 x 450 x 650mm Aluminium Checker Ute Toolbox Trailer Camper Caravan Generator Tool BoxThickness:... -

760 x 500 x 560mm Aluminium Checker Ute Toolbox Trailer Camper Caravan Generator Tool BoxThickness:...

760 x 500 x 560mm Aluminium Checker Ute Toolbox Trailer Camper Caravan Generator Tool BoxThickness:... -

1700 x 550 x 610mm Black Aluminium Checker Ute Truck Tool Box Fridge Slide & Webber BBQ Slide Camper ToolboxThickness:...

1700 x 550 x 610mm Black Aluminium Checker Ute Truck Tool Box Fridge Slide & Webber BBQ Slide Camper ToolboxThickness:... -

2200 x 550 x 550mm Aluminium 3 Lid Slides BBQ Generator Camper ToolboxThickness:...

2200 x 550 x 550mm Aluminium 3 Lid Slides BBQ Generator Camper ToolboxThickness:... -

1400 x 550 x 800mm Black Aluminium Checker Ute Toolbox Webber BBQ & Fridge Slide Camper Caravan Canopy Tool BoxThickness:...

1400 x 550 x 800mm Black Aluminium Checker Ute Toolbox Webber BBQ & Fridge Slide Camper Caravan Canopy Tool BoxThickness:... -

1700 x 550 x 800mm Black Aluminium Checker Ute Toolbox Webber BBQ & Fridge Slide Camper Caravan Canopy Tool BoxThickness:...

1700 x 550 x 800mm Black Aluminium Checker Ute Toolbox Webber BBQ & Fridge Slide Camper Caravan Canopy Tool BoxThickness:... -

2000 x 550 x 800mm Black Aluminium Checker Ute Toolbox Webber BBQ & Fridge Slide Camper Caravan Canopy Tool BoxThickness:...

2000 x 550 x 800mm Black Aluminium Checker Ute Toolbox Webber BBQ & Fridge Slide Camper Caravan Canopy Tool BoxThickness:...

-

-

Cross Deck Gullwing

>

-

1500 x 500 x 500mm Raw Flat Aluminium 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:...

1500 x 500 x 500mm Raw Flat Aluminium 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:... -

2000 x 500 x 500mm Aluminium 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:...

2000 x 500 x 500mm Aluminium 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:... -

1770 x 600 x 500mm Aluminium Checker Sloped Top Gullwing Cross Deck Dual 2 Lid Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

1770 x 600 x 500mm Aluminium Checker Sloped Top Gullwing Cross Deck Dual 2 Lid Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:... -

1770 x 600 x 500mm Aluminium Checker Flat Top Gullwing Cross Deck Dual 2 Lid Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

1770 x 600 x 500mm Aluminium Checker Flat Top Gullwing Cross Deck Dual 2 Lid Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

-

-

Rectangle Ute Toolbox

>

-

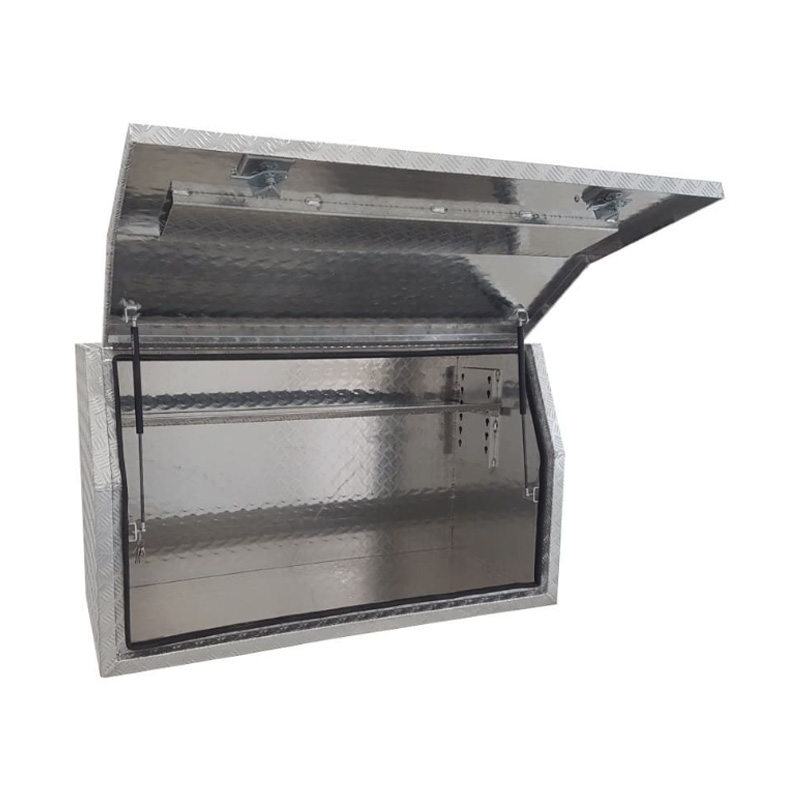

Side Opening Toolboxes

>

-

Half Lid Opening Ute Toolbox

>

-

1200 x 600 x 700mm Aluminium Checker Tool Box Ute Truck Fridge Trailer 3/4 Angle Storage ToolboxThickness:...

1200 x 600 x 700mm Aluminium Checker Tool Box Ute Truck Fridge Trailer 3/4 Angle Storage ToolboxThickness:... -

1400 x 600 x 700mm Aluminium Checker Tool Box Ute Truck Fridge Trailer 3/4 Angle Storage ToolboxThickness:...

1400 x 600 x 700mm Aluminium Checker Tool Box Ute Truck Fridge Trailer 3/4 Angle Storage ToolboxThickness:... -

1400 x 500 x 700mm Aluminium Checker 3/4 Half Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingxThickness:...

1400 x 500 x 700mm Aluminium Checker 3/4 Half Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingxThickness:... -

1700 x 500 x 700mm Aluminium Checker 3/4 Half Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1700 x 500 x 700mm Aluminium Checker 3/4 Half Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1400 x 600 x 820mm Aluminium Checker Full or Half Side Multi Lid Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1400 x 600 x 820mm Aluminium Checker Full or Half Side Multi Lid Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1700 x 600 x 820mm Aluminium Full or Half Side Multi Lid Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1700 x 600 x 820mm Aluminium Full or Half Side Multi Lid Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

900 x 600 x 820mm Aluminium Checker 3/4 Half Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

900 x 600 x 820mm Aluminium Checker 3/4 Half Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1200 x 600 x 820mm Aluminium Checker 3/4 Half Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1200 x 600 x 820mm Aluminium Checker 3/4 Half Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1400 x 600 x 820mm Aluminium 3/4 Half Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1400 x 600 x 820mm Aluminium 3/4 Half Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1700 x 600 x 820mm Aluminium 3/4 Half Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1700 x 600 x 820mm Aluminium 3/4 Half Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

2100 x 600 x 820mm Aluminium 3/4 Half Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

2100 x 600 x 820mm Aluminium 3/4 Half Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

-

-

Half Lid Ute Toolbox With Drawers

>

-

1500 x 600 x 820mm Aluminium Checker 3/4 Half Side Opening 2 Drawer Slide Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1500 x 600 x 820mm Aluminium Checker 3/4 Half Side Opening 2 Drawer Slide Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1400 x 600 x 820mm Aluminium 3/4 Half Side Opening 2 Drawer Slide Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1400 x 600 x 820mm Aluminium 3/4 Half Side Opening 2 Drawer Slide Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1700 x 600 x 820mm Aluminium 3/4 Half Side Opening 3 Drawer Slide Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1700 x 600 x 820mm Aluminium 3/4 Half Side Opening 3 Drawer Slide Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

2100 x 600 x 820mm Aluminium 3/4 Half Side Opening 3 Drawer Slide Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

2100 x 600 x 820mm Aluminium 3/4 Half Side Opening 3 Drawer Slide Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

-

-

Full Lid Opening Ute Toolbox

>

-

1400 x 500 x 700mm Aluminium Checker Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1400 x 500 x 700mm Aluminium Checker Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1700 x 500 x 700mm Aluminium Checker Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1700 x 500 x 700mm Aluminium Checker Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1400 x 600 x 820mm Aluminium Checker Full or Half Side Multi Lid Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1400 x 600 x 820mm Aluminium Checker Full or Half Side Multi Lid Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1400 x 600 x 820mm Aluminium Checker Full Side Opening Square Edge Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1400 x 600 x 820mm Aluminium Checker Full Side Opening Square Edge Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1700 x 600 x 820mm Aluminium Full or Half Side Multi Lid Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1700 x 600 x 820mm Aluminium Full or Half Side Multi Lid Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1700 x 600 x 820mm Aluminium Checker Full Side Opening Square Edge Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1700 x 600 x 820mm Aluminium Checker Full Side Opening Square Edge Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

900 x 600 x 820mm Aluminium Checker Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

900 x 600 x 820mm Aluminium Checker Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1000 x 530 x 820mm Aluminium Checker Side Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

1000 x 530 x 820mm Aluminium Checker Side Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:... -

1200 x 600 x 820mm Aluminium Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1200 x 600 x 820mm Aluminium Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1400 x 530 x 820mm Aluminium Checker Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1400 x 530 x 820mm Aluminium Checker Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1400 x 600 x 820mm Aluminium Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1400 x 600 x 820mm Aluminium Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1500 x 530 x 820mm Aluminium Checker Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1500 x 530 x 820mm Aluminium Checker Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1600 x 530 x 820mm Aluminium Checker Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1600 x 530 x 820mm Aluminium Checker Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1600 x 600 x 820mm Aluminium Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1600 x 600 x 820mm Aluminium Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1700 x 530 x 820mm Aluminium Checker Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1700 x 530 x 820mm Aluminium Checker Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1700 x 600 x 820mm Aluminium Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1700 x 600 x 820mm Aluminium Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1800 x 530 x 820mm Aluminium Checker Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1800 x 530 x 820mm Aluminium Checker Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1900 x 530 x 820mm Aluminium Checker Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1900 x 530 x 820mm Aluminium Checker Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

2100 x 600 x 820mm Aluminium Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

2100 x 600 x 820mm Aluminium Full Side Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1900 x 600 x 820mm Aluminium Full Side Opening Truck Tool Box HIGH Side Trailer Toolbox ShelvingThickness:...

1900 x 600 x 820mm Aluminium Full Side Opening Truck Tool Box HIGH Side Trailer Toolbox ShelvingThickness:...

-

-

Full Lid Ute Toolbox With Drawers

>

-

1400 x 600 x 820mm Aluminium Full Side Opening 2 Drawer Slide Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1400 x 600 x 820mm Aluminium Full Side Opening 2 Drawer Slide Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1400 x 600 x 820mm Aluminium Full Side Opening 4 Drawer Slide Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1400 x 600 x 820mm Aluminium Full Side Opening 4 Drawer Slide Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1700 x 600 x 820mm Aluminium Full Side Opening 2 Drawer Slide Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1700 x 600 x 820mm Aluminium Full Side Opening 2 Drawer Slide Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1700 x 600 x 820mm Aluminium Full Side Opening 4 Drawer Slide Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1700 x 600 x 820mm Aluminium Full Side Opening 4 Drawer Slide Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

-

-

Multi-Lid Ute Toolbox

>

-

1770 x 600 x 500mm Aluminium Checker Sloped Top Gullwing Cross Deck Dual 2 Lid Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

1770 x 600 x 500mm Aluminium Checker Sloped Top Gullwing Cross Deck Dual 2 Lid Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:... -

1770 x 600 x 500mm Aluminium Checker Flat Top Gullwing Cross Deck Dual 2 Lid Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

1770 x 600 x 500mm Aluminium Checker Flat Top Gullwing Cross Deck Dual 2 Lid Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:... -

1400 x 600 x 820mm Aluminium Checker Full or Half Side Multi Lid Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1400 x 600 x 820mm Aluminium Checker Full or Half Side Multi Lid Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1700 x 600 x 820mm Aluminium Full or Half Side Multi Lid Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1700 x 600 x 820mm Aluminium Full or Half Side Multi Lid Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1400 x 600 x 820mm Aluminium Checker Full or Half Side Multi Lid Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1400 x 600 x 820mm Aluminium Checker Full or Half Side Multi Lid Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1700 x 600 x 820mm Aluminium Full or Half Side Multi Lid Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1700 x 600 x 820mm Aluminium Full or Half Side Multi Lid Opening Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

-

-

Half Lid Opening Ute Toolbox

>

-

Truck Toolboxes

>

-

Under Truck Tool Boxes

>

-

600 x 450 x 450mm Aluminium Checker Under Tray Body Tool box Truck Storage ToolboxThickness:...

600 x 450 x 450mm Aluminium Checker Under Tray Body Tool box Truck Storage ToolboxThickness:... -

600 x 450 x 450mm Flat Aluminium Under Tray Body Tool box Truck Storage ToolboxThickness:...

600 x 450 x 450mm Flat Aluminium Under Tray Body Tool box Truck Storage ToolboxThickness:... -

900 x 450 x 450mm Flat Aluminium Under Tray Body Tool box Truck Storage ToolboxThickness:...

900 x 450 x 450mm Flat Aluminium Under Tray Body Tool box Truck Storage ToolboxThickness:... -

1000 x 450 x 450mm Flat Aluminium Under Tray Body Tool box Truck Storage ToolboxThickness:...

1000 x 450 x 450mm Flat Aluminium Under Tray Body Tool box Truck Storage ToolboxThickness:... -

1200 x 450 x 450mm Flat Aluminium Under Tray Body Tool box Truck Storage ToolboxThickness:...

1200 x 450 x 450mm Flat Aluminium Under Tray Body Tool box Truck Storage ToolboxThickness:... -

600 x 500 x 500mm Black Aluminium Under Tray Slide Drawer Body Tool box Truck Storage ToolboxThickness:...

600 x 500 x 500mm Black Aluminium Under Tray Slide Drawer Body Tool box Truck Storage ToolboxThickness:... -

900 x 500 x 500mm Raw Flat Aluminium Under Tray Slide Drawer Body Tool box Truck Storage ToolboxThickness:...

900 x 500 x 500mm Raw Flat Aluminium Under Tray Slide Drawer Body Tool box Truck Storage ToolboxThickness:...

-

- Half Lid Truck Toolbox With Drawers >

-

Full Lid Opening Truck Toolbox

>

-

1400 x 600 x 1200mm Aluminium Full Side Opening Truck Tool Box HIGH Side Trailer Toolbox ShelvingThickness:...

1400 x 600 x 1200mm Aluminium Full Side Opening Truck Tool Box HIGH Side Trailer Toolbox ShelvingThickness:... -

1900 x 600 x 820mm Aluminium Full Side Opening Truck Tool Box HIGH Side Trailer Toolbox Shelving 1968SFD-CPThickness:...

1900 x 600 x 820mm Aluminium Full Side Opening Truck Tool Box HIGH Side Trailer Toolbox Shelving 1968SFD-CPThickness:... -

1900 x 600 x 1200mm Aluminium Checker Full Side Opening Truck Tool Box HIGH Side Trailer Toolbox ShelvingThickness:...

1900 x 600 x 1200mm Aluminium Checker Full Side Opening Truck Tool Box HIGH Side Trailer Toolbox ShelvingThickness:... -

1900 x 600 x 1200mm Checker PRO Full Side Truck Tool Box HIGH Side Toolbox Shelving ReinforcedThickness:...

1900 x 600 x 1200mm Checker PRO Full Side Truck Tool Box HIGH Side Toolbox Shelving ReinforcedThickness:... -

1900 x 600 x 1200mm Aluminium Flat PRO Full Side Truck Tool Box HIGH Side Toolbox Shelving ReinforcedThickness:...

1900 x 600 x 1200mm Aluminium Flat PRO Full Side Truck Tool Box HIGH Side Toolbox Shelving ReinforcedThickness:... -

1900 x 600 x 1200mm Aluminium 4 Drawer Full Side Truck Tool Box HIGH Side Trailer Toolbox ShelvingThickness:...

1900 x 600 x 1200mm Aluminium 4 Drawer Full Side Truck Tool Box HIGH Side Trailer Toolbox ShelvingThickness:... -

1400 x 600 x 820mm Aluminium Checker Full Side Opening Square Edge Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1400 x 600 x 820mm Aluminium Checker Full Side Opening Square Edge Ute Tool Box Truck Trailer Toolbox ShelvingThickness:... -

1700 x 600 x 820mm Aluminium Checker Full Side Opening Square Edge Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

1700 x 600 x 820mm Aluminium Checker Full Side Opening Square Edge Ute Tool Box Truck Trailer Toolbox ShelvingThickness:...

-

- Full Lid Truck Toolbox With Drawers >

-

Under Truck Tool Boxes

>

- Dog Boxes >

-

Toolbox Canopies

>

-

1770 x 600 x 500mm Aluminium Checker Sloped Top Gullwing Cross Deck Dual 2 Lid Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

1770 x 600 x 500mm Aluminium Checker Sloped Top Gullwing Cross Deck Dual 2 Lid Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:... -

1770 x 600 x 500mm Aluminium Checker Flat Top Gullwing Cross Deck Dual 2 Lid Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

1770 x 600 x 500mm Aluminium Checker Flat Top Gullwing Cross Deck Dual 2 Lid Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:... -

1600 x 700 x 820mm Aluminium Ute Truck Trailer Toolbox Canopy Gullwing 1678-CP-SLDThickness:...

1600 x 700 x 820mm Aluminium Ute Truck Trailer Toolbox Canopy Gullwing 1678-CP-SLDThickness:... -

1770 x 700 x 820mm Aluminium Ute Tool Box Truck Trailer Full Lid Part Canopy ToolboxThickness:...

1770 x 700 x 820mm Aluminium Ute Tool Box Truck Trailer Full Lid Part Canopy ToolboxThickness:... -

1770 x 800 x 820mm Flat Aluminium Ute Tool Box Truck Trailer Full Lid Part Canopy ToolboxThickness:...

1770 x 800 x 820mm Flat Aluminium Ute Tool Box Truck Trailer Full Lid Part Canopy ToolboxThickness:... -

1770 x 1200 x 820mm Aluminium Checker Full Side Part Canopy Tool Box Ute Truck Trailer Toolbox Storage Gullwing ShelvingThickness:...

1770 x 1200 x 820mm Aluminium Checker Full Side Part Canopy Tool Box Ute Truck Trailer Toolbox Storage Gullwing ShelvingThickness:...

-

-

Camper & Trailer Boxes

>

-

Trailer Boxes/Draw bar Boxes

>

-

900 x 400 x 400mm Aluminium Checker Top Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

900 x 400 x 400mm Aluminium Checker Top Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:... -

1220 x 400 x 350mm Aluminium Top Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

1220 x 400 x 350mm Aluminium Top Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:... -

1220 x 500 x 500mm Aluminium Top Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & Canopy 1255Thickness:...

1220 x 500 x 500mm Aluminium Top Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & Canopy 1255Thickness:... -

1500 x 500 x 450mm Aluminium Checker Top Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

1500 x 500 x 450mm Aluminium Checker Top Opening Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:... -

1200 x 600 x 700mm Aluminium Checker Tool Box Ute Truck Fridge Trailer 3/4 Angle Storage ToolboxThickness:...

1200 x 600 x 700mm Aluminium Checker Tool Box Ute Truck Fridge Trailer 3/4 Angle Storage ToolboxThickness:... -

1400 x 600 x 700mm Aluminium Checker Tool Box Ute Truck Fridge Trailer 3/4 Angle Storage ToolboxThickness:...

1400 x 600 x 700mm Aluminium Checker Tool Box Ute Truck Fridge Trailer 3/4 Angle Storage ToolboxThickness:... -

1500 x 400 x 400mm Aluminium Checker 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:...

1500 x 400 x 400mm Aluminium Checker 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:... -

1500 x 500 x 500mm Raw Flat Aluminium 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:...

1500 x 500 x 500mm Raw Flat Aluminium 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:... -

2000 x 500 x 500mm Aluminium 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:...

2000 x 500 x 500mm Aluminium 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:... -

1700 x 550 x 610mm Black Aluminium Checker Ute Truck Tool Box Fridge Slide & Webber BBQ Slide Camper ToolboxThickness:...

1700 x 550 x 610mm Black Aluminium Checker Ute Truck Tool Box Fridge Slide & Webber BBQ Slide Camper ToolboxThickness:... -

2200 x 550 x 550mm Aluminium 3 Lid Slides BBQ Generator Camper ToolboxThickness:...

2200 x 550 x 550mm Aluminium 3 Lid Slides BBQ Generator Camper ToolboxThickness:... -

1400 x 550 x 800mm Black Aluminium Checker Ute Toolbox Webber BBQ & Fridge Slide Camper Caravan Canopy Tool BoxThickness:...

1400 x 550 x 800mm Black Aluminium Checker Ute Toolbox Webber BBQ & Fridge Slide Camper Caravan Canopy Tool BoxThickness:... -

1700 x 550 x 800mm Black Aluminium Checker Ute Toolbox Webber BBQ & Fridge Slide Camper Caravan Canopy Tool BoxThickness:...

1700 x 550 x 800mm Black Aluminium Checker Ute Toolbox Webber BBQ & Fridge Slide Camper Caravan Canopy Tool BoxThickness:... -

2000 x 550 x 800mm Black Aluminium Checker Ute Toolbox Webber BBQ & Fridge Slide Camper Caravan Canopy Tool BoxThickness:...

2000 x 550 x 800mm Black Aluminium Checker Ute Toolbox Webber BBQ & Fridge Slide Camper Caravan Canopy Tool BoxThickness:... -

1770 x 600 x 500mm Aluminium Checker Sloped Top Gullwing Cross Deck Dual 2 Lid Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

1770 x 600 x 500mm Aluminium Checker Sloped Top Gullwing Cross Deck Dual 2 Lid Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:... -

1770 x 600 x 500mm Aluminium Checker Flat Top Gullwing Cross Deck Dual 2 Lid Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:...

1770 x 600 x 500mm Aluminium Checker Flat Top Gullwing Cross Deck Dual 2 Lid Ute Tool box 4 Your Truck Ute Trailer Toolbox & CanopyThickness:... -

860 x 460 x 460mm Aluminium Checker Toolbox Trailer Draw Bar Storage DrawBar Tool BoxThickness:...

860 x 460 x 460mm Aluminium Checker Toolbox Trailer Draw Bar Storage DrawBar Tool BoxThickness:... -

1200 x 500 x 500mm Aluminium Toolbox Trailer Draw Bar Storage DrawBar Tool BoxThickness:...

1200 x 500 x 500mm Aluminium Toolbox Trailer Draw Bar Storage DrawBar Tool BoxThickness:... -

1400 x 580 x 820mm Aluminium Checker Full Side Center Box Caravan Ute Tool Box Truck Cab Trailer ToolboxThickness:...

1400 x 580 x 820mm Aluminium Checker Full Side Center Box Caravan Ute Tool Box Truck Cab Trailer ToolboxThickness:... -

1700 x 580 x 820mm Aluminium Checker Full Side Center Box Caravan Ute Tool Box Truck Cab Trailer ToolboxThickness:...

1700 x 580 x 820mm Aluminium Checker Full Side Center Box Caravan Ute Tool Box Truck Cab Trailer ToolboxThickness:...

-

-

Caravan Boxes

>

-

1500 x 400 x 400mm Aluminium Checker 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:...

1500 x 400 x 400mm Aluminium Checker 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:... -

1500 x 500 x 500mm Raw Flat Aluminium 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:...

1500 x 500 x 500mm Raw Flat Aluminium 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:... -

2000 x 500 x 500mm Aluminium 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:...

2000 x 500 x 500mm Aluminium 3 Lid Ute Toolbox Trailer Camping Camper Caravan Truck Tool BoxThickness:... -

1700 x 550 x 610mm Black Aluminium Checker Ute Truck Tool Box Fridge Slide & Webber BBQ Slide Camper ToolboxThickness:...

1700 x 550 x 610mm Black Aluminium Checker Ute Truck Tool Box Fridge Slide & Webber BBQ Slide Camper ToolboxThickness:... -

2200 x 550 x 550mm Aluminium 3 Lid Slides BBQ Generator Camper ToolboxThickness:...

2200 x 550 x 550mm Aluminium 3 Lid Slides BBQ Generator Camper ToolboxThickness:... -

1400 x 550 x 800mm Black Aluminium Checker Ute Toolbox Webber BBQ & Fridge Slide Camper Caravan Canopy Tool BoxThickness:...

1400 x 550 x 800mm Black Aluminium Checker Ute Toolbox Webber BBQ & Fridge Slide Camper Caravan Canopy Tool BoxThickness:... -

1700 x 550 x 800mm Black Aluminium Checker Ute Toolbox Webber BBQ & Fridge Slide Camper Caravan Canopy Tool BoxThickness:...

1700 x 550 x 800mm Black Aluminium Checker Ute Toolbox Webber BBQ & Fridge Slide Camper Caravan Canopy Tool BoxThickness:... -

2000 x 550 x 800mm Black Aluminium Checker Ute Toolbox Webber BBQ & Fridge Slide Camper Caravan Canopy Tool BoxThickness:...

2000 x 550 x 800mm Black Aluminium Checker Ute Toolbox Webber BBQ & Fridge Slide Camper Caravan Canopy Tool BoxThickness:... -

1600 x 700 x 820mm Aluminium Ute Truck Trailer Toolbox Canopy Gullwing 1678-CP-SLDThickness:...

1600 x 700 x 820mm Aluminium Ute Truck Trailer Toolbox Canopy Gullwing 1678-CP-SLDThickness:...

-

-

Generator Boxes

>

-

610 x 330 x 540mm Aluminium Checker Ute Toolbox Trailer Camper Caravan Generator Tool Box for Honda 2kvaThickness:...

610 x 330 x 540mm Aluminium Checker Ute Toolbox Trailer Camper Caravan Generator Tool Box for Honda 2kvaThickness:... -

700 x 450 x 650mm Aluminium Checker Ute Toolbox Trailer Camper Caravan Generator Tool BoxThickness:...

700 x 450 x 650mm Aluminium Checker Ute Toolbox Trailer Camper Caravan Generator Tool BoxThickness:... -

760 x 500 x 560mm Aluminium Checker Ute Toolbox Trailer Camper Caravan Generator Tool BoxThickness:...

760 x 500 x 560mm Aluminium Checker Ute Toolbox Trailer Camper Caravan Generator Tool BoxThickness:...

-

-

Trailer Boxes/Draw bar Boxes

>

-

Under Tray Toolboxes

>

- Accessories

-

Trailers Accessories

>

- Trailer Jockey Wheel >

-

Trailer Coupler

>

-

AU 2/3 Hole Quick Release 50 mm Non Braked CouplerSuits 50mm...

AU 2/3 Hole Quick Release 50 mm Non Braked CouplerSuits 50mm... -

AU 50 mm Mechanical Brake CouplerSuits 50mm...

AU 50 mm Mechanical Brake CouplerSuits 50mm... -

AU Electric Coupling 50 mm Towball 3.5T RatedSuits 50mm...

AU Electric Coupling 50 mm Towball 3.5T RatedSuits 50mm... -

NZ 1-7/8 Non Braked CouplerSuits 45mm...

NZ 1-7/8 Non Braked CouplerSuits 45mm... -

NZ 1-7/8 Mechanical Brake CouplerSuits 45mm...

NZ 1-7/8 Mechanical Brake CouplerSuits 45mm... -

NZ Electric Coupling 50 mm Towball 3.5T RatedSuits 50mm...

NZ Electric Coupling 50 mm Towball 3.5T RatedSuits 50mm...

-

-

Trailer Spring

>

-

Slipper to Eye Spring, 6×45×5

Slipper to Eye Spring, 6×45×5 -

Slipper to Eye Spring, 6×45×6

Slipper to Eye Spring, 6×45×6 -

Slipper to Eye Spring, 6×45×7

Slipper to Eye Spring, 6×45×7 -

Eye to Eye Spring, 8×45×5

Eye to Eye Spring, 8×45×5 -

Eye to Eye Spring, 8×45×7

Eye to Eye Spring, 8×45×7 -

Eye to Eye Spring 6×45×5

Eye to Eye Spring 6×45×5 -

Leaf Rocker Roller Spring, 6×60×7

Leaf Rocker Roller Spring, 6×60×7 -

Leaf Rocker Roller Spring, 6×60×9

Leaf Rocker Roller Spring, 6×60×9 -

Boat trailer Slipper to Eye Spring 6×45×5

Boat trailer Slipper to Eye Spring 6×45×5 -

Boat trailer Slipper to Eye Spring 6×45×7

Boat trailer Slipper to Eye Spring 6×45×7

-

- Trailer Axle >

- Trailer Brake >

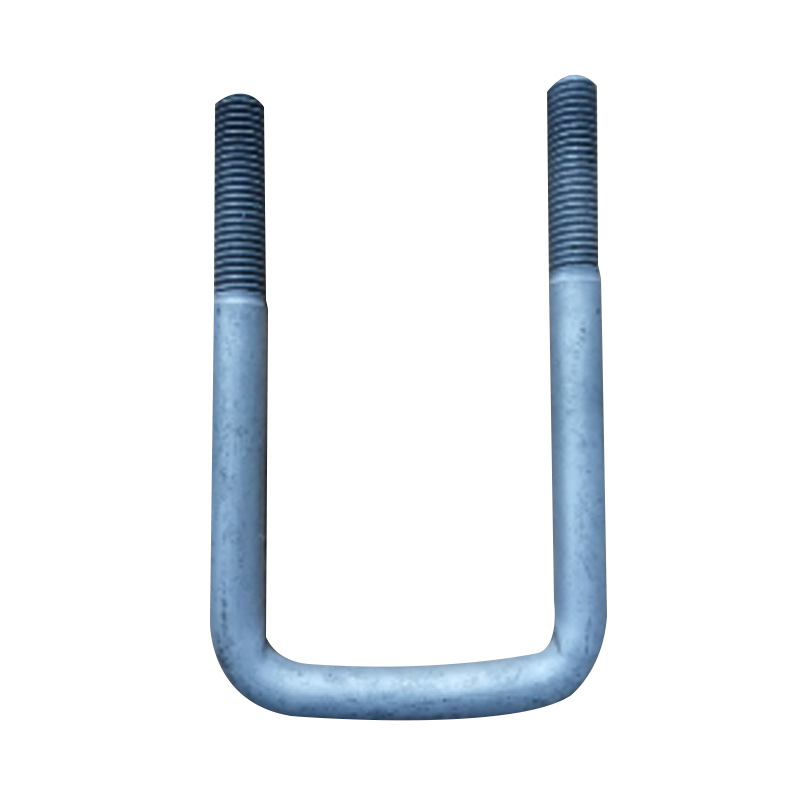

- Trailer U Bolt >

- Trailer Wheel >

-

Trailer Mudguard

>

-

13" Single Axle Galvanized Trailer MudguardThis 13-in...

13" Single Axle Galvanized Trailer MudguardThis 13-in... -

14" Single Axle Galvanized Trailer MudguardBuilt for ...

14" Single Axle Galvanized Trailer MudguardBuilt for ... -

14" Single Axle Galvanized Trailer Mudguard with Side StepThis 14-in...

14" Single Axle Galvanized Trailer Mudguard with Side StepThis 14-in... -

14" Single Axle Round Galvanized Trailer MudguardCrafted wi...

14" Single Axle Round Galvanized Trailer MudguardCrafted wi... -

14" Tandem Galvanized Trailer MudguardEngineered...

14" Tandem Galvanized Trailer MudguardEngineered... -

14" Tandem Aluminum Trailer MudguardThis 14-in...

14" Tandem Aluminum Trailer MudguardThis 14-in...

-

-

Trailer Light

>

-

LED Tail light M/Volt 107 x 99 mm 12/24V without Number Plate LightTrailer li...

LED Tail light M/Volt 107 x 99 mm 12/24V without Number Plate LightTrailer li... -

LED Tail light M/Volt 107 x 99 mm 12/24V with Number Plate LightTrailer li...

LED Tail light M/Volt 107 x 99 mm 12/24V with Number Plate LightTrailer li... -

White- LED SIDE Marker 60×38 mm M/Volt ClearTrailer si...

White- LED SIDE Marker 60×38 mm M/Volt ClearTrailer si... -

Yellow-LED SIDE Marker 59×35 mm M/Volt ClearTrailer si...

Yellow-LED SIDE Marker 59×35 mm M/Volt ClearTrailer si... -

Yellow & Red-LED SIDE 59×35 mm Marker M/Volt ClearTrailer si...

Yellow & Red-LED SIDE 59×35 mm Marker M/Volt ClearTrailer si... -

80×35 mm LED Number Plate LightTrailer nu...

80×35 mm LED Number Plate LightTrailer nu... -

70×30 mm Reflector Stick On AmberReflectors...

70×30 mm Reflector Stick On AmberReflectors... -

70×30 mm Reflector Stick On RedReflectors...

70×30 mm Reflector Stick On RedReflectors... -

70×30 mm Reflector Stick On ClearReflectors...

70×30 mm Reflector Stick On ClearReflectors...

-

- Trailer Cage >

- Trailer Canvas Cover >

-

Trailer Drawbar Toolbox

>

-

Side Open Trailer Drawbar Aluminum Toolbox with Fridge Slideavaiable f...

Side Open Trailer Drawbar Aluminum Toolbox with Fridge Slideavaiable f... -

Top Opening Trailer Drawbar Aluminum Toolboxavaiable f...

Top Opening Trailer Drawbar Aluminum Toolboxavaiable f... -

Checker Top Opening Trailer Drawbar Aluminum Toolboxavaiable f...

Checker Top Opening Trailer Drawbar Aluminum Toolboxavaiable f... -

3/4 Angle Toolbox Trailer Drawbar Aluminum Toolboxavaiable f...

3/4 Angle Toolbox Trailer Drawbar Aluminum Toolboxavaiable f... -

Aluminum Trailer Tongue Storage Toolbox with Lockavaiable f...

Aluminum Trailer Tongue Storage Toolbox with Lockavaiable f... -

Checker 3 Lid Ute Toolbox Trailer Drawbar Aluminum Toolboxavaiable f...

Checker 3 Lid Ute Toolbox Trailer Drawbar Aluminum Toolboxavaiable f... -

Aluminium 3 Lid Slides Trailer Drawbar Toolbox with Fridge Slideavaiable f...

Aluminium 3 Lid Slides Trailer Drawbar Toolbox with Fridge Slideavaiable f... -

Black Aluminium Ute Toolbox Fridge Slide Trailer Drawbar Toolboxavaiable f...

Black Aluminium Ute Toolbox Fridge Slide Trailer Drawbar Toolboxavaiable f... -

Black Trailer Drawbar Aluminum Toolbox with Fridge Slideavaiable f...

Black Trailer Drawbar Aluminum Toolbox with Fridge Slideavaiable f... -

Gullwing 2 Lid Trailer Drawbar Aluminum Toolboxavaiable f...

Gullwing 2 Lid Trailer Drawbar Aluminum Toolboxavaiable f... -

Checker Flat Top Dual 2 Lid Trailer Drawbar Aluminum Toolboxavaiable f...

Checker Flat Top Dual 2 Lid Trailer Drawbar Aluminum Toolboxavaiable f... -

Full Side Opening Door Trailer Drawbar Aluminum Toolboxavaiable f...

Full Side Opening Door Trailer Drawbar Aluminum Toolboxavaiable f...

-

- Trailer Mower Box >

- Trailer H Bar >

- Trailer Spare Wheel Holder >

-

Toolbox Accessories

>

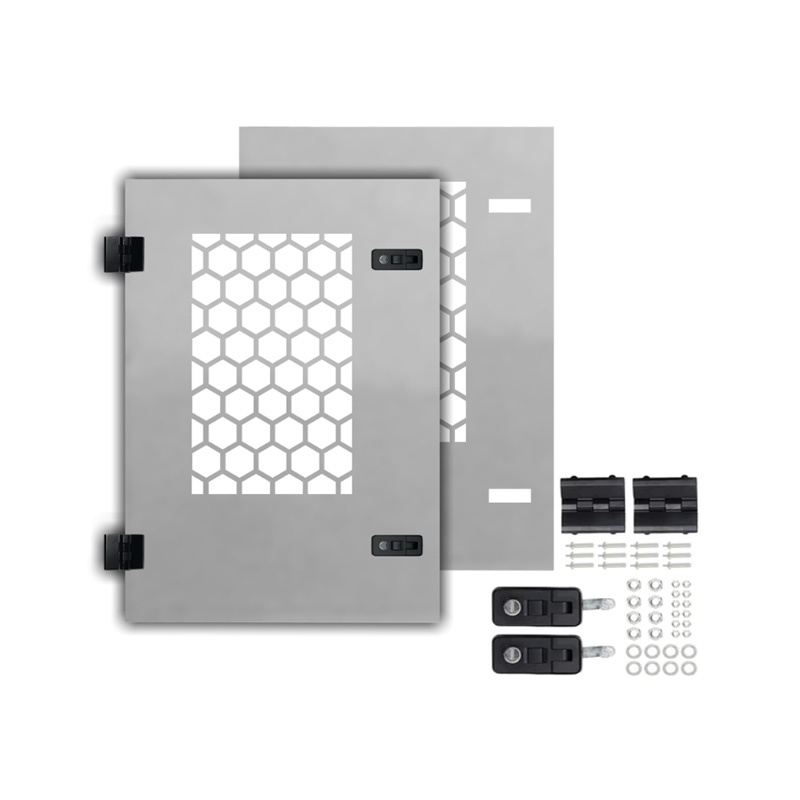

- Toolbox Mounting Kit >

-

Toolbox Locks

>

-

Stainless Steel T-Lock STUD MountMaterial: ...

Stainless Steel T-Lock STUD MountMaterial: ... -

12V Recessed Folding Padlock Friendly Whale Tail Handle ACT-WTLOCKKey lockin...

12V Recessed Folding Padlock Friendly Whale Tail Handle ACT-WTLOCKKey lockin... -

Whale Tail T-Lock Padlockable Whale Tail HandleKey lockin...

Whale Tail T-Lock Padlockable Whale Tail HandleKey lockin... -

Black Whale Tail T-Lock Padlockable Whale Tail HandleKey lockin...

Black Whale Tail T-Lock Padlockable Whale Tail HandleKey lockin... -

Chome & Black Whale Tail T-Lock Padlockable Whale Tail HandleKey lockin...

Chome & Black Whale Tail T-Lock Padlockable Whale Tail HandleKey lockin... -

White Whale Tail T-Lock Padlockable Whale Tail HandleKey lockin...

White Whale Tail T-Lock Padlockable Whale Tail HandleKey lockin...

-

-

Toolbox Drawer Unites

>

-

600 x 430 x 450mm Black Aluminium 3 Drawer Unit for Ute Truck Tool box Canopy Caravan Tool BoxThickness:...

600 x 430 x 450mm Black Aluminium 3 Drawer Unit for Ute Truck Tool box Canopy Caravan Tool BoxThickness:... -

600 x 430 x 620mm Black Aluminium 4 Drawer Unit for Ute Truck Tool box Canopy Caravan Tool BoxThickness:...

600 x 430 x 620mm Black Aluminium 4 Drawer Unit for Ute Truck Tool box Canopy Caravan Tool BoxThickness:... -

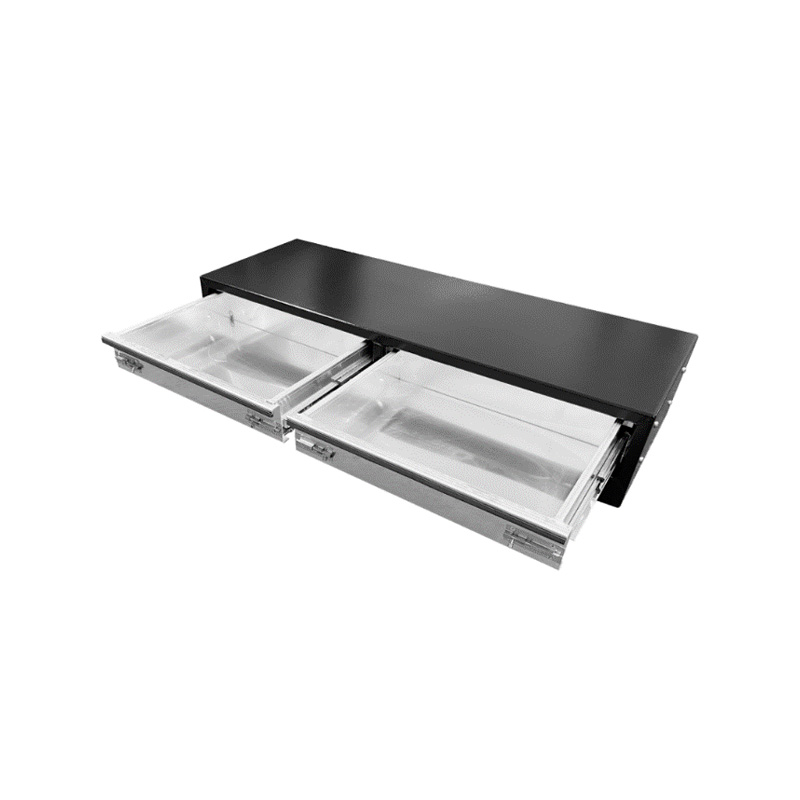

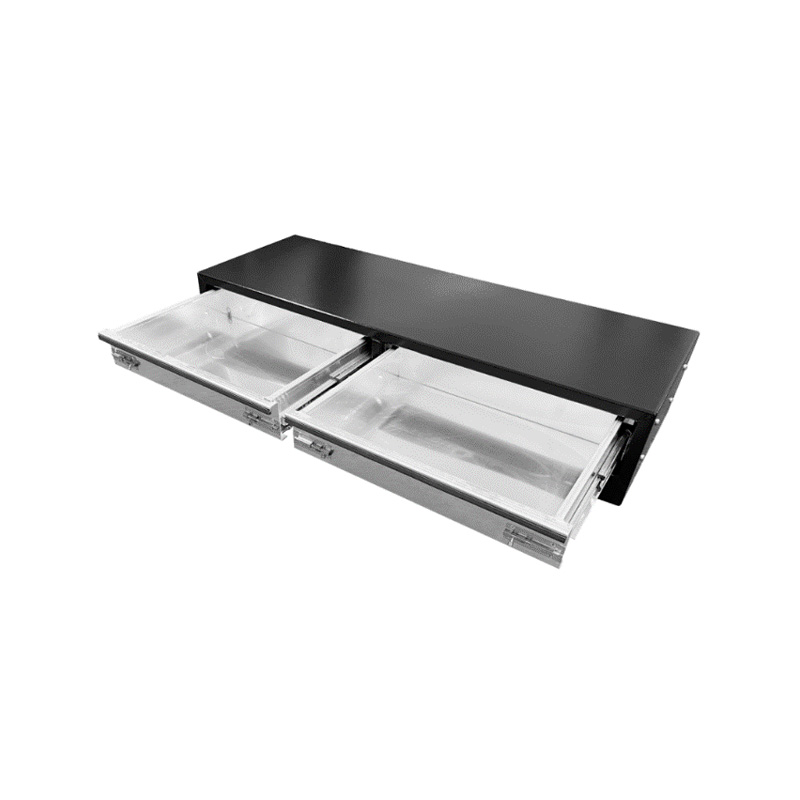

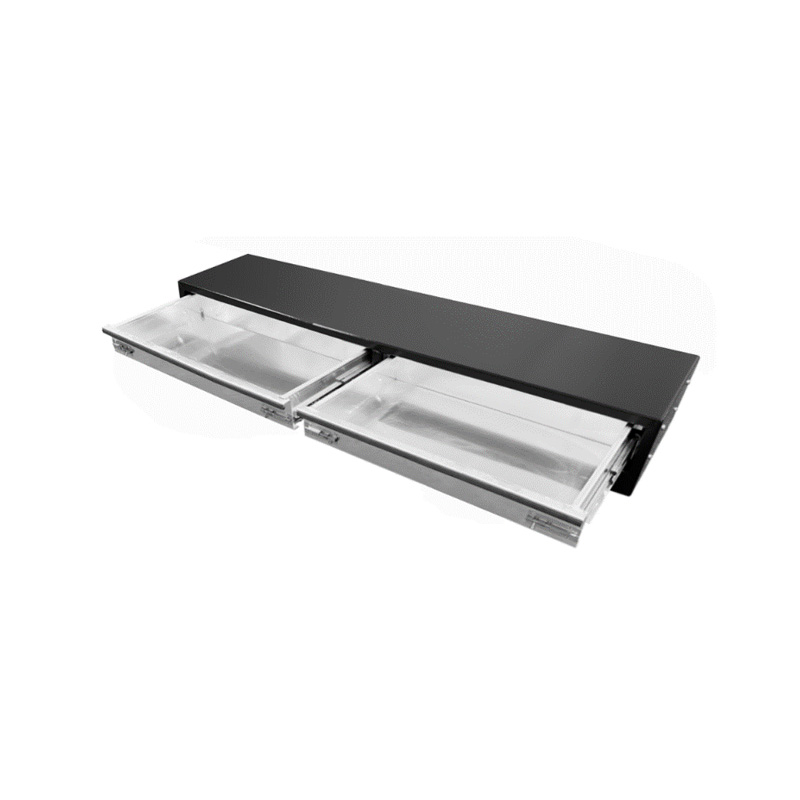

1020 x 440 x 230mm Black Aluminium 2 Drawer Unit for Ute Truck Tool box Canopy Caravan ToolboxThickness:...

1020 x 440 x 230mm Black Aluminium 2 Drawer Unit for Ute Truck Tool box Canopy Caravan ToolboxThickness:... -

1220 x 440 x 230mm Black Aluminium 2 Drawer Unit for Ute Truck Tool box Canopy Caravan ToolboxThickness:...

1220 x 440 x 230mm Black Aluminium 2 Drawer Unit for Ute Truck Tool box Canopy Caravan ToolboxThickness:... -

520 x 440 x 230mm Black Aluminium 2 Drawer Unit for Ute Truck Tool box Canopy Caravan ToolboxThickness:...

520 x 440 x 230mm Black Aluminium 2 Drawer Unit for Ute Truck Tool box Canopy Caravan ToolboxThickness:... -

1920 x 440 x 230mm Black Aluminium 2 Drawer Unit for Ute Truck Tool box Canopy Caravan Tool BoxThickness:...

1920 x 440 x 230mm Black Aluminium 2 Drawer Unit for Ute Truck Tool box Canopy Caravan Tool BoxThickness:... -

1400 x 600 x 380mm 1 Drawer Unit for Ute Truck Tool box Canopy Caravan ToolboxThickness:...

1400 x 600 x 380mm 1 Drawer Unit for Ute Truck Tool box Canopy Caravan ToolboxThickness:... -

1400 x 600 x 380mm 2 Drawer Unit for Ute Truck Tool box Canopy Caravan ToolboxThickness:...

1400 x 600 x 380mm 2 Drawer Unit for Ute Truck Tool box Canopy Caravan ToolboxThickness:... -

1700 x 600 x 380mm 3 Drawer Unit for Ute Truck Tool box Canopy Caravan ToolboxThickness:...

1700 x 600 x 380mm 3 Drawer Unit for Ute Truck Tool box Canopy Caravan ToolboxThickness:... -

1900 x 600 x 380mm 3 Drawer Unit for Ute Truck Tool box Canopy Caravan ToolboxThickness:...

1900 x 600 x 380mm 3 Drawer Unit for Ute Truck Tool box Canopy Caravan ToolboxThickness:... -

1.4m Aluminium Ute Tool box Under Tray Toolbox Trundle Roller Tray Slide Out Drawer Toolbox Benchtop LidThickness:...

1.4m Aluminium Ute Tool box Under Tray Toolbox Trundle Roller Tray Slide Out Drawer Toolbox Benchtop LidThickness:... -

1.6m Aluminium Ute Tool box Under Tray Toolbox Trundle Roller Tray Slide Out Drawer Toolbox Benchtop LidThickness:...

1.6m Aluminium Ute Tool box Under Tray Toolbox Trundle Roller Tray Slide Out Drawer Toolbox Benchtop LidThickness:... -

1.7m Aluminium Ute Tool box Under Tray Toolbox Trundle Roller Tray Slide Out Drawer Toolbox Benchtop LidThickness:...

1.7m Aluminium Ute Tool box Under Tray Toolbox Trundle Roller Tray Slide Out Drawer Toolbox Benchtop LidThickness:...

-

-

Toolbox Shelves

>

-

0.9m Shelf - For Aluminium Storage Toolbox Tool BoxThickness:...

0.9m Shelf - For Aluminium Storage Toolbox Tool BoxThickness:... -

1.2m Shelf - For Aluminium Storage Toolbox Tool BoxThickness:...

1.2m Shelf - For Aluminium Storage Toolbox Tool BoxThickness:... -

1.4m Shelf - For Aluminium Storage Toolbox Tool BoxThickness:...

1.4m Shelf - For Aluminium Storage Toolbox Tool BoxThickness:... -

1.5m Shelf - For Aluminium Storage Toolbox Tool BoxThickness:...

1.5m Shelf - For Aluminium Storage Toolbox Tool BoxThickness:... -

1.6m Shelf - For Aluminium Storage Toolbox Tool BoxThickness:...

1.6m Shelf - For Aluminium Storage Toolbox Tool BoxThickness:... -

1.7m Shelf - For Aluminium Storage Toolbox Tool BoxThickness:...

1.7m Shelf - For Aluminium Storage Toolbox Tool BoxThickness:... -

1.8m Shelf - For Aluminium Storage Toolbox Tool BoxThickness:...

1.8m Shelf - For Aluminium Storage Toolbox Tool BoxThickness:... -

1.9m Shelf - For Aluminium Storage Toolbox Tool BoxThickness:...

1.9m Shelf - For Aluminium Storage Toolbox Tool BoxThickness:... -

1.94m Shelf - For Aluminium Storage Toolbox Tool BoxThickness:...

1.94m Shelf - For Aluminium Storage Toolbox Tool BoxThickness:... -

2.1m Shelf - For Aluminium Storage Toolbox Tool BoxThickness:...

2.1m Shelf - For Aluminium Storage Toolbox Tool BoxThickness:...

-

-

Gas Strut

>

-

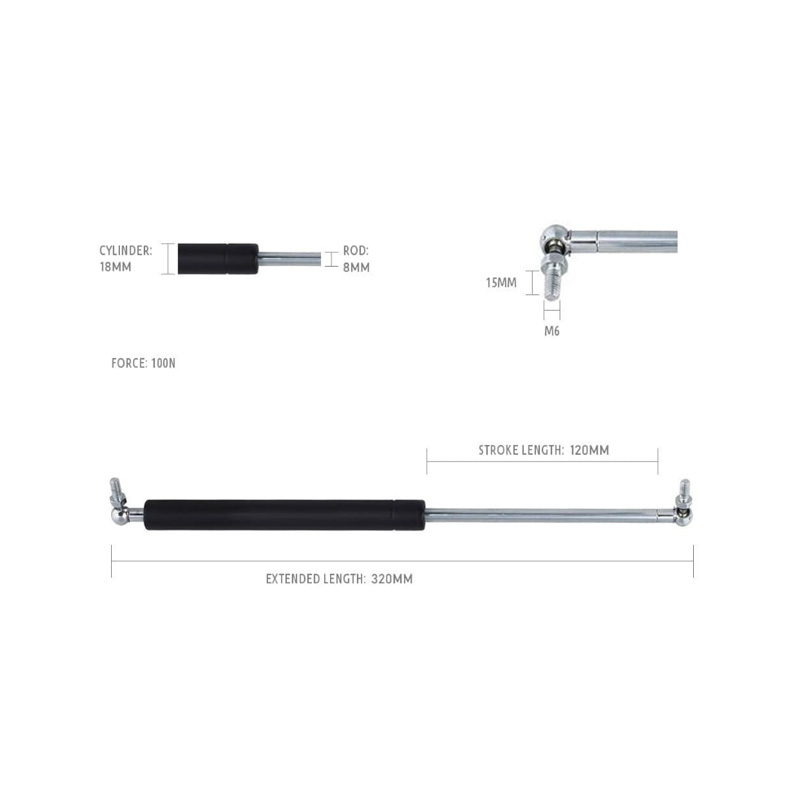

Gas Strut 120-320/100N GS120-320-100NExtended L...

Gas Strut 120-320/100N GS120-320-100NExtended L... -

Gas Strut 120-320/180N GS120-320-180NExtended L...

Gas Strut 120-320/180N GS120-320-180NExtended L... -

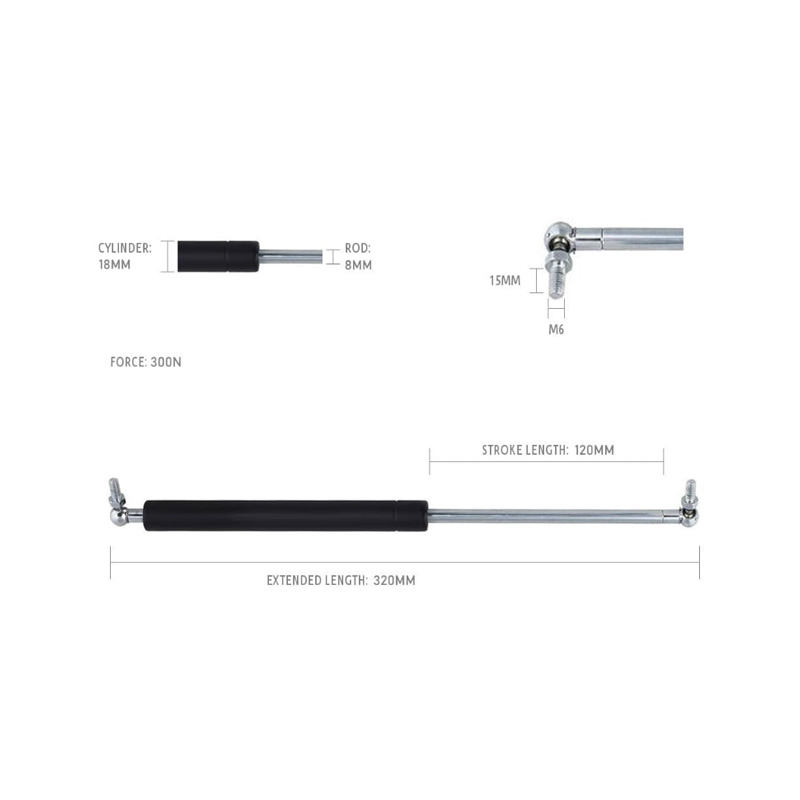

Gas Strut 120-320/300N GS120-320-300NExtended L...

Gas Strut 120-320/300N GS120-320-300NExtended L... -

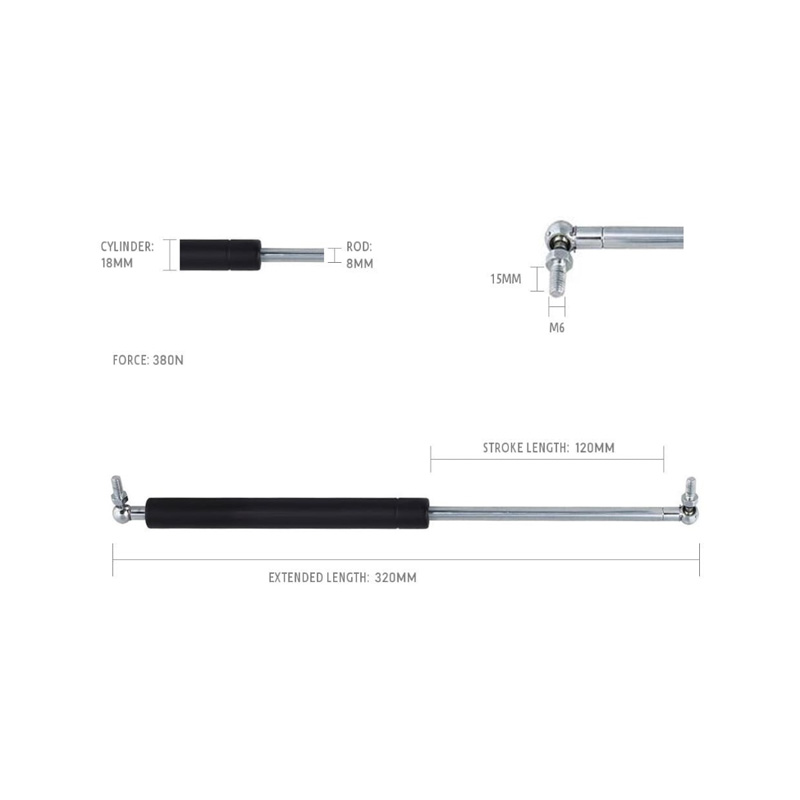

Gas Strut 120-320/380N GS120-320-380NExtended L...

Gas Strut 120-320/380N GS120-320-380NExtended L... -

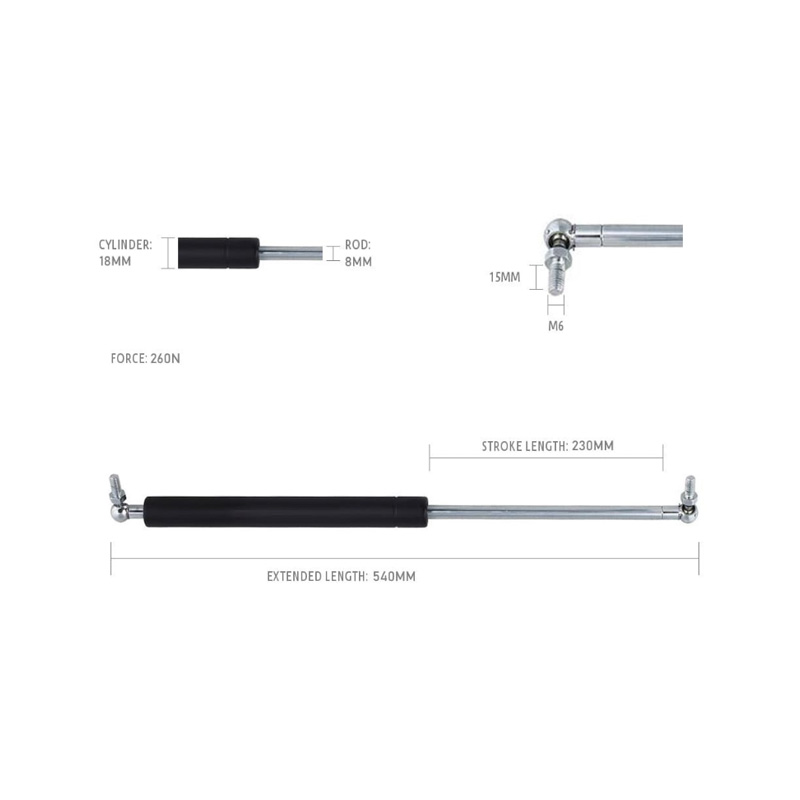

Gas Strut 230-540/260N GS230-540-260NExtended L...

Gas Strut 230-540/260N GS230-540-260NExtended L... -

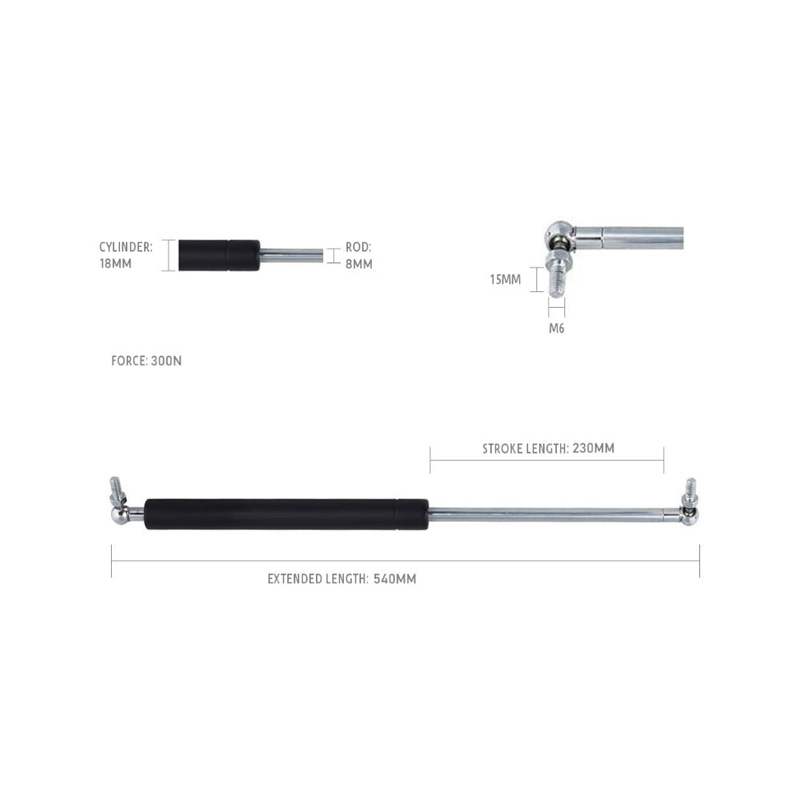

Gas Strut 230-540/300N GS230-540-300NExtended L...

Gas Strut 230-540/300N GS230-540-300NExtended L... -

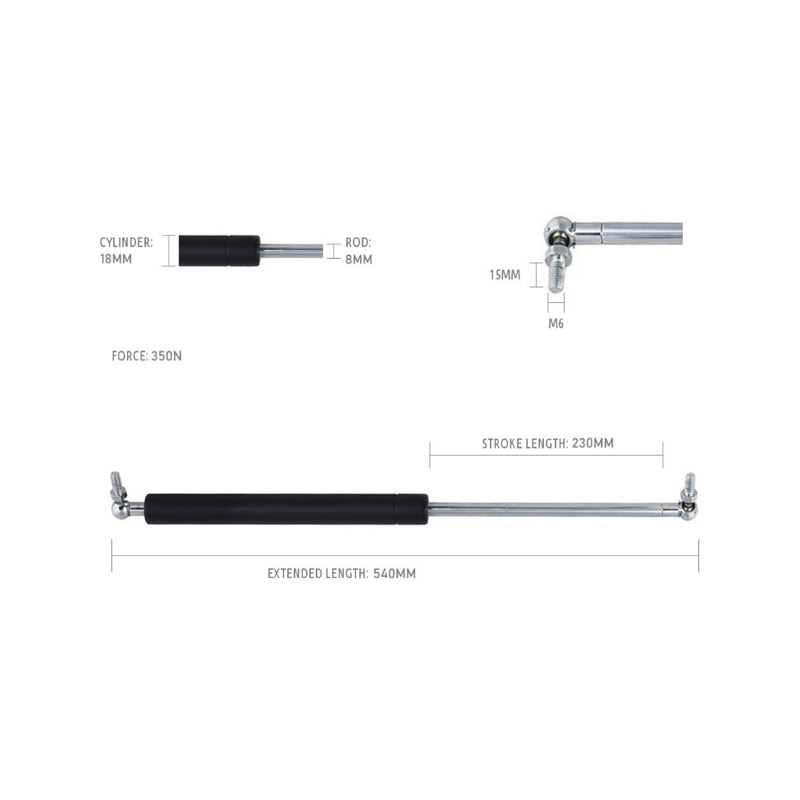

Gas Strut 230-540/350N GS230-540-350NExtended L...

Gas Strut 230-540/350N GS230-540-350NExtended L... -

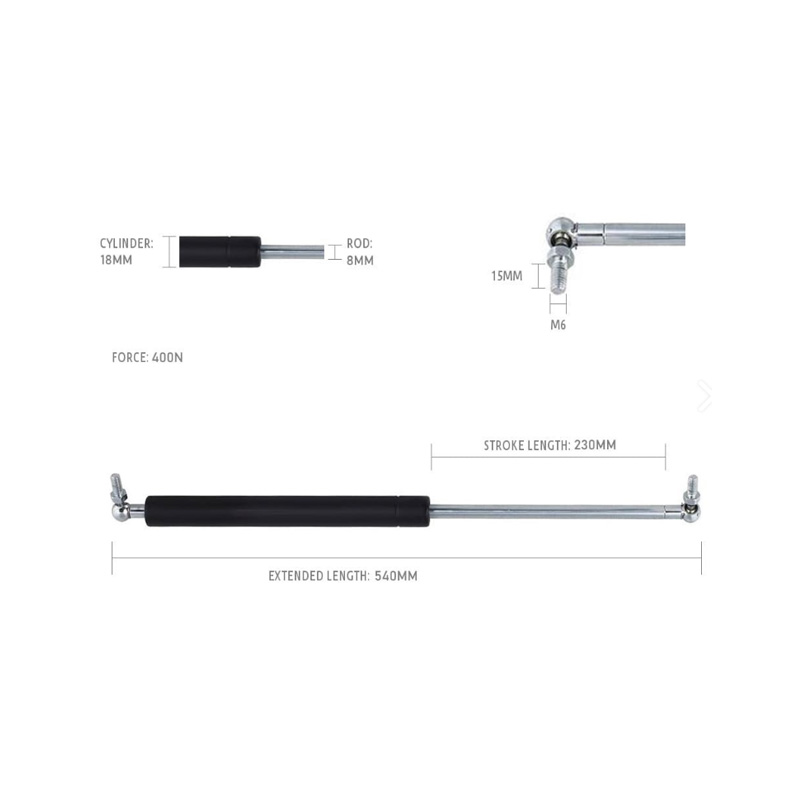

Gas Strut 230-540/400N GS230-540-400NExtended L...

Gas Strut 230-540/400N GS230-540-400NExtended L...

-

- Ladder Rack >

- Canopy Ladder >

- Toolbox Cargo Cage >

- Toolbox Rear Gate >

-

Fuel Gas Tool Holder

>

-

600 x 230 x 290mm Aluminium Tool Storage Handle Holder Heavy Duty ToteThickness:...

600 x 230 x 290mm Aluminium Tool Storage Handle Holder Heavy Duty ToteThickness:... -

320 x 320 x 320mm Aluminium Checker Camping Camper 4x4 Ute Truck Trailer Gas Bottle HolderSize Lengt...

320 x 320 x 320mm Aluminium Checker Camping Camper 4x4 Ute Truck Trailer Gas Bottle HolderSize Lengt... -

450 x 230 x 300mm Aluminium Checker Camping Camper 4x4 Ute Truck Acetylene Oxy Gas Bottle Holder with DividerThickness:...

450 x 230 x 300mm Aluminium Checker Camping Camper 4x4 Ute Truck Acetylene Oxy Gas Bottle Holder with DividerThickness:... -

450 x 230 x 380mm Aluminium Camping 4x4 Ute Truck Acetylene Oxy Gas Bottle Holder with DividerThickness:...

450 x 230 x 380mm Aluminium Camping 4x4 Ute Truck Acetylene Oxy Gas Bottle Holder with DividerThickness:... -

450 x 230 x 300mm Aluminium Checker Camping Camper 4x4 Ute Truck Acetylene Oxy Gas Bottle HolderThickness:...

450 x 230 x 300mm Aluminium Checker Camping Camper 4x4 Ute Truck Acetylene Oxy Gas Bottle HolderThickness:... -

450 x 230 x 380mm Aluminium Camping 4x4 Ute Truck Acetylene Oxy Gas Bottle HolderSize Lengt...

450 x 230 x 380mm Aluminium Camping 4x4 Ute Truck Acetylene Oxy Gas Bottle HolderSize Lengt... -

400 x 220 x 500mm Checker Aluminium Ute Camping Camper Jerry Can Bottle Holder Pad lockable Tool BoxThickness:...

400 x 220 x 500mm Checker Aluminium Ute Camping Camper Jerry Can Bottle Holder Pad lockable Tool BoxThickness:... -

335 x 285 x 400mm 4.5kg Aluminium Gas Bottle HolderThickness:...

335 x 285 x 400mm 4.5kg Aluminium Gas Bottle HolderThickness:... -

361 x 196 x 303mm Flat Aluminium Ute Camping Camper Jerry Can Bottle Holder Tool BoxThickness:...

361 x 196 x 303mm Flat Aluminium Ute Camping Camper Jerry Can Bottle Holder Tool BoxThickness:...

-

- Jack off Legs >

-

Trailers Accessories

>

- About

- News

- Contact

Web Menu

- Home

- TRAILERS

- TOOLBOXES

- ACCESSORIES

- About

- News

- Contact Us

Product Search

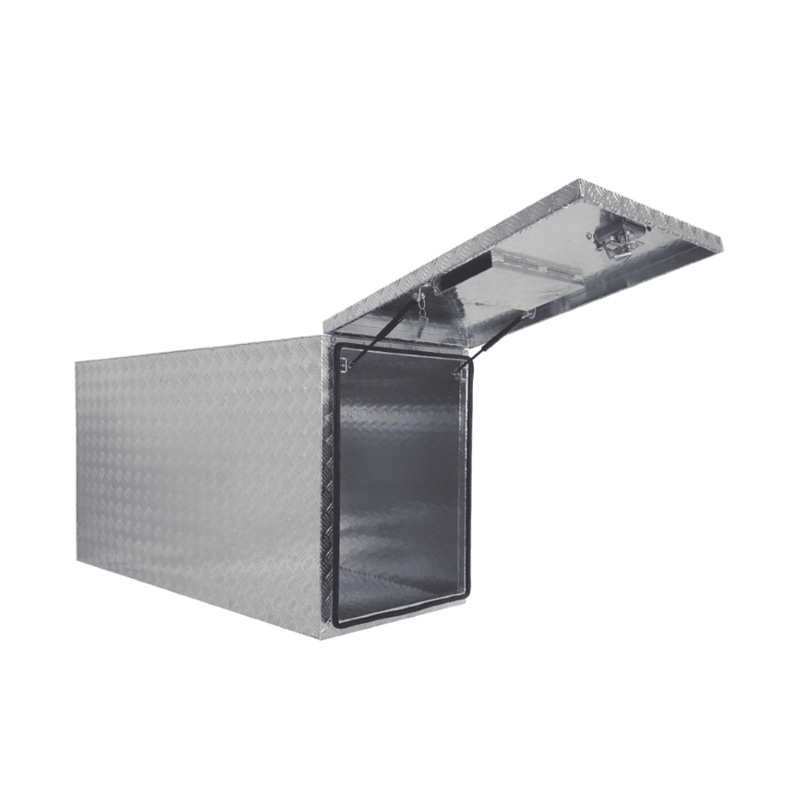

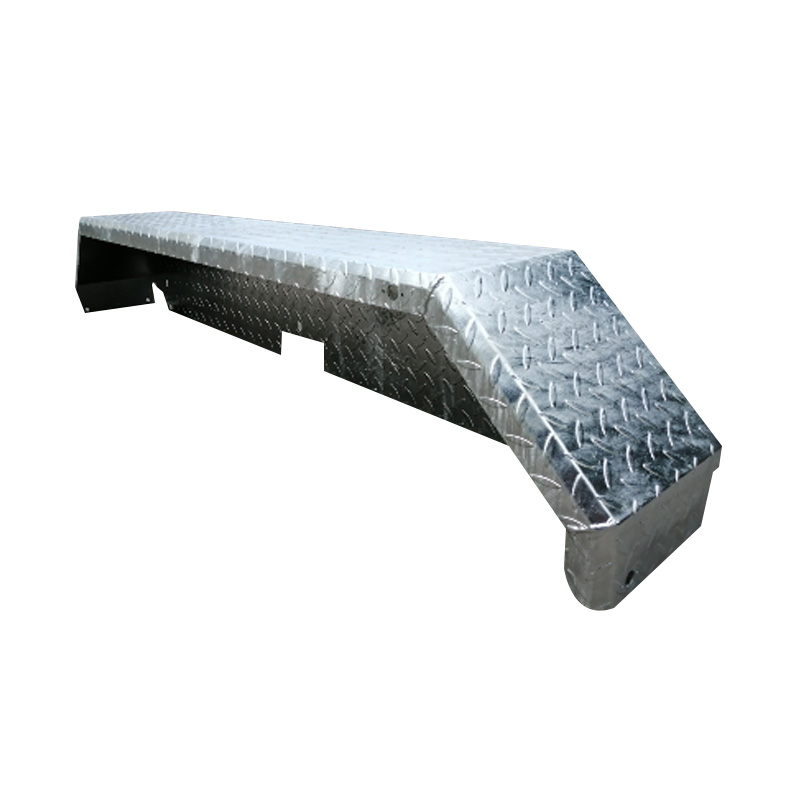

Understanding Full Opening Door Truck Boxes

Full opening door truck boxes are widely used storage solutions for pickup trucks and commercial vehicles. They are designed with doors that open across the full face of the box, allowing direct access to tools and equipment without reaching deep into the compartment. These boxes are commonly installed on trays, flatbeds, or service bodies and are used in construction, maintenance, logistics, and agriculture.

What Is a Full Opening Door Truck Box?

A full opening door truck box is a storage unit mounted on a truck tray or body, featuring one or more doors that open nearly the entire width and height of the box. Unlike partial-access toolboxes, which use small lids or hatches, full opening door designs allow users to see and reach most stored items at once.

These boxes are typically constructed from steel or aluminum. Steel versions are valued for structural rigidity, while aluminum boxes are often selected to reduce added vehicle weight. The doors are usually hinged on the sides or top and supported by mechanical stays or gas struts to hold them open during use.

The primary function of this design is to improve accessibility. When tools or components are stored in a deep box, limited openings can slow work and increase the risk of injury from awkward lifting. Full opening doors reduce these issues by providing a clear, unobstructed entry to the storage space.

What Are the Common Applications of Full Opening Door Truck Boxes?

Full opening door truck boxes are used across a wide range of industries where mobile storage is required. Trades such as electrical installation, plumbing, and mechanical repair often rely on these boxes to carry hand tools, power tools, fittings, and spare parts. The ability to access equipment quickly on job sites supports more efficient task completion.

In fleet and service operations, these boxes are commonly installed on utility vehicles used for infrastructure maintenance, roadside assistance, or facility support. Organized storage helps standardize vehicle setups across a fleet, making it easier for different operators to locate tools.

Agricultural and rural users also adopt full opening door truck boxes to store equipment, fasteners, and maintenance supplies. In these environments, the full opening design helps reduce time spent unloading items to reach those stored at the back of the box. Overall, the application is driven by the need for clear access, organization, and protection during transport.

What Materials and Construction Features Are Typically Used?

Most full opening door truck boxes are manufactured from metal, with aluminum and steel being the most common options. Aluminum is corrosion-resistant and lighter, which can help preserve vehicle payload capacity. Steel provides higher resistance to impact and deformation, which may be relevant in demanding work environments.

Construction features often include reinforced door frames, welded seams, and internal bracing to maintain structural stability. Doors are usually fitted with rubber seals to limit water and dust ingress. While these seals improve protection, their effectiveness depends on manufacturing quality and correct installation.

Locking systems are another key feature. Many boxes use compression locks or paddle latches that pull the door firmly against the seal when closed. Some designs allow for integration with vehicle central locking systems, while others rely on independent mechanical locks. The choice of features often reflects the intended usage, security requirements, and budget constraints.

What Should Be Considered When Choosing a Full Opening Door Truck Box?

When selecting a full opening door truck box, several practical factors should be evaluated. Size and layout are primary considerations. The box dimensions should match the available space on the truck tray and align with the type of equipment being stored. Internal shelving or dividers may be needed for smaller items, while open layouts may suit larger tools.

Weight is another important factor. Adding a truck box increases the overall vehicle mass, which reduces available payload. Buyers should check the box weight and ensure that the combined load remains within the vehicle’s rated limits. In some cases, suspension upgrades may be required.

Environmental exposure should also be considered. Vehicles operating in wet, dusty, or coastal conditions may require higher attention to sealing and corrosion resistance. Regular inspection of door seals and hinges can help maintain performance over time.

Post a comment

- GET A QUOTE

- PRODUCTS

- TRAILERS

- TOOLBOXES

- ACCESSORIES

- CONTACT US

-

-

+86-0579-82795522

+86-0579-82795522 -

+86-13362901332(Jack)

+86-13362901332(Jack)

-

-

No. 1533 Huaxi Road, Jinhua City, Zhejiang Province, China

No. 1533 Huaxi Road, Jinhua City, Zhejiang Province, China

-

- MOBILE SITE

English

English  Español

Español  русский

русский